Play all audios:

ABSTRACT Hollow micro/nanolattices have emerged in recent years as a premium solution compared to conventional foams or aerogels for mechanically robust lightweight structures. However,

existing hollow metallic micro/nanolattices often cannot exhibit high toughness due to the intrinsic brittleness from localized strut fractures, limiting their broad applications. Here, we

report the development of hollow CoCrNi medium-entropy alloy (MEA) nanolattices, which exhibit high specific energy absorption (up to 25 J g−1) and resilience (over 90% recoverability) by

leveraging size-induced ductility and rationally engineered MEA microstructural defects. This strategy provides a pathway for the development of ultralight, damage-resistant metallic

metamaterials for a myriad of structural and functional applications. SIMILAR CONTENT BEING VIEWED BY OTHERS MANUFACTURE-FRIENDLY NANOSTRUCTURED METALS STABILIZED BY DUAL-PHASE HONEYCOMB

SHELL Article Open access 19 April 2022 STRONG YET DUCTILE NANOLAMELLAR HIGH-ENTROPY ALLOYS BY ADDITIVE MANUFACTURING Article 03 August 2022 AN ORDER-DISORDER CORE-SHELL STRATEGY FOR

ENHANCED WORK-HARDENING CAPABILITY AND DUCTILITY IN NANOSTRUCTURED ALLOYS Article Open access 09 August 2024 INTRODUCTION In the past decade, micro/nanoarchitected materials have proven

their potential to overcome canonical couplings between mechanical properties (e.g., strength–density) through the combined benefits of rationally designed cellular topology and size

effects1,2,3,4,5,6,7,8,9,10,11. Compared to stochastic cellular materials, the ordered and periodic arrangement of internal pores allows micro/nanolattices to exhibit superior mechanical

properties, while bringing the dimensions of a material down to the submicron length scale could unlock unique properties that are generally lost in bulk materials8,9,10,11. In particular,

hollow micro/nanolattices provide the only solution to obtain extremely lightweight materials while simultaneously allowing for high recoverability and specific strength to be achieved.

These properties are attributed to the multistage weight reduction resulting from the hollow strut cellular topology as well as the prominence of the size effect in influencing the

mechanical properties and behavior of nanoscale materials. Among these materials, hollow metallic lattices possess immense potential to achieve simultaneous high strength and ductility1,2,3.

Unfortunately, despite their high strength/stiffness, existing hollow metallic lattices possess low toughness, and the inherently brittle nature of their constituents induces catastrophic

or localized fractures in high-stress regions (i.e., nodes). This phenomenon has also consistently been observed in other reported solid or core-shell lattices, which is detrimental for

practical applications because it significantly degrades their mechanical robustness6,12,13,14. Recently, owing to their tunable composition and unique microstructures15,16,17,18, the

incorporation of multicomponent alloys, such as high- and medium-entropy alloys (HEAs/MEAs) with micro/nanolattices, into a composite configuration19,20,21 has been proposed, and their

potential superiority over conventional metals/alloys in terms of their tunable mechanical (and functional) properties has been demonstrated. Nevertheless, the creation of pure HEA/MEA

lattices with hollow struts has never been reported and is challenging but crucial to fully harness their potential for engineering applications (for instance, under extreme temperature

environments at high/low temperatures22,23,24 or to provide an enhanced surface-to-volume ratio in catalysis25,26). Herein, we fabricated, for the first time, hollow CoCrNi MEA nanolattices

that can exhibit ultrahigh energy absorption and resilience upon repeated loading due to the induced damage resistance derived from the strong and ductile nanostructured MEA film. Combining

the benefits of hollow nanoarchitectures with the vast compositional space of HEAs/MEAs presents a new route for the development of lightweight, mechanically robust, and versatile

nanoarchitected metamaterials for structural and functional applications25,26,27. MATERIALS AND METHODS FABRICATION OF HOLLOW MEA NANOLATTICES Stretching-dominated octet lattices were

synthesized by employing an additive manufacturing technique based on two-photon lithography (Nanoscribe GmbH). The polymer lattices were fabricated using an acrylate-based UV photosensitive

resin (IP-L 780). DC magnetron sputtering was subsequently used to conformally coat a thin MEA film onto the polymer scaffold at 5 × 10−6 Pa. The argon flow for ignition was set to 10

standard cubic centimeters per minute (sccm), while the total argon flow rate was fixed at 10 sccm for 120 s. The DC power used was 350 W, and the substrate was rotated at a rate of 30

r.p.m. min−1 to ensure uniform film deposition. Subsequently, the internal polymer core of the MEA-coated nanolattice was exposed via focused ion beam (FIB) milling and removed via plasma

ashing (Diener Zepto) for 12 h at 100 W. MICROSTRUCTURAL AND COMPOSITIONAL CHARACTERIZATION The film thickness, microstructure, and composition of the nanolattices and reference MEA film

were observed by using field emission scanning electron microscopy (FESEM, FEI Quanta FEG450) equipped with energy dispersive X-ray spectroscopy (EDX, Oxford), as well as transmission

electron microscopy (TEM, JEOL JEM 2100) equipped with selected area electron diffraction (SAED), where the TEM samples were prepared via ion milling with liquid nitrogen cooling to prevent

microstructural changes such as phase transitions. The grain sizes and atomic distribution in the MEA film were investigated via FIB (FEI Scios DualBeam) milling and 3D atomic probe

tomography (APT, LEAP 5000XR). IN SITU MECHANICAL TESTING The experimental setup for the in situ uniaxial compression tests on the MEA hollow nanolattices, which were performed at room

temperature, included a Hysitron PI85 SEM Picoindenter (Bruker) to investigate the mechanical properties and observe the deformation behavior of the lattices. Uniaxial compression tests were

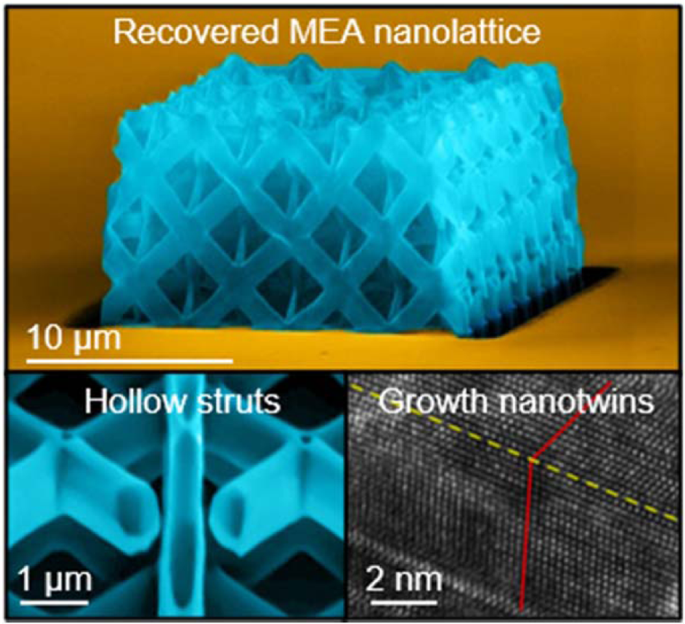

conducted on the MEA nanolattices at a prescribed strain rate of 10−3 s−1. RESULTS AND DISCUSSION HIERARCHICAL STRUCTURE The CoCrNi MEA hollow octet nanolattices were initially prepared by

fabrication of polymer nanolattice templates via two-photon lithography direct laser writing (Fig. 1a) followed by magnetron sputtering with a high deposition rate to facilitate the

deposition of MEA films with dense nanotwins and stacking faults (SFs) (Fig. 1b). The directionality of sputtering has previously led to nonuniform walls in hollow lattices, generating

additional stress concentrations that reduce their mechanical properties. Therefore, the elliptical geometry of the strut cross-section in this work was designed to optimize the uniformity

of the deposited metal film (Fig. S1). A FIB was employed to expose the polymer core inside, which was subsequently removed via plasma ashing (Fig. 1c) to ultimately produce hollow MEA

nanolattices (Fig. 1d)28. Figure 1e–h depicts the hierarchical structure of the as-fabricated hollow CoCrNi MEA nanolattice, showing critical feature sizes ranging from tens of micrometers

(whole lattice) down to hundreds of nanometers (strut size) and to a few nanometers (planar defects in metal film). Compositional analysis of the deposited MEA film showing a homogenous

elemental distribution is shown in Fig. S2. MECHANICAL TESTING Figure 2a and b shows a series of real-time images depicting the deformation behavior of a thin-walled (i.e., 30 nm) hollow

nanolattice when subjected to cyclic uniaxial compression under scanning electron microscopy (SEM), while the corresponding stress–strain curves are shown in Fig. 2c. During the initial

stage of compression (Stages I to III), the nanolattice struts mainly deform elastically until they buckle at a plateau stress. At higher compressive strains (Stages III to IV), the

nanolattices exhibit localized deformation or buckling at their nodes without any apparent fracture (Fig. 2a) or significant stress drops (Fig. 2c). In this stage, the local strain at the

nodes is typically too large for micro/nanolattices with nonductile constituents to withstand, resulting in either catastrophic brittle or localized strut fracture. In contrast, our

nanolattice has walls that are significantly more ductile, suppressing otherwise imminent strut fracture. Upon unloading (Fig. 2b), our MEA nanolattices also exhibit large recoverability

(over 90%) and exceptional resilience accentuated by the relatively marginal decrease in energy absorption per unit volume (i.e., toughness) over the course of multiple loading cycles

compared to previously reported micro/nanolattices, retaining over 60% of their initial energy in the subsequent cycle (Fig. 2d). The energy loss coefficient typically refers to the ratio of

dissipated energy to the work done during compression, which depicts the hysteresis of a material during cyclic loading21. For our MEA nanolattices, the converged energy loss coefficient is

greater than 0.8 even after four loading cycles, outperforming previously reported micro/nanolattices1,3,5,21. DEFORMATION MECHANISM The mechanical toughness and resilience of our

nanolattices are mainly attributed to the dual elastic and ductile deformation modes that occur in the low- and high-stress regions of the nanolattice, respectively (Fig. 3a–d). The

manifestation of this combined deformation mode can be ascribed to two main factors, namely, the external size effect and internal microstructure of the MEA film. The influence of the size

effect can be explained by analyzing the competing failure mechanisms for hollow lattices subjected to uniaxial compression5. The transition in deformation modes between shell buckling and

fracture can be determined by equating the stresses required to initiate each mechanism, and for elliptical strut lattices with an aspect ratio of approximately 3:1 (_a_ = 3_b_), the

following expression can be used5,29: $$\left( {\frac{t}{a}} \right)_{{\mathrm{crit}}} = \frac{{\sigma _{{\mathrm{fracture}}}}}{E}\sqrt {3\left( {1 - \nu^2} \right)}$$ where \(\left( {t/a}

\right)_{{\mathrm{crit}}}\) represents the ratio of the critical wall thickness, _t_, to the major-axis radius of the strut, _a_, at which the shell buckling-to-fracture transition occurs;

\(\sigma _{{\mathrm{fracture}}}\) is the fracture strength of the MEA film, which can be taken as \(\sigma _{{\mathrm{fracture}}} = H/3\), where _H_ is the hardness of the film determined by

nanoindentation28,30. _E_ and _ν_ represent the Young’s modulus and Poisson’s ratio of the MEA film, respectively. By using the tested (Fig. S3) and reported values for the CoCrNi film31,

_E_ = 214 GPa, _ν_ = 0.31, and \(\sigma _{{\mathrm{fracture}}}\) = 3.4 GPa, it can be deduced that \(\left( {t/a} \right)_{{\mathrm{crit}}}\) ~0.026. The _t_/_a_ ratio of the thin-walled

nanolattices is slightly smaller than the critical value (~0.025). Therefore, shell buckling, which is usually observed as wrinkling and warping of the hollow struts at the nodes, should

dominate over strut fracture. This agrees well with the deformation displayed by the thin-walled nanolattices (Fig. 2a, b), which allows large recoverability to be achieved. Increasing the

wall thickness slightly beyond the critical _t_/_a_ ratio will result in nanolattices with large plastic deformation but low recoverability. For thick-walled nanolattices whose _t_/_a_

ratios are significantly higher than the critical value, strut fracture dominates, making the nanolattices more brittle (Fig. S4). However, these equations cannot capture the influence of

stress concentration and microstructural effects, which has thus far been responsible for localized strut fracture in hollow micro/nanolattices1,5,28,32. Intriguingly, localized strut

fractures in the high-stress regions were observed to be suppressed in our thin-walled MEA nanolattices, and wrinkled nodes were manifested instead (Fig. 3c). This is mainly ascribed to the

inherent ductility of our MEA nanolattices. The intrinsic deformation mechanism of the CoCrNi MEA film was investigated via TEM. Figure 1h shows a representative TEM image of the MEA film

with a thickness of ~30 nm. The MEA grows in a nanosized (~9.0 nm) columnar grain structure with a face-centered cubic (fcc) phase populated with a high density of nanotwins and SFs. The

numerous grain boundaries and SFs serve as significant obstacles to dislocation movement, providing substantial strength by decreasing the dislocation-free pathway33. The sub-2-nm-thick

twin/SF/matrix lamellar structure of the MEA was revealed by high-resolution TEM observation (Fig. 3f). It has been reported that when the twin boundary spacing is smaller than a critical

value, the dense nanotwins in an MEA film could act as detwinning sites, allowing for large plastic deformation to occur34,35. Postmortem TEM observation of the MEA film revealed the

annihilation of twins in the severely deformed region (Fig. 3e), implying that the ample nanotwins act as detwinning sites, which allows for large plastic deformation to be achieved at the

nodes. Therefore, due to the strength and ductility of the MEA film, our thin-walled nanolattices exhibit localized plastic wrinkling in regions of high stress concentration (i.e., nodes) to

restrain fracture, while other strut regions show recoverable shell buckling, enabling simultaneous high toughness and resilience with minimal mechanical degradation. The mechanical

properties and deformation behavior of the hollow MEA nanolattices are summarized in Table S1. HIGH SPECIFIC ENERGY ABSORPTION AND RESILIENCE Owing to the high ductility of the MEA film and

dual deformation modes, our damage-resistant CoCrNi hollow nanolattices can exhibit unprecedented specific strength, energy absorption, and resilience compared to previously reported hollow

lattices (Fig. 4 and Table S2)1,2,3,5,28,32,36,37,38. From Fig. 4a, it can be seen that our thin-walled hollow CoCrNi MEA nanolattices possess superior strength (up to 20 MPa) among all the

reported hollow micro/nanolattices while retaining high recoverability (>90%). The stretching-dominated octet architecture and high hardness of the CoCrNi walls are mainly responsible for

the exceptional strength of the MEA nanolattices, while the optimized film thickness of the MEA walls allows elastic shell buckling to dominate their deformation behavior, enabling high

recoverability to be achieved. Other hollow nanolattices with comparable or higher compressive strength typically exhibit catastrophic or brittle failure at low strains. The specific

strength of our thin-walled hollow nanolattices (up to 75 MPa g−1 cm3) is also among the highest reported thus far and even higher than that of previously reported solid-beam HEA

microlattices (Fig. S5)39. The specific energy absorption (SEA) represents the energy absorption per unit volume divided by the density and is a crucial parameter in determining the

efficiency of a material as an energy absorber40. The synergy obtained by the employment of the high strength and ductile MEA film with the nanolattice architecture of optimized wall

thickness enables our MEA hollow nanolattices to achieve unsurpassed SEA with relatively marginal degradation over multiple loading cycles compared to previously reported lightweight

micro/nanolattices (Fig. 4b). In most reported hollow lattices, localized strut fracture is typically observed upon mechanical loading due to the inherently brittle nature of the

load-bearing material. Therefore, in each loading cycle, the accumulated strut fracture continually results in significant deterioration of the mechanical properties. On the other hand, our

MEA nanolattices can suppress localized strut fracture due to detwinning in high-stress regions (i.e., nodes). This ultimately enables our nanolattices to preserve more energy in subsequent

cycles. In this work, we demonstrated the fabrication of hollow MEA nanolattices that can attain ultrahigh SEA with minimal degradation over multiple loading cycles. This was achieved

through the mixed elastic–ductile deformation modes facilitated by the size-induced ductility arising from optimization of the wall thickness and judicious incorporation of dense nanotwins

into the low-SF CoCrNi MEA, which act as detwinning sites to suppress localized strut fracture. Coupled with the boundless design space of architected HEAs/MEAs, our findings provide a new

path for the creation of ultralight and damage-resistant pure metallic micro/nanolattices with unprecedented combinations of toughness and resilience for next-generation structural and

multifunctional applications. REFERENCES * Schaedler, T. A. et al. Ultralight metallic microlattices. _Science_ 334, 962–965 (2011). Article CAS Google Scholar * Zheng, X. et al.

Ultralight, ultrastiff mechanical metamaterials. _Science_ 344, 1373–1377 (2014). Article CAS Google Scholar * Zheng, X. et al. Multiscale metallic metamaterials. _Nat. Mater._ 15, 1100

(2016). Article CAS Google Scholar * Jang, D., Meza, L. R., Greer, F. & Greer, J. R. Fabrication and deformation of three-dimensional hollow ceramic nanostructures. _Nat. Mater._ 12,

893 (2013). Article CAS Google Scholar * Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. _Science_ 345, 1322–1326

(2014). Article CAS Google Scholar * Bauer, J., Schroer, A., Schwaiger, R. & Kraft, O. Approaching theoretical strength in glassy carbon nanolattices. _Nat. Mater._ 15, 438 (2016).

Article CAS Google Scholar * Zhang, X., Vyatskikh, A., Gao, H., Greer, J. R. & Li, X. Lightweight, flaw-tolerant, and ultrastrong nanoarchitected carbon. _Proc. Natl Acad. Sci. USA_

116, 6665–6672 (2019). Article CAS Google Scholar * Bauer, J. et al. Nanolattices: an emerging class of mechanical metamaterials. _Adv. Mater._ 29, 1701850 (2017). Article Google Scholar

* Surjadi, J. U. et al. Mechanical metamaterials and their engineering applications. _Adv. Eng. Mater._ 21, 1800864 (2019). Article CAS Google Scholar * Schwaiger, R., Meza, L. &

Li, X. The extreme mechanics of micro-and nanoarchitected materials. _MRS Bull._ 44, 758–765 (2019). Article Google Scholar * Zhang, X., Wang, Y., Ding, B. & Li, X. Design,

fabrication, and mechanics of 3D micro‐/nanolattices. _Small_ 16, 1902842 (2020). Article CAS Google Scholar * Bauer, J., Hengsbach, S., Tesari, I., Schwaiger, R. & Kraft, O.

High-strength cellular ceramic composites with 3D microarchitecture. _Proc. Natl Acad. Sci. USA_ 111, 2453–2458 (2014). Article CAS Google Scholar * Mieszala, M. et al. Micromechanics of

amorphous metal/polymer hybrid structures with 3D cellular architectures: size effects, buckling behavior, and energy absorption capability. _Small_ 13, 1602514 (2017). Article Google

Scholar * Eckel, Z. C. et al. Additive manufacturing of polymer-derived ceramics. _Science_ 351, 58–62 (2016). Article CAS Google Scholar * Yeh, J. W. et al. Nanostructured high‐entropy

alloys with multiple principal elements: novel alloy design concepts and outcomes. _Adv. Eng. Mater._ 6, 299–303 (2004). Article CAS Google Scholar * Cantor, B., Chang, I., Knight, P.

& Vincent, A. Microstructural development in equiatomic multicomponent alloys. _Mater. Sci. Eng. A_ 375, 213–218 (2004). Article Google Scholar * Tsai, M.-H. & Yeh, J.-W.

High-entropy alloys: a critical review. _Mater. Res. Lett._ 2, 107–123 (2014). Article Google Scholar * George, E. P., Raabe, D. & Ritchie, R. O. High-entropy alloys. _Nat. Rev.

Mater._ 4, 515–534 (2019). Article CAS Google Scholar * Gao, L. et al. High‐entropy alloy (HEA)‐coated nanolattice structures and their mechanical properties. _Adv. Eng. Mater._ 20,

1700625 (2018). Article Google Scholar * Surjadi, J. U., Gao, L., Cao, K., Fan, R. & Lu, Y. Mechanical enhancement of core-shell microlattices through high-entropy alloy coating. _Sci.

Rep._ 8, 5442 (2018). Article Google Scholar * Zhang, X. et al. Three-dimensional high-entropy alloy–polymer composite nanolattices that overcome the strength–recoverability trade-off.

_Nano Lett._ 18, 4247–4256 (2018). Article CAS Google Scholar * Senkov, O., Wilks, G., Miracle, D., Chuang, C. & Liaw, P. Refractory high-entropy alloys. _Intermetallics_ 18,

1758–1765 (2010). Article CAS Google Scholar * Gludovatz, B. et al. A fracture-resistant high-entropy alloy for cryogenic applications. _Science_ 345, 1153–1158 (2014). Article CAS

Google Scholar * Gludovatz, B. et al. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. _Nat. Commun._ 7, 10602 (2016). Article CAS Google Scholar

* Yao, Y. et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. _Science_ 359, 1489–1494 (2018). Article CAS Google Scholar * Zhang, N. et al. Lattice oxygen activation

enabled by high-valence metal sites for enhanced water oxidation. _Nat. Commun._ 11, 1–11 (2020). Google Scholar * Christensen, J., Kadic, M., Kraft, O. & Wegener, M. Vibrant times for

mechanical metamaterials. _MRS Commun._ 5, 453–462 (2015). Article CAS Google Scholar * Lee, S.-W., Jafary-Zadeh, M., Chen, D. Z., Zhang, Y.-W. & Greer, J. R. Size effect suppresses

brittle failure in hollow Cu60Zr40 metallic glass nanolattices deformed at cryogenic temperatures. _Nano Lett._ 15, 5673–5681 (2015). Article CAS Google Scholar * Allen, H. & Bulson,

P. _Background to Buckling_ (McGraw-Hill, 1980). * Oliver, W. C. & Pharr, G. M. An improved technique for determining hardness and elastic modulus using load and displacement sensing

indentation experiments. _J. Mater. Res._ 7, 1564–1583 (1992). Article CAS Google Scholar * Feng, X. et al. Heavily twinned CoCrNi medium-entropy alloy with superior strength and crack

resistance. _Mater. Sci. Eng. A_ 788, 139591 (2020). Article CAS Google Scholar * Dou, N. G., Jagt, R. A., Portela, C. M., Greer, J. R. & Minnich, A. J. Ultralow thermal conductivity

and mechanical resilience of architected nanolattices. _Nano Lett._ 18, 4755–4761 (2018). Article CAS Google Scholar * Feng, X., Surjadi, J. U., Li, X. & Lu, Y. Size dependency in

stacking fault-mediated ultrahard high-entropy alloy thin films. _J. Alloys Compd._ 844, 156187 (2020). Article CAS Google Scholar * Li, X., Wei, Y., Lu, L., Lu, K. & Gao, H.

Dislocation nucleation governed softening and maximum strength in nano-twinned metals. _Nature_ 464, 877–880 (2010). Article CAS Google Scholar * Feng, X. et al. Effects of nanotwins on

the mechanical properties of AlxCoCrFeNi high entropy alloy thin films. _Scr. Mater._ 139, 71–76 (2017). Article CAS Google Scholar * Liontas, R. & Greer, J. R. 3D nano-architected

metallic glass: size effect suppresses catastrophic failure. _Acta Mater._ 133, 393–407 (2017). Article CAS Google Scholar * Montemayor, L. & Greer, J. Mechanical response of hollow

metallic nanolattices: combining structural and material size effects. _J. Appl. Mech._ 82, 071012 (2015). Article Google Scholar * Meza, L. R. et al. Resilient 3D hierarchical architected

metamaterials. _Proc. Natl Acad. Sci. USA_ 112, 11502–11507 (2015). Article CAS Google Scholar * Peng, S. et al. Additive manufacturing of three-dimensional (3D)-architected CoCrFeNiMn

high-entropy alloy with great energy absorption. _Scr. Mater._ 190, 46–51 (2021). Article CAS Google Scholar * Tancogne-Dejean, T., Spierings, A. B. & Mohr, D. Additively-manufactured

metallic micro-lattice materials for high specific energy absorption under static and dynamic loading. _Acta Mater._ 116, 14–28 (2016). Article CAS Google Scholar Download references

ACKNOWLEDGEMENTS The authors gratefully thank the Shenzhen Science and Technology Innovation Committee for the funding support under grant JCYJ20170413141157573. Part of this project was

supported by City University of Hong Kong (Project Nos. 9610461 and 9680108), the Key Research and Development Program of Shaanxi (Program No. 2020GY-252), and the National Natural Science

Foundation of China (NSFC) Project 11922215. AUTHOR INFORMATION Author notes * These authors contributed equally: James Utama Surjadi, Xiaobin Feng AUTHORS AND AFFILIATIONS * Department of

Mechanical Engineering, City University of Hong Kong, Kowloon, Hong Kong SAR, China James Utama Surjadi, Xiaobin Feng, Rong Fan, Weitong Lin, Xiaocui Li & Yang Lu * CityU-Xidian Joint

Laboratory of Micro/Nano-Manufacturing & Nano-Manufacturing Laboratory (NML), Shenzhen Research Institute of City University of Hong Kong, 518057, Shenzhen, China Xiaobin Feng & Yang

Lu * School of Automotive Engineering, Dalian University of Technology, Dalian, Liaoning, China Rong Fan Authors * James Utama Surjadi View author publications You can also search for this

author inPubMed Google Scholar * Xiaobin Feng View author publications You can also search for this author inPubMed Google Scholar * Rong Fan View author publications You can also search for

this author inPubMed Google Scholar * Weitong Lin View author publications You can also search for this author inPubMed Google Scholar * Xiaocui Li View author publications You can also

search for this author inPubMed Google Scholar * Yang Lu View author publications You can also search for this author inPubMed Google Scholar CORRESPONDING AUTHOR Correspondence to Yang Lu.

ETHICS DECLARATIONS CONFLICT OF INTEREST The authors declare no competing interests. ADDITIONAL INFORMATION PUBLISHER’S NOTE Springer Nature remains neutral with regard to jurisdictional

claims in published maps and institutional affiliations. SUPPLEMENTARY INFORMATION SUPPLEMENTARY INFORMATION MOVIE S1 RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a

Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit

to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are

included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and

your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this

license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Surjadi, J.U., Feng, X., Fan, R. _et al._ Hollow medium-entropy

alloy nanolattices with ultrahigh energy absorption and resilience. _NPG Asia Mater_ 13, 36 (2021). https://doi.org/10.1038/s41427-021-00306-y Download citation * Received: 18 December 2020

* Revised: 24 February 2021 * Accepted: 11 March 2021 * Published: 16 April 2021 * DOI: https://doi.org/10.1038/s41427-021-00306-y SHARE THIS ARTICLE Anyone you share the following link with

will be able to read this content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt

content-sharing initiative