Play all audios:

ABSTRACT Wearable electronics, as essential components of the Internet of Things (IoT), have attracted widespread attention, and the trend is to configure attractive wearable smart

microsystems by integrating sensing, powering, and other functions. Herein, we developed an elastic hybrid triboelectric–electromagnetic microenergy harvester (named EHTE) to realize hybrid

sensing and microenergy simultaneously. This EHTE is a highly integrated triboelectric nanogenerator (TENG) and electromagnetic nanogenerator (EMG). Based on the

triboelectric–electromagnetic hybrid mechanism, an enhanced electrical output of the EHTE was achieved successfully, which demonstrates the feasibility of the EHTE for microelectronics

powering. Moreover, with the merits of the EMG, the developed hybrid microenergy harvester integrated both active frequency sensing and passive inductive sensing capabilities. Specifically,

the almost linear correlation of the electromagnetic outputs to the frequencies of the external stimulus endowed the proposed EHTE with an outstanding active frequency sensing ability. In

addition, due to the unique structural configuration of the EMG (i.e., a conductive permanent magnet (PM), hybrid deformation layer, and flexible printed circuit board (FPCB) coil), an

opportunity was provided for the developed EHTE to serve as a passive inductive sensor based on the eddy current effect (i.e., a form of electromagnetic induction). Therefore, the developed

EHTE successfully achieved the integration of hybrid sensing (i.e., active frequency sensing and passive inductive sensing) and microenergy (i.e., the combination of electromagnetic effect

and triboelectric effect) within a single device, which demonstrates the potential of this newly developed EHTE for wearable electronic applications, especially in applications of compact

active microsystems. SIMILAR CONTENT BEING VIEWED BY OTHERS HIGH-PERFORMANCE HYBRID NANOGENERATOR FOR SELF-POWERED WIRELESS MULTI-SENSING MICROSYSTEMS Article Open access 21 July 2023

FILLING THE GAP BETWEEN TOPOLOGICAL INSULATOR NANOMATERIALS AND TRIBOELECTRIC NANOGENERATORS Article Open access 17 February 2022 MAGNETOELECTRIC MICROELECTROMECHANICAL AND

NANOELECTROMECHANICAL SYSTEMS FOR THE IOT Article 07 May 2024 INTRODUCTION As one of the essential components of next-generation information technologies, the Internet of Things (IoT)1,2 is

regarded as an important component for the development of modern society in various sectors, including industry, economic activity, transportation, and security. Although the IoT has

experienced advanced development in recent years, challenges still exist in meeting the increasing demands on quality of life, especially for the energy supply problems of the IoT sensing

network. As the key interface media between the environment and client, the sensing network consists of trillions of distributed sensors for environmental stimulus collection and

transduction, in which the power consumption of individual sensors is low but the energy requirements of the total sensing network can be large, on the order of billions of watts. Thus, how

to sustainably power sensing networks has become an urgent issue for the further development of the IoT. One of the most effective approaches is harvesting micro/nano energy from the ambient

environment, where diverse energy sources are widely distributed in various forms, such as solar, heat, wind, and vibration. Therefore, a massive effort has been devoted to developing

different kinds of micro/nano energy harvesters based on different energy harvesting technologies, including photovoltaic nanogenerators (PVNGs)3,4,5, thermoelectric generators (ThEGs)6,7,8,

electromagnetic generators (EMGs)9,10,11, piezoelectric nanogenerators (PENGs)12,13,14, triboelectric nanogenerators (TENGs)15,16,17,18,19, and many others20,21,22,23. However, different

kinds of energy harvesting technology have unique working conditions and output properties24. For example, light and temperature differences are indispensable working conditions for PVNGs

and ThEGs, respectively, but their DC outputs provide a great advantage for wearable electronics powering. For EMGs, the bulk permanent magnet (PM) and coil are two essential components to

realize EMGs with high output, but bulky and heavy EMGs are inconvenient to wear. Although flexible EMGs using ferroelastomer materials or flexible coils have already been proposed to

address weight and size issues, the output was sacrificed. In addition, organic or inorganic piezoelectric materials and complex manufacturing processes, e.g., polarization treatment, should

be required to form PENGs. In comparison, TENGs, with advantages such as no material limitations, high output power and high energy conversion efficiency, have attracted more attention in

the IoT, particularly in portable and wearable electronic fields. Thus, great effort has been made to develop different kinds of high-performance TENGs, serving as robust power

sources25,26,27,28 and/or self-powered sensors29,30,31. With the proposal of hybrid energy harvesters, the potential of TENGs has been explored in recent years32. By integrating a TENG with

other energy harvesting technologies in a single device, e.g., hybrid triboelectric–photovoltaic nanogenerators33,34,35, hybrid triboelectric–piezoelectric nanogenerators36,37,38, hybrid

triboelectric–electromagnetic nanogenerators39,40,41,42,43, hybrid triboelectric–piezoelectric–pyroelectric nanogenerators44, etc.45, multiplex electrical outputs can be generated from a

single stimulus input, thus enhancing the energy conversion efficiency and enlarging the total output power of these devices. Moreover, hybrid devices can realize functional integration or

complementarity. For example, Guo et al. developed all-fiber hybrid piezoelectric-enhanced triboelectric nanogenerators that not only achieved enhanced electrical output but also active

motion sensing for real-time fall detection36. Wan et al. proposed a flexible hybridized electromagnetic–triboelectric nanogenerator for mechanical energy harvesting and 3D trajectory

sensing42. Wang et al. demonstrated a complementary electromagnetic–triboelectric active sensor for detecting triggering force and velocity simultaneously. In this work, we developed an

elastic hybrid triboelectric–electromagnetic microenergy harvester (named EHTE), which not only adopted the advantages of several triboelectric–electromagnetic hybrid microenergy harvesters

with hybrid and enhanced outputs but also highly integrated active frequency sensing and passive inductive pressure sensing within a single device. Based on the coupling of the triboelectric

effect and electromagnetic effect, the EHTE exhibited remarkable triboelectric and electromagnetic outputs and hybrid output for microelectronics powering. This EHTE was successfully

demonstrated to directly/indirectly power light-emitting diode (LED) screens and calculators, revealing the attractive potential for micro/nano powering. For hybrid sensing, the proposed

EHTE could achieve active frequency sensing in terms of the linear correlation of electromagnetic outputs to frequencies of the external stimulus. In addition, due to the unique structural

configuration of the electromagnetic nanogenerator of the EHTE, the feasibility of serving as an inductive sensor for passive sensing is provided. Herein, the inductive response behaviors of

the proposed EHTE are caused by the eddy current effect46,47, which is a form of electromagnetic induction. Thus, with the merits of the hybridization of this triboelectric nanogenerator

and electromagnetic nanogenerator, this newly developed EHTE successfully realized the integration of hybrid sensing (i.e., active frequency sensing and passive inductive sensing) and

microenergy (i.e., triboelectric–electromagnetic hybrid microenergy) in compact form, exhibiting promising potential for active microsystem applications. RESULTS AND DISCUSSION

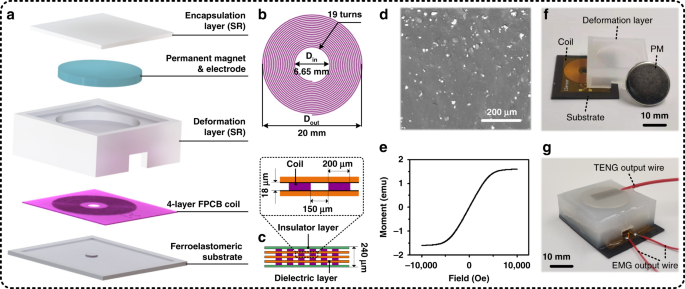

CHARACTERIZATION OF THE DEVELOPED EHTE Figure 1a illustrates an exploded view of the elastic hybrid triboelectric–electromagnetic microenergy harvester (EHTE), which consists of an

FeSiAl/silicone rubber (FeSiAl/SR) ferroelastomeric substrate, a 4-layer FPCB coil (FPCB is the acronym for flexible printed circuit board), a hybrid silicone rubber–air (SR-air) deformation

layer, a permanent magnet (PM) and a silicone rubber (SR) encapsulation layer. The 4-layer FPCB coil, hybrid SR-air deformation layer and PM were the main components of the triboelectric

nanogenerator of the EHTE, in which the polyimide (PI) on the top surface of the 4-layer FPCB coil and SR on the bottom surface of the deformation layer were used as triboelectric pairs, and

the PM was used as the electrode. Moreover, the FeSiAl/SR ferroelastomeric substrate, 4-layer FPCB coil, hybrid SR-air deformation layer and PM formed the electromagnetic nanogenerator of

the EHTE. These discrete components have unique properties. As shown in Fig. 1a, this deformation layer had different grooves on its upper and lower layers. The upper layer was used to fix

the PM, and the lower layer was mainly used as an air medium layer for the triboelectric nanogenerator. Notably, the sheet resistance of the PM was 0.36 MΩ/sq, and its magnetic field

intensity was ~110.63 mT. As a result, the PM served as the conductive electrode of the triboelectric nanogenerator as well as the magnet of the electromagnetic nanogenerator in the hybrid

microenergy harvester. For the 4-layer FPCB coil, Fig. 1b illustrates the top view of one of the layers of the FPCB coil. Each layer had an outer diameter of 20 mm, an inner diameter of 6.65

mm and 19 turns. This means that the total number of turns of the FPCB coil was 76. There was a 3 mm-diameter hole in the 4-layer FPCB coil, which was filled by the FeSiAl/SR ferroelastomer

to improve the magnetic flux of the coil. Figure 1c illustrates the cross-sectional view of the 4-layer FPCB coil. The thickness of the whole FPCB coil was 240 μm, the thickness of the

copper trace was 18 μm, and the width and space of the copper trace were 200 and 150 μm, respectively. The FeSiAl/SR ferroelastomeric substrate was another crucial component of the hybrid

microenergy harvester. Figure 1d shows the surface morphology of the ferroelastomeric substrate with a 50 wt% proportion of FeSiAl particles, in which the FeSiAl particles were well

distributed within the silicone rubber matrix. It is noted that the smaller FeSiAl particles observed in the ferroelastomer are due to particles that were semi/fully embedded in the silicone

rubber matrix. To confirm the ferromagnetic property of the FeSiAl/SR ferroelastomeric substrate, the magnetic hysteresis loop of the substrate was measured using a vibrating sample

magnetometer, as illustrated in Fig. 1e. This result indicated that FeSiAl/SR had inherent properties of ferromagnetic materials, such as high permeability, low remnant magnetization and low

coercivity. In addition, a comparison of the characteristics of the FeSiAl/SR ferroelastomers with different proportions of FeSiAl particles was performed, including the surface

morphologies of pure FeSiAl particles and FeSiAl/SR ferroelastomers with 25 wt%, 50 wt%, and 75 wt% proportions of FeSiAl particles, as shown in Fig. S1 of the supplementary file, and the

magnetic hysteresis loops of the FeSiAl/SR ferroelastomers with 25 wt%, 50 wt%, and 75 wt% proportions of FeSiAl particles, as shown in Fig. S2 of the supplementary file. Figure 1f

illustrates the fabricated samples of the main discrete components of the hybrid microenergy harvester, i.e., the FeSiAl/SR ferroelastomeric substrate, 4-layer FPCB coil, hybrid SR-air

deformation layer and PM. An assembled sample of the hybrid microenergy harvester is also shown in Fig. 1g. MICROENERGY HARVESTING BASED ON THE TRIBOELECTRIC–ELECTROMAGNETIC MECHANISM

TRIBOELECTRIC–ELECTROMAGNETIC HYBRID MECHANISM Figure 2 schematically illustrates the working mechanism of the EHTE, which is a hybrid mechanism based on the coupling of triboelectric and

electromagnetic effects. Here, the working mechanism of the hybrid microenergy harvester was described in two parts of the triboelectric nanogenerator and the electromagnetic nanogenerator,

as shown in Fig. 2a, b, respectively. Initially, the triboelectric nanogenerator is in an electrostatic neutral state. When the external force placed the silicone rubber–polyimide (SR-PI)

triboelectric pair in close contact, equivalent numbers of triboelectric charges with opposite polarities were generated at the interface of the triboelectric pair due to the

triboelectrification effect. According to the triboelectric series, polyimide is much more triboelectrically positive than silicone rubber. Therefore, the silicone rubber surface is

negatively charged, and the polyimide surface is positively charged. When the external force releases, resulting in the silicone rubber leaving the polyimide surface, the internal electrical

potential is established. The unbalanced negative charges cause the accumulation of positive charges on the permanent magnet electrode due to electrostatic induction. As a result, the

accumulated charges flow from the PM electrode to the ground through an external load; and a current pulse is generated. After the completed separation of the silicone rubber and polyimide,

the device is in the electrostatic equilibrium state. As silicone rubber moves toward the polyimide again, the charges on the permanent magnet electrode are driven to flow back to the ground

via the load, and an opposite current is obtained. Therefore, during the separating and approaching cycles of the triboelectric pair, electrons are induced to flow between the PM electrode

and ground to form currents. Meanwhile, the electromagnetic nanogenerator generates currents during the removal and approaching cycles between the PM and the FPCB coil due to electromagnetic

induction. When the PM moves away from the coil, the magnetic flux crossing the FPCB coil decreases, resulting in the induced current flow in the FPCB coil. In contrast, as the PM

approaches the coil, the magnetic flux crossing the coil increases, thereby inducing an opposite current in the FPCB coil. As a result, the hybrid microenergy harvester can convert

mechanical input into triboelectric and electromagnetic outputs simultaneously according to the hybrid mechanism of triboelectrification and electromagnetism. TRIBOELECTRIC AND

ELECTROMAGNETIC OUTPUTS To provide a stable and controllable compression force with a designable frequency and strength for the hybrid microenergy harvester, a vibration platform consisting

of a signal generating system, an amplifier and a shaker was used to help measure the electrical outputs of the hybrid microenergy harvester, as shown in supplementary Video S1. Figure 3

shows the electrical outputs of the individual parts of the proposed hybrid microenergy harvester (i.e., the triboelectric nanogenerator and the electromagnetic nanogenerator) under

continuous forces (~35.4 N) with a fixed frequency of 6 Hz from the vibration platform. The peak output voltage and the peak output current of the triboelectric nanogenerator were ~280 V and

0.32 mA, as depicted in Fig. 3a, b, respectively. Additionally, the peak output voltage and peak output current of the electromagnetic nanogenerator were ~72 mV and 3.6 mA, respectively, as

shown in Fig. 3c, d, respectively. These results indicated that the triboelectric and electromagnetic outputs of the hybrid microenergy harvester were basically consistent with the inherent

output properties of TENGs and EMGs; i.e., the TENG of EHTE possessed a relatively high output voltage but low output current, and the EMG of EHTE had a relatively high output current but

low output voltage. Thus, we used the triboelectric voltage and the electromagnetic current as the main parameters to further evaluate the electrical output characteristics of the proposed

EHTE. The output power was evaluated by connecting the individual parts of EHTE with external loading resistors. Herein, we connected a triboelectric nanogenerator with external loading

resistors with values of 1 to 100 MΩ in parallel to measure the output peak voltage of the resistor and thereby its instantaneous output power. The output peak power of the triboelectric

nanogenerator is shown in Fig. 3e. The triboelectric nanogenerator had a high internal resistance of ~30 MΩ, at which the maximum output peak power reached 235.2 μW. Meanwhile, the output

power of the electromagnetic nanogenerator was obtained by connecting the electromagnetic nanogenerator with loading resistors with various values of 1 to 300 Ω in series. The internal

resistance of the electromagnetic nanogenerator was estimated to be ~45 Ω, at which the output peak power was 93.1 μW, as shown in Fig. 3f. The area of the device was 28 × 28 mm; thus, the

instantaneous power density of the triboelectric nanogenerator and the electromagnetic nanogenerator were calculated as 30.0 and 11.9 μW/cm2, respectively. Furthermore, fatigue tests of the

EHTE were performed, as shown in Fig. S3 of the Supplementary File. After 10,800 working cycles, both the triboelectric nanogenerator and the electromagnetic nanogenerator maintained

remarkable electrical outputs. The electromagnetic nanogenerator almost retained the initial output, and the 20% output decline of the triboelectric nanogenerator could be explained by the

abrasion of the silicone rubber triboelectric layer after thousands of working cycles. Notably, the electrical output presented in Fig. 3 is the output of the hybrid microenergy harvester

using a ferroelastomer substrate with a 50% proportion of FeSiAl particles, which is the optimal proportion to obtain a higher output. Herein, the effect of the proportion of FeSiAl

particles in the FeSiAl/SR ferroelastomeric substrate on the triboelectric and electromagnetic outputs was studied, and the triboelectric peak-to-peak output voltage and the electromagnetic

peak-to-peak output current of EHTE with a ferroelastomeric substrate using varying concentrations of FeSiAl particles in silicone rubber are presented in Fig. S4. As the proportion of the

FeSiAl particles increased from 0 to 50 wt%, the triboelectric peak-to-peak voltage of the device gradually increased from 368 V to 488 V, and the electromagnetic peak-to-peak current

increased from 4.16 mA to 6.16 mA. As the FeSiAl proportion further increased to 75 wt%, the triboelectric peak-to-peak voltage increased to 544 V, but the electromagnetic peak-to-peak

current declined to 5.6 mA. As a result, we chose the ferroelastomer with a 50 wt% proportion of FeSiAl particles as the ferroelastomeric substrate. Compared with the pure silicone rubber

substrate-based hybrid microenergy harvester, the triboelectric peak-to-peak output voltage and the electromagnetic peak-to-peak output current of the FeSiAl/silicone rubber (50 wt% FeSiAl)

substrate-based device increased by ~32.6% and 48.1%, respectively, indicating the importance of the ferroelastomeric substrate in the enhancement of the electrical output of the devices.

EFFECT OF THE EXCITATION FREQUENCY ON TRIBOELECTRIC AND ELECTROMAGNETIC OUTPUTS The reliance of triboelectric and electromagnetic outputs on the frequency of the external excitation was also

studied, as illustrated in Fig. 4. The triboelectric voltage output and the electromagnetic current output of the hybrid microenergy harvester at different frequencies are shown in Fig. 4a,

b, respectively. When the frequency increased from 1 to 12 Hz with an increasing step of 1 Hz, the triboelectric voltage gradually increased from 44 to 392 V, and the electromagnetic

current increased from 0.52 to 7.00 mA. However, with a frequency increase greater than 12 Hz (i.e., 13 and 14 Hz), the triboelectric voltage output declined to 212 V, and the

electromagnetic current outputs were maintained at 7.00 mA, but its negative peak current gradually declined. The declining trend could be explained by the under-recover effect of the hybrid

microenergy harvester since the excessively short time span of the applied force did not allow it to recover to the original status completely. It is noted that the values of the

triboelectric and electromagnetic outputs were the average values of the positive peaks of the waveforms. In this case, the correlation curves of the triboelectric voltage output and the

electromagnetic current output to the frequency of the external excitation are presented in Fig. 4c, d, respectively. The electromagnetic current output was almost linear to the applied

frequency of the external excitation in the range of 1–10 Hz, demonstrating the potential of the EHTE for active frequency sensing. EHTE SERVES AS A POWER SOURCE FOR MICROELECTRONICS

POWERING The remarkable electrical outputs of the elastic hybrid triboelectric–electromagnetic microenergy harvester provide the feasibility of the device to be used as a power source for

microelectronics powering. As illustrated in Fig. 5a, the triboelectric nanogenerator of the hybrid microenergy harvester could be used to directly drive an LED screen, owing to its high

voltage property. With the help of a rectifier circuit and an energy storage capacitor, the electromagnetic nanogenerator could successfully light up the LED screen in both the noncontact

working state and the contacted working state, as shown in Fig. 5b<i>, <ii>, respectively. It is noted that the working state of the electromagnetic nanogenerator was controlled

by setting the amplitude of the external excitation from the vibration platform. More details about the effect of the amplitude of the external excitation on electromagnetic output are shown

in Fig. S5 of the supplementary file. Herein, a 1 μF-capacitor was charged for 360 s by the electromagnetic nanogenerator of the EHTE working in the noncontact state and contacted state,

and then the stored energy was used to power the LED screen. The former can make the LED screen display normally for 25 s and then gradually darken and disappear after 40 s. The latter can

make the display work normally for ~40 s and then gradually darken and disappear after 62 s. Moreover, to enhance the power delivery efficiency of the TENG, a power management circuit (PMM)

developed in a previous study9 by our group was used to improve the tremendous impedance mismatch between the triboelectric nanogenerator and the energy storage unit. Figure 5c schematically

illustrates the charging circuit of the hybrid microenergy harvester, and more detail about the PMM is schematically illustrated in Fig. S6. Herein, the charging ability of the

electromagnetic nanogenerator (EMG), the triboelectric nanogenerator only (TENG), the TENG with a power management circuit (TENG@PMM), and the hybrid nanogenerator (TENG@PMM + EMG) to an

external capacitor with a value of 10 μF was studied. As shown in Fig. 5d, within a charging time of 110 seconds, the external capacitor can be charged to 0.96 and 1.00 V by the TENG only

(i.e., the black curve) and EMG only (i.e., the green curve), respectively. With the help of the PMM, the output voltage of the charged capacitor increased to 3.52 V under the same

conditions by TENG@PMM (i.e., the blue curve). The output voltage of the charged capacitor was further enhanced to 5 V by TENG@PMM + EMG (i.e., the red curve) resulting from the hybrid

effect of the triboelectric and electromagnetic outputs, which indicates that the charging ability of the proposed hybrid microenergy harvester is remarkable. As shown in Fig. 5e, the

developed EHTE could take 255 s to charge the 10 μF-capacitor to 10 V, and it was successfully demonstrated to drive a commercial calculator, as shown in the inset view of Fig. 5e, which

reveals the feasibility of the EHTE for wearable microelectronics powering. INDUCTIVE SENSING BASED ON THE EDDY CURRENT EFFECT Inspired by the configuration of the eddy current sensor

composed of two essential parts of the sensing coil and conductive target, the assembly of the conductive permanent magnet (PM) and 4-layer FPCB coil in the electromagnetic nanogenerator of

the EHTE demonstrates the feasibility of inductive sensing realized by the eddy current effect. Herein, the conductive PM is regarded as the sensing target of the inductive sensor, and the

4-layer FPCB coil is regarded as its sensing coil. Figure 6a schematically illustrates the sensing mechanism of the inductive sensor. When the sensing coil (i.e., 4-layer FPCB coil) is

excited by an alternative current (AC), the coil generates an alternative magnetic field, which induces eddy currents in the nearby conductive sensing target (i.e., PM) due to the eddy

current effect. The induced eddy currents on the surface of the sensing target generate a magnetic field in a direction opposite to the magnetic field generated by the sensing coil, which

reduces the magnetic flux crossing the sensing coil and thereby the effective inductance of the sensing coil due to the magnetic field coupling between the sensing coil and target. In

addition, the resistance of the sensing coil increases due to the energy dissipation of the eddy currents. The induced eddy currents are affected by the distance between the sensing target

and coil. Therefore, when the compression force moves the sensing target (i.e., PM) toward the sensing coil (i.e., FPCB coil), the induced eddy currents increase so that the magnetic field

coupling between the sensing coil and the sensing target increases and the effective inductance of the sensing coil decreases. Thus, the sensing performance of the inductive sensor could be

qualitatively evaluated by the inductance response behavior of the FPCB coil to the external compression force. Herein, an inductance measurement system was built to obtain the inductance

changes in the sensing coil (i.e., FPCB coil), including the hybrid microenergy harvester at which the FPCB coil (the coil was equivalent to an LR series circuit) was connected with an

external capacitor in parallel to form an LC oscillator for inductance measurements, a signal processing circuit and a PC terminal, as shown in Fig. 6b. The signal processing circuit was

mainly comprised of an inductance-to-digital converter and an Arduino microcontroller, and more details about the signal processing circuit are given in Fig. S7 of the supplementary file.

The inductance-to-digital converter was used to drive the LC network and measure its oscillating frequency and thereby the effective inductance of the FPCB coil, according to the correlation

of the oscillating frequency and the inductance of the LC network, i.e., \(f = \frac{1}{{2\pi \sqrt {{\mathrm{LC}}} }}\), where _f_ is the oscillating frequency of the LC network, _L_ is

the inductance of the FPCB coil, and _C_ is the external capacitance. The FPCB coil on the hybrid microenergy harvester had an inductance value of 78.84 μH; therefore, we chose a 330 pF

capacitor to form the LC oscillator with an oscillating frequency of ~0.98 MHz, which was in the measurable frequency range of the inductance-to-digital converter (1 kHz ~ 10 MHz). When the

FPCB coil was driven by an AC current at the oscillating frequency of the LC network, the inductance output was rendered by the inductance-to-digital converter and sent to the Arduino

controller via the I2C protocol, which was finally displayed on a PC terminal in real-time. Figure 6c schematically illustrates the working process of the hybrid microenergy harvester

serving as an inductive sensor, which includes two stages: the (i–ii) noncontact stage and the (ii–iii) contacted stage. This behavior was mainly caused by the structural characteristics of

the hybrid deformation layer of the hybrid microenergy harvester so that the air layer of the deformation layer was first deformed (Fig. 6c(i–ii)) and then deformed in the elastomeric layers

in the whole device (Fig. 6c(ii–iii)), including the silicone rubber layer and the ferroelastomeric layer. Herein, a push-and-pull tester was used to provide the external force to the

device and display the device deformation simultaneously. Figure 6d illustrates the inductance response of the FPCB coil versus the external force (i.e., blue curve) and the whole

deformation of the inductive sensor versus the external force (i.e., black curve). The initial inductance of the integrated FPCB coil was ~95 μH. When an increasing compression force was

applied, the PM gradually moved close to the FPCB coil, and the inductance of the FPCB coil declined, with a maximum sensitivity of 0.570 N−1 in the noncontacted stage (i.e., (i–ii)) and a

sensitivity of 0.008 N−1 in the contacted stage (i.e., (i–ii)), and a degree of hysteresis (DH) of 18.2% is shown in Fig. S8 of the supplementary file. Moreover, the oscillating frequency in

the LC network versus the external force is given in Fig. S9 of the supplementary file. Figure 6e shows the inductance response behavior of the coil under seven continuous cycles of the

compression–release process, which indicated a dynamic stability of the device. To study the anti-fatigue ability of the inductive sensor, we also studied the inductance outputs of the

device under ten thousand cyclic compression–release cycles using the vibration platform to provide long-term stable and controllable forces. Figure S10 shows that the inductive sensor can

maintain stable inductance changes under 10400 working cycles and indicates that the repeatability of the sensor is outstanding. The short-term and long-term stability of the sensor was also

studied in this case. After standing for 1 day and 9 months, only 5.2% and 3.2% fluctuation existed, respectively, as shown in Fig. S11, showing outstanding short-term and long-term

stability. Moreover, the effect of the frequency of the external force on the inductance changes was investigated in this section. As depicted in Fig. 6f, the relative inductance change in

the FPCB coil can be maintained at 31.3% as the frequency of the external force increases from 1 to 8 Hz. When the frequency further increased from 8 to 14 Hz, an increasing trend of the

relative inductance change was presented. This can be explained by the large inertia force from the shaker of the vibration platform under a relatively high frequency, resulting in an

enlarged deformation of the device. The results indicated that the inductance changes in the FPCB coil have no effect on the frequency of the external force. It is worth mentioning that the

inductance increment exists for each working cycle of Fig. 6e, f, which is due to the high viscoelasticity of the silicone rubber encapsulation layer. As a result, the device cannot be

separated from the head supplying the external force immediately when the device recovers to the initial state, as shown in Fig. 6c(i), but it moves upward with the head for a moment,

resulting in an increase in the distance between the sensing target and the sensing coil, thereby increasing the effective inductance of the sensing coil. In addition, we studied the

inductive sensing performance of the device with different materials. The details about them are given in Fig. S12 of the supplementary file. Herein, we tested the relative inductance

changes in the device to the external press from different material-based objects, including the press of a glass beaker with 20 g water, the vibration of the aluminum block, the finger

press, and the press of plastics, with average relative inductance changes of 0.78%, 29.2%, 30.1%, and 60.6%, respectively. CONCLUSION In summary, an elastic hybrid

triboelectric–electromagnetic microenergy harvester (EHTE) was developed, which consisted of an FeSiAl/SR ferroelastomer substrate, a 4-layer FPCB coil, an SR-air hybrid deformation layer,

and a PM and an SR encapsulation layer. This new device was demonstrated to successfully achieve the integration of hybrid microenergy and sensing in a single device for compact active

microsystems. Based on the triboelectric–electromagnetic hybrid mechanism, the EHTE can generate triboelectric and electromagnetic outputs simultaneously from one mechanical input, with a

triboelectric output voltage, current and power density of 280 V, 0.32 mA, and 30.0 μW/cm2, respectively, and electromagnetic output voltage, current and power density of 72 mV, 3.6 mA, and

11.9 μW/cm2, respectively. The triboelectric and electromagnetic outputs were demonstrated to power microelectronics, such as LED display screens. Moreover, the hybrid output exhibited an

enhanced output power, which is large enough to power wearable microelectronics such as commercial calculators. For hybrid sensing, EHTE was proven to achieve both active frequency sensing

and passive inductive sensing based on electromagnetic induction. Specifically, the electromagnetic nanogenerator was verified to linearly sense the frequency of the external excitation in

the frequency range of 1~10 Hz. Moreover, based on the eddy current effect, the proposed EHTE can be used as an inductive sensor for passive sensing according to the quantitative relation

between the inductance change in the sensing coil (i.e., FPCB coil) and the external force. Therefore, the developed EHTE successfully achieved the integration of hybrid microenergy, active

frequency sensing and passive inductive sensing in a compact form, which provides promising potential for wearable electronic and active microsystem applications. METHODS FABRICATION OF THE

DEVELOPED EHTE Figure 7 schematically illustrates the fabrication process flow of the developed elastic hybrid triboelectric–electromagnetic microenergy harvester (EHTE), including six main

steps. First, the liquid ferroelastomer was prepared by mixing FeSiAl particles (diameter: 4 –20 μm) and liquid silicone rubber (SR, Ecoflex 00-30) at a weight ratio of 1:1. Then, the liquid

ferroelastomer (FeSiAl/SR) was dispersed atop a prepared 3D printing mold with a cuboid pattern (i.e., mold 1), followed by vacuum defoaming to remove bubbles in the liquid ferroelastomer

and at the interface between mold 1 and the liquid ferroelastomer. Second, a 4-layer FPCB coil was gently placed on the surface of the obtained liquid ferroelastomer. After vacuum defoaming

and curing at room temperature successively, the FPCB coil can be successfully embedded on the surface of the FeSiAl/SR ferroelastomeric substrate. The ferroelastomeric substrate embedded

with the FPCB coil was obtained by peeling it off mold 1. Third, some liquid silicone rubber was successively dropped into the other 3D-printed mold (i.e., mold 2), followed by vacuum

defoaming and room temperature curing. The designed silicone rubber–air hybrid deformation layer was obtained by replicating it from mold 2. Fourth, the obtained deformation layer was bonded

with the ferroelastomeric substrate with an embedded FPCB coil by dispersing a thin layer of liquid silicone rubber at their interface. Fifth, after curing the liquid silicone rubber at

room temperature, a conductive permanent magnet (PM, with a thickness of 2 mm and diameter of 20 mm) was placed in the top round groove of the deformation layer and was encapsulated by

liquid silicone rubber. Finally, the hybrid microenergy harvester was fabricated by curing the liquid silicone rubber at room temperature. It is noted that the liquid silicone rubber used in

the whole process was prepared by mixing Part A and Part B of the silicone rubber solution (Ecoflex 00-30) at a weight ratio of 1:1. TESTS AND MEASUREMENTS The surface morphologies of the

FeSiAl/SR ferroelastomer were characterized using scanning electron microscopy (SEM, JSM-6490LV, JEOL Ltd.). The magnetic hysteresis loops of the FeSiAl/SR ferroelastomer were tested by a

vibrating sample magnetometer (8600 Series VSM, Lake Shore CRYOTRONICS). A vibration platform consisting of a signal generating system (33250A, Agilent), an amplifier and a shaker was used

to provide a stable and controllable force with designable frequency to the device. The triboelectric voltage outputs were measured using a digital oscilloscope (DS2302A, RIOGL) with a 100

MΩ probe, and the triboelectric current outputs were measured by a low-noise current preamplifier (SR570, Stanford Research Systems) and a digital oscilloscope (DS2302A, RIOGL) with a 100 MΩ

probe. The electromagnetic outputs were measured using an electrometer (6514, KEITHLEY) and a digital oscilloscope (DS2302A, RIOGL) with a 1 MΩ probe. The charging curves of the device were

tested by a digital oscilloscope (DS2302A, RIOGL) with a 100 MΩ probe. The external force applied by the vibration platform was tested by a commercial force sensor connected to a force

gauge (HP-160, HANDPI). REFERENCES * Serror, M., Hack, S., Henze, M., Schuba, M. & Wehrle, K. Challenges and opportunities in securing the industrial internet of things. _IEEE Trans.

Ind. Inf._ 17, 2985–2996 (2021). Article Google Scholar * Li, Z., Liu, Y., Liu, A., Wang, S. & Liu, H. Minimizing convergecast time and energy consumption in green internet of things.

_IEEE T. Emerg. Top. Com._ 8, 797–813 (2020). Google Scholar * Claro, M. S., Stroppa, D. G., da Silva, E. C. F. & Quivy, A. A. Strong photovoltaic effect in high-density InAlAs and

InAs/InAlAsquantum-dot in frared photodetectors. _Sens. Actuators A_ 315, 112262 (2020). Article Google Scholar * He, Q. et al. Surface passivation of perovskite thin films by phosphonium

halides for efficient and stable solar cells. _J. Mater. Chem. A_ 8, 2039 (2020). Article Google Scholar * Wei, X., Peng, Y., Jing, G., Simon, T. & Cui, T. High-performance perovskite

solar cells fabricated by a hybrid physical-chemical vapor deposition. _J. Sol. Energy Eng._ 143, 041006 (2021). Article Google Scholar * Bell, L. E. Cooling, heating, generating power,

and recovering waste. _Heat. Thermoelectr. Syst. Sci._ 321, 1457–1461 (2008). Google Scholar * Liu, L. et al. A photovoltaic self-powered gas sensor based on a single-walled carbon

nanotube/Si heterojunction. _Nanoscale_ 9, 18579–18583 (2017). Article Google Scholar * Wen, D. L. et al. Wearable multi-sensing double-chain thermoelectric generator. _Microsyst.

Nanoeng._ 6, 68 (2020). Article Google Scholar * Maharjan, P. et al. High-performance cycloid inspired wearable electromagnetic energy, harvester for scavenging human motion energy. _Appl.

Energy_ 256, 113987 (2019). Article Google Scholar * Beeby, S. P. et al. A micro electromagnetic generator for vibration energy harvesting. _J. Micromech. Microeng._ 17, 1257–1265 (2007).

Article Google Scholar * Annapureddy, V. et al. Magnetic energy harvesting with magnetoelectrics: an emerging technology for self-powered autonomous systems. _Sustain. Energy Fuels_ 1,

2039 (2017). Article Google Scholar * Hu, D. et al. Strategies to achieve high performance piezoelectric nanogenerators. _Nano Energy_ 55, 288–304 (2019). Article Google Scholar * Lee,

E. J. et al. High-performance piezoelectric nanogenerators based on chemically-reinforced composites. _Energy Environ. Sci._ 11, 1425 (2018). Article Google Scholar * Zhou, D. et al. A

piezoelectric nanogenerator promotes highly stretchable and self-chargeable supercapacitors. _Mater. Horiz._ 7, 2158 (2020). Article Google Scholar * Fan, F. R., Tian, Z. Q. & Wang, Z.

L. Flexible triboelectric generator. _Nano Energy_ 1, 328–334 (2012). Article Google Scholar * Long, L. et al. High performance floating self-excited sliding triboelectric nanogenerator

for micro mechanical energy harvesting. _Nat. Commun._ 12, 4689 (2021). Article Google Scholar * Hu, Y., Luo, A., Wang, J. & Wang, F. Voltage regulation and power management for

wireless flow sensor node self-powered by energy harvester with enhanced reliability. _IEEE Access_ 7, 154836–154843 (2019). Article Google Scholar * Wang, H., Han, M., Song, Y. &

Zhang, H. Design, manufacturing and applications of wearable triboelectric nanogenerators. _Nano Energy_ 81, 105627 (2021). Article Google Scholar * Fu, X. et al.

Breeze-wind-energy-powered autonomous wireless anemometer based on rolling contact-electrification. _ACS Energy Lett._ 6, 2343–2350 (2021). Article Google Scholar * Liu, G., Chen, T., Xu,

J. & Wang, K. Blue energy harvesting on nanostructured carbon materials. _J. Mater. Chem. A_ 6, 18357 (2018). Article Google Scholar * Xu, C., Song, Y., Han, M. & Zhang, H.

Portable and wearable self-powered systems based on emerging energy harvesting technology. _Microsyst. Nanoeng._ 7, 25 (2021). Article Google Scholar * Son, E. J., Kim, J. H., Kim, K.

& Park, C. B. Quinone and its derivatives for energy harvesting and storage materials. _J. Mater. Chem. A_ 4, 11179 (2016). Article Google Scholar * Miao, L. et al. 3D

temporary-magnetized soft robotic structures for enhanced energy harvesting. _Adv. Mater._ 33, 2102691 (2021). Article Google Scholar * Zhang, X. S. et al. All-in-one self-powered flexible

microsystems based on triboelectric nanogenerators. _Nano Energy_ 47, 410–426 (2018). Article Google Scholar * Wang, Z. L. Triboelectric nanogenerators as new energy technology for

self-powered systems and as active mechanical and chemical sensors. _ACS Nano_ 7, 9533–9557 (2013). Article Google Scholar * Tang, W. et al. Liquid-metal electrode for high-performance

triboelectric nanogenerator at an instantaneous energy conversion efficiency of 70.6%. _Adv. Funct. Mater._ 25, 3718–3725 (2015). Article Google Scholar * Wen, D. L. et al. Printed

silk-fibroin-based triboelectric nanogenerators for multi-functional wearable sensing. _Nano Energy_ 66, 104123 (2019). Article Google Scholar * Xu, C. et al. Raindrop energy-powered

autonomous wireless hyetometer based on liquid-solid contact electrification. _Microsyst. Nanoeng._ 8, 30 (2022). Article Google Scholar * Liu, Z., Zhao, Z., Zeng, X., Fu, X. & Hu, Y.

Expandable microsphere-based triboelectric nanogenerators as ultrasensitive pressure sensors for respiratory and pulse monitoring. _Nano Energy_ 59, 295–301 (2019). Article Google Scholar

* Song, Y., Mukasa, D., Zhang, H. & Gao, W. Self-powered wearable biosensors. _Acc. Mater. Res_. 2, 184–197 (2021). Article Google Scholar * Deng, H. T. et al. Super-stretchable

multi-sensing triboelectric nanogenerator based on liquid conductive composite. _Nano Energy_ 83, 105823 (2021). Article Google Scholar * Ryu, H., Yoon, H. J. & Kim, S. W. Hybrid

energy harvesters: toward sustainable energy harvesting. _Adv. Mater._ 31, 1802898 (2019). Article Google Scholar * Sharov, V. A. et al. InP/Si heterostructure for high-current hybrid

triboelectric/photovoltaic generation. _ACS Appl. Energy Mater._ 2, 4395–4401 (2019). Article Google Scholar * Jung, S. et al. 3D Cu ball-based hybrid triboelectric nanogenerator with

non-fullerene organic photovoltaic cells for self-powering indoor electronics. _Nano Energy_ 77, 105271 (2020). Article Google Scholar * Su, L. et al. Photoinduced enhancement of a

triboelectric nanogenerator based on an organolead halide perovskite. _J. Mater. Chem. C._ 4, 10395 (2016). Article Google Scholar * Guo, Y. et al. All-fiber hybrid piezoelectric-enhanced

triboelectric nanogenerator for wearable gesture monitoring. _Nano Energy_ 48, 152–160 (2018). Article Google Scholar * Li, M. et al. All-in-one cellulose based hybrid tribo/piezoelectric

nanogenerator. _Nano Res_. 12, 1831–1835 (2019). Article Google Scholar * Chen, X. et al. A wave-shaped hybrid piezoelectric and triboelectric nanogenerator based on P(VDF-TrFE)

nanofibers. _Nanoscale_ 9, 1263 (2017). Article Google Scholar * Shao, H. et al. Triboelectric-electromagnetic hybrid generator for harvesting blue. _Energy Nano-Micro Lett._ 10, 54

(2018). Article Google Scholar * Han, Q. et al. Hybrid triboelectric-electromagnetic generator for self-powered wind speed and direction detection. _Sustain. Energy Technol. Assess._ 39,

100717 (2020). Google Scholar * Chen, Y. L., Liu, D., Wang, S., Li, Y. F. & Zhang, X. S. Self-powered smart active RFID tag integrated with wearable hybrid nanogenerator. _Nano Energy_

64, 103911 (2019). Article Google Scholar * Wan, J. et al. A flexible hybridized electromagnetic-triboelectric nanogenerator and its application for 3D trajectory sensing. _Nano Energy_

74, 104878 (2020). Article Google Scholar * Wang, P. et al. Complementary electromagnetic-triboelectric active sensor for detecting multiple mechanical triggering. _Adv. Funct. Mater._ 28,

1705808 (2018). Article Google Scholar * Wang, S., Wang, Z. L. & Yang, Y. A one-structure-based hybridized nanogenerator for scavenging mechanical and thermal energies by

triboelectric-piezoelectric-pyroelectric effects. _Adv. Mater._ 28, 2881–2887 (2016). Article Google Scholar * He, J. et al. Triboelectric-piezoelectric-electromagnetic hybrid

nanogenerator for high efficient vibration energy harvesting and self-powered wireless monitoring system. _Nano Energy_ 43, 326–339 (2018). Article Google Scholar * Wang, H. & Feng, Z.

Ultrastable and highly sensitive eddy current displacement sensor using self-temperature compensation. _Sens. Actuators A_ 203, 362–368 (2013). Article Google Scholar * Wang, H. et al.

Robust and high-performance soft inductive tactile sensors based on the eddy-current effect. _Sens. Actuators A_ 271, 44–52 (2018). Article Google Scholar Download references

ACKNOWLEDGEMENTS This work is financially supported by the National Natural Science Foundation of China (No. 62074029, No. 61905035, No. 61971108, No. 62004029, No. 51905554), the Key

R&D Program of Sichuan Province (No. 2022JDTD0020, No. 2022YFG0163, No. 2020ZHCG0038), the Sichuan Science and Technology Program (No. 2020YJ0015), and the Fundamental Research Funds for

the Central Universities (No. ZYGX2019Z002). AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * School of Electronic Science and Engineering, University of Electronic Science and Technology of

China, 611731, Chengdu, China Hai-Tao Deng, Zhi-Yong Wang, Yi-Lin Wang, Dan-Liang Wen & Xiao-Sheng Zhang Authors * Hai-Tao Deng View author publications You can also search for this

author inPubMed Google Scholar * Zhi-Yong Wang View author publications You can also search for this author inPubMed Google Scholar * Yi-Lin Wang View author publications You can also search

for this author inPubMed Google Scholar * Dan-Liang Wen View author publications You can also search for this author inPubMed Google Scholar * Xiao-Sheng Zhang View author publications You

can also search for this author inPubMed Google Scholar CONTRIBUTIONS H.-T.D. conceived the research, designed and carried out the experiments, and prepared the paper. Z.-Y.W. and Y.-L.W.

prepared the figures and the paper, and provided support for the experiments. D.-L.W. provided support for the tests and analysis. X.-S.Z. conceived the research, supervised the experiments

and analysis, and prepared the paper. CORRESPONDING AUTHOR Correspondence to Xiao-Sheng Zhang. ETHICS DECLARATIONS CONFLICT OF INTEREST The authors declare no competing interests.

SUPPLEMENTARY INFORMATION SUPPLEMENTARY FILE SUPPLEMENTARY INFORMATION VIDEO RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a Creative Commons Attribution 4.0

International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the

source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative

Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by

statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit

http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Deng, HT., Wang, ZY., Wang, YL. _et al._ Integrated hybrid sensing and microenergy

for compact active microsystems. _Microsyst Nanoeng_ 8, 61 (2022). https://doi.org/10.1038/s41378-022-00393-z Download citation * Received: 24 February 2022 * Revised: 14 April 2022 *

Accepted: 29 April 2022 * Published: 06 June 2022 * DOI: https://doi.org/10.1038/s41378-022-00393-z SHARE THIS ARTICLE Anyone you share the following link with will be able to read this

content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative