Play all audios:

ABSTRACT Silicon photonics has developed into a mainstream technology driven by advances in optical communications. The current generation has led to a proliferation of integrated photonic

devices from thousands to millions-mainly in the form of communication transceivers for data centers. Products in many exciting applications, such as sensing and computing, are around the

corner. What will it take to increase the proliferation of silicon photonics from millions to billions of units shipped? What will the next generation of silicon photonics look like? What

are the common threads in the integration and fabrication bottlenecks that silicon photonic applications face, and which emerging technologies can solve them? This perspective article is an

attempt to answer such questions. We chart the generational trends in silicon photonics technology, drawing parallels from the generational definitions of CMOS technology. We identify the

crucial challenges that must be solved to make giant strides in CMOS-foundry-compatible devices, circuits, integration, and packaging. We identify challenges critical to the next generation

of systems and applications—in communication, signal processing, and sensing. By identifying and summarizing such challenges and opportunities, we aim to stimulate further research on

devices, circuits, and systems for the silicon photonics ecosystem. SIMILAR CONTENT BEING VIEWED BY OTHERS INTEGRATED SILICON PHOTONIC MEMS Article Open access 20 March 2023 SINGLE-CHIP

SILICON PHOTONIC ENGINE FOR ANALOG OPTICAL AND MICROWAVE SIGNALS PROCESSING Article Open access 01 June 2025 THE POTENTIAL AND GLOBAL OUTLOOK OF INTEGRATED PHOTONICS FOR QUANTUM TECHNOLOGIES

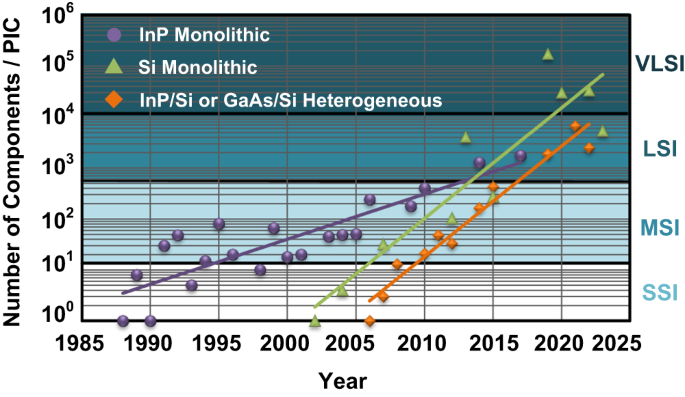

Article 23 December 2021 THE GENERATIONAL ROADMAP Figure 1 maps the evolution of silicon photonics1,2. Silicon-based photonic integrated circuits (PICs) were introduced in 19853 and

low-loss waveguides in a thick silicon on insulator (SOI) process demonstrated in 1991–924,5. Various optical devices were next demonstrated6, and soon, silicon photonics was in the

small-scale integration (SSI) era—with 1-to-10 components on a PIC. They included demonstrations of high-speed pn junction modulators7,8,9 and photodetectors (PDs)10,11,12,13, as well as

heterogeneous integration of a III-V laser to a silicon PIC14. The next era ushered in the commercial success of silicon photonics. With 10-to-500 components on a PIC, this medium-scale

integration (MSI) era saw successful demonstration and adoption of Mach-Zehnder modulator (MZM) in intensity-modulated direct-detect (IMDD) transceivers within data centers—both

single-wavelength15 and multi-wavelength16,17,18,19. Microring-modulator (MRM)-based IMDD transceivers (see Fig. 2a) demonstrated the multiplexing and energy-efficiency benefits of PIC

technology20,21,22. Coherent transceivers in silicon photonics/electronics platforms proved that the technology could compete in performance with their LiNbO3 photonic and III-V electronic

counterparts23,24,25. Besides communications, silicon photonics also found new applications such as evanescent-field biosensors26. Silicon photonics is now embarking on the next era of

large-scale integration (LSI)—towards 500-to-10,000 components on the same chip. Applications for LSI include LIDAR (see Fig. 2b)27,28,29,30,31,32, image projection33, photonic switching34,

photonic computing35,36,37,38,39, programmable circuits40, and multiplexed biosensors41. Even VLSI (>10,000 components) prototypes have now been demonstrated30,32,34. In the field of

communication, which has been the essential market driver for silicon photonics, silicon photonics has transformed from a challenger technology in the SSI era to arguably a dominant

technology in the MSI era for intra-, and inter-datacenter interconnects, and it is poised to become the incumbent technology in the LSI era. For co-packaged optics (CPO) to succeed,

high-performance computing to scale22, and disaggregated computing to become a reality42, silicon photonics will be pivotal. SILICON PHOTONICS: TECHNOLOGY PERSPECTIVE Through the generations

of CMOS process development, many materials were added to silicon to reduce the Power, improve the Performance, and shrink the Area—often called the PPA metrics. The additions include Al

and Cu for metal traces, Ge for inducing strain and enabling heterojunction BJTs, and silicon nitride (SiN) for passivation and diffusion barriers. The CMOS R&D budgets and commercial

markets are orders of magnitude larger than for silicon photonics, so it is natural for silicon photonics foundries to learn from and adopt the innovations from CMOS processes. Hence, we

have seen a similar trend in silicon photonics process development. Besides p/n dopants for high-speed modulation, two materials that are now natively supported by several foundries are (1)

Ge high-speed photodetectors43, and (2) SiN to expand the wavelength range, enable higher optical power, and support waveguides with lower loss and better phase control in interferometric

devices44. Shrinking the area will be a key focus for the next decade of silicon photonics process development for the LSI and VLSI era. In reality, the biggest density limitations rarely

come from device size; the spacing between waveguides to eliminate crosstalk is much larger than the size of the actual waveguides. For radio-frequency (RF) devices, spacings between active

elements—which are microns in critical dimension—are often in the hundreds of microns, to eliminate RF crosstalk. Shrinking these ‘blank spaces’ requires very detailed systems-level

simulation and aggressive multi-physics modeling, and will be at the heart of making chips smaller, cheaper, and higher density. The passives themselves are generally limited in size

reduction by the index contrast and the operating wavelength of 1–2 μm. There is still some headroom with the use of inverse design techniques to shrink passive building blocks, but the

waveguide itself cannot really shrink much below today’s 400–500 nm width for silicon platforms. However, significant scaling is still possible in the optical I/O couplers and high-speed

modulators. For coupling to optical fibers, V-grooves with edge couplers provide low-loss, easy-to-package connectivity at the cost of a considerable chip area. Edge couplers without

V-grooves are smaller but require more precise active alignment and surface treatment (polishing, dicing), thereby increasing cost. Multicore fibers are an attractive solution for

efficiently using limited photonic beachfront around the edges of a chip45. The main alternative coupling approach is through grating couplers, which are compact, provide the flexibility of

positioning on the chip surface, enable wafer level testing, and can also be realized with low insertion loss (IL), but suffer from polarization and temperature sensitivity and lower optical

bandwidth46. Passive alignment packaging techniques, such as photonic wire bonding (PWB)47, offer an attractive potential alternative. Using computer vision and automation, PWBs can be

fabricated in polymer photoresist through two-photon absorption between two coupling sites allowing up to 30 μm of offset. Simple alignment markers are used to locate the coupling sites, and

the sites do not require strict pitch or large footprints, thereby providing a passive-aligned, low-loss, scalable port count. In another passive alignment technique for pluggable

connection, the complexity and accuracy requirement can be moved from fiber assembly to wafer-level manufacturing, where a fiber-receptor die can be flip-chip integrated to the silicon

photonic die with a glass spacer48. Using a combination of V-grooves and mirrors in the fiber-receptor die, and mirrors and surface couplers on the silicon photonic die, a confocal imaging

assembly tolerant to >10 μm relative displacements of the two dies can be realized, providing a passive-aligned, low-loss, scalable port-count and pluggable connector48. More reliability

studies for these passive alignment-based assemblies will be helpful for broad adoption. E/O MODULATION The central quest for the next decade in shrinking photonic chips and thus increasing

density is to find the elusive ‘ideal’ modulator in silicon photonics—small in length (L), requiring a small drive voltage to incur a _π_ phase shift (_V__π_), offering low propagation loss

(_α_) and IL, and for several applications, highly linear and with large −3 dB E/O bandwidth (BW)49. Also, this modulator is preferably a phase shifter, as this enables higher-order coherent

modulation formats. HIGH-SPEED MODULATORS The often-used efficiency figure-of-merit (FoMefficiency) of waveguide-based modulators (Table 1) is _α__V__π__L_. For MRMs, which are very

compact, the loss due to _α_ becomes less critical50, and a better FoMefficiency inculcates the IL and _V_pp (the peak-to-peak voltage swing for a specific optical modulation amplitude or

OMA). All modulators suffer from a tradeoff between FoMefficiency and E/O BW49,50,51. Finally, the power consumed in the driver depends on the modulator impedance as seen by the driver. A

resistive impedance (a terminated traveling-wave modulator) consumes static (DC) and dynamic (AC) power, whereas a high impedance (capacitive) consumes primarily dynamic power. A high IL

also is a proxy for higher power consumption since the laser power needs to be increased to compensate for the losses. Besides the topology, the PPA metrics for a modulator depend on the

material and mechanism used for modulation. Table 2 shows the different materials used for modulators in various silicon photonic processes. p-n dopants utilizing the free-carrier plasma

dispersion are natively available in all commercial silicon photonic foundries today, supporting 60 GHz or even higher E/O BW. Currently, the commercial market is dominated by such devices,

in the form of traveling-wave MZM modulators52. Plasma dispersion in Si leads to mediocre FoMefficiency, with high IL for average OMA. Carrier accumulation allows for shorter MZMs, but with

BW limitations53,54. When implemented as MRMs, the devices are much smaller, but IL and OMA remain suboptimal to support LSI/VLSI ICs. With Ge PDs already supported by most commercial

silicon photonics foundries, various teams have attempted to use GeSi, a related but not identical technology, to implement a better modulator. GeSi electro-absorption modulators (EAM) based

on the Franz-Kelydysh effect can operate in the C/L band at high E/O BW. However, they are generally not optically broadband since they use band-edge modulation for absorption. For O-band

operations, modulators utilizing the quantum-confined Stark effect (QCSE) still suffer from a large IL55. While there have been multiple academic and commercial efforts in this space, it is

unclear whether these modulators will find their way into future generations of commercial devices. Heterogeneous integration of modulator technologies—InP, thin-film LiNbO3 on insulator

(LNOI), or thin-film BaTiO3 (BTO)—with Si can be done using die-to-die, die-to-wafer, or wafer-to-wafer direct (molecular) bonding or adhesive-assisted bonding. Die-to-wafer bonding provides

the flexibility of using known-good dies, increasing yield. Wafer-to-wafer bonding remains expensive because the size mismatches between the SOI acceptor wafers (200 mm or 300 mm) and the

modulator donor wafers (150 mm or smaller) lead to wastage. Integration proximity of the (dissimilar) materials in direct bonding facilitates superior optical coupling and heat

transportation between them56. However, very smooth and clean surfaces are required. Chemical mechanical polishing (CMP) procedures, already used in high-volume manufacturing (HVM) for

heterogeneous direct bonding of InP to Si for lasers, must be optimized for a scalable modulator integration pathway. Annealing is needed for strong molecular bonding and outgassing, but the

pre-processed SOI wafer significantly restricts the annealing temperature. Therefore, “low-temperature” annealing at <350 ∘C is usually used, but this necessitates developing custom

outgassing techniques and direct bonding recipes that require extensive resources to improve yield. Mismatches in the coefficient of thermal expansion (CTE) must also be minimized. Surface

topography requirements can be relaxed, and bonding strengthened using an intermediate adhesive57,58,59 but thermal dissipation, long-term stability, optical power handling, and drift

properties need to be studied further60. Heterogeneous integration of InP to CMOS has already been of interest for electronics61 and photonics. For photonics, it has paved the path for laser

integration in HVM of IMDD transceivers19 and is being used for SOA integration22. In light of these integration efforts, InP/Si modulators remain promising62,63,64. InP/Si EAMs for C/L/O

bands have been demonstrated and are available in at least one silicon photonics foundry. Both O2 plasma-assisted62 or SiO2 covalent direct wafer bonding techniques56 have been adopted.

However, the bandgaps required for optimal laser and modulator operation differ, significantly complicating the heterogeneous integration. The state-of-the-art in both FoMefficiency and E/O

BW needs to be remarkably improved for InP modulators to be popularly adopted as the integration of choice for the next generation of silicon photonics. In general, compatibility to Ge PD

processing65 and reflow66 would be a requirement for a new modulator technology to be adopted by the commercial foundries. The most ‘pure’ electro-optic modulation relies on the Pockels

effect, which provides an intrinsically very high E/O BW, even exceeding 100 GHz57,67,68,69,70, but these materials face challenges with CMOS integration, and have little or no prior history

of integration with CMOS for electronics (compared to Ge and SiN which were already introduced in CMOS electronics). LNOI modulators57,68 provide low IL and have been integrated with

sources and PD70. However, their _α__V__π__L_ product needs to be improved further. Lithium, a contaminant in CMOS foundries, restricts FEOL integration. Hybrid integration of etched LNOI

modulators71 (both MZMs and MRMs) to silicon PICs remains a pragmatic solution. Heterogeneous integration of unetched LN to silicon is achieved with BEOL integration or encapsulation

technologies. Avoiding etching also avoids structural defect formation, Nb depletion, and heat and pyroelectric charge build-up issues associated with etched LNOI processes57. Conversely,

improving modal confinement becomes difficult. Since the optical mode is controllably distributed in the unetched LN slab and edge Si rib waveguides, achieving a sharp bending radius for

MRMs remains challenging60. The large size of LNOI/Si modulators also prevents adoption in applications requiring many modulators. Polymer silicon-organic-hybrid (SOH)67,72 and

plasmonic-organic-hybrid (POH)69 require poling and hermetic sealing, creating significant challenges to making stable devices. Their high-temperature reliability and reflow compatibility

need to be further demonstrated, although recent results are promising72. POH modulators, even though they look attractive in the PPA metrics, further suffer from compatibility with CMOS SOI

foundries. Good plasmonic metals (Cu, Ag, Au) are also serious contaminants, and need diffusion barrier layers (e.g., TaN) which are optically very lossy. Polycrystalline layers of other

ferroelectric thin-film materials such as BTO show much larger Pockels coefficient (expressed in pm/V) than LNOI73 and comparable to polymers74, and recent demonstrations of large E/O

BW65,75 make them promising. Note that a large Pockels coefficient in the device is important, which requires a good overlap of the electric modulation field and the propagating optical

mode49,72. As part of the direct wafer bonding process, BTO thin films are fabricated first using molecular beam epitaxy deposition on donor wafers, and then directly wafer bonded to

interlayer dielectric/SiO2 of the planarized acceptor SOI wafer using intermediate alumina layers as an adhesive. BTO also requires poling to compensate for hysteresis from ferroelectric

domain switching (albeit only ~ 1V DC compared to much larger voltages needed for polymer modulators)65. Sources of propagation loss include scattering from waveguide sidewall roughness and

residual oxygen vacancies in the BTO thin film—areas for further improvement. BTO also has a lower refractive index compared to Si (nBTO = 2.38, nSi = 3.47 @ 1550 nm) and a significantly

large RF relative permittivity that can increase capacitances and velocity mismatch between the optical and electrical fields. Improving all PPA metrics and HVM suitability is crucial for

commercial foundries and LSI applications. However, thanks to the numerous photonic applications, there will always be a need for exceedingly high E/O BW modulators, and several prototyping

and R&D foundries will continue to address the related fabrication challenges. Finally, although > 100 GHz E/O BW modulators are attractive for both telecom and data center

applications, they require electronics capable of driving them at such speeds. Unless _V__π_ (or _V_pp) is reduced significantly, such electronics will consume a lot of power, regardless of

CMOS/BiCMOS/III-V implementation. PHASE-SHIFTERS FOR TUNING AND SWITCHING Many photonic applications require phase shifters that consume little or no power and have a low _α__V__π__L_ for

configuration, tuning and switching. For certain applications, these phase shifters should be fast as well, but 10s of GHz E/O BW is not needed. While in many circuits light only passes

through one high-speed modulator, it will have to traverse many low-speed phase shifters for tuning and switching, thereby compounding the penalty of power consumption and _α__V__π__L_.

Metal heaters (or doped waveguides) utilizing the thermo-optic effect are available in all foundry platforms today. They have 1–10 μs response time, and consume considerable power,

generating thermal crosstalk, and thus limiting LSI/VLSI scaling. But they do not introduce optical loss, a significant advantage over other alternatives. Improving thermal insulation

reduces their power consumption by > 10 × at the expense of an even higher response time76. Even > 100 × improvement is possible by folding the waveguides to increase interaction with

the metal heaters, but that results in an IL77. The final set of materials and techniques listed in Table 2 are attractive alternatives to heaters. They include liquid crystals (LC),

MEMS/NOEMS, and phase change materials (PCMs). LC on silicon (LCOS) tuning for display applications has been demonstrated at a large scale, and LC has also been the technology of choice for

free-space wavelength-selective switches. As phase shifters, they leverage birefringence to demonstrate a strong electro-optic effect. The alignment of the LC molecules can be controlled by

applying electrical voltage (<1 V) without drawing any significant static or dynamic current (nA). Hence, they consume extremely low power but currently suffer from IL78, although very

low IL has been demonstrated in visible band recently79. The liquid integration on chip brings its own set of temperature and packaging challenges, both at the BEOL manufacturing and

packaging stages, and requires steps such as etching, inkjet spotting or injection without affecting other devices such as grating couplers, initial LC alignment, and sealing. However, the

challenges are surmountable. PCM-based non-volatile memory has achieved HVM in the electronics industry80 and is being explored for neural network applications81. The use of PCM in silicon

photonics promises compact tuning capabilities, where the optical phase shift is obtained by tuning the state of the material from amorphous and crystalline. As non-volatile phase shifters,

they can sustain their state without any static power consumption. But they suffer from IL and significant dynamic power consumption82,83, rendering them suited to only selected applications

where sporadic phase shift is needed. MEMS/NOEMS-based phase shifters are inherently low power84, and have been demonstrated with multiple foundries35,85,86. A promising phase shifting

mechanism in NOEMS uses the applied voltage to mechanically move the waveguide structure, changing the optical mode field distribution and hence the effective refractive index87. A dual slot

structure can be used87, where the dual slots (actuation regions) within a p-i-n junction act as capacitors that get charged or discharged with the applied voltage without drawing

significant current, at speeds comparable to metal heaters but without the thermal crosstalk. Compact length, <1 V drive voltage, low power, and negligible IL87 make NOEMS phase shifters

an appealing choice for the next-generation phase shifter technology in silicon photonics. Challenges such as hermetic sealing with optical and electrical feedthroughs are solvable88,89.

Finally, materials such as BTO promise high-speed modulation and compact, low-power phase shifting90, at the cost of very steep technical and economic integration challenges. As phase

shifters, their IL must be considerably reduced to compete with other technologies. Integration of emerging materials such as graphene91 and Indium Tin Oxide (ITO)92 into silicon photonics

has been demonstrated. Being relatively newer technologies and friendly to CMOS SOI integration, more progress is expected to improve their performance. LASER INTEGRATION Silicon’s indirect

bandgap prohibits efficient optical gain that is necessary for a laser (CW carrier) on the PIC. This deficiency requires alternative materials or methods to introduce light sources on a

silicon chip, and the developments over the past decades have led to different solutions (Fig. 3)93. The conventional technique is to fiber-attach the PIC with a laser and an isolator (Fig.

3a). More scalable approaches integrate III-V gain materials with the PIC without fiber. But an isolator is still needed if the laser cannot tolerate reflections. Off-chip isolators perform

well but are bulky and increase packaging complexity and cost. Pragmatically, it is often possible to design chips and packages in such a way that back-reflections are not a limiting factor;

the high losses in the transmit path provide a barrier between the outside world and any light source. And the cost of compact isolators can be managed when designed into the package.

On-chip reflection-control approaches (Fig. 2) that can eliminate the need for bulky isolators include carefully designing the photonic components to reduce reflections below the tolerance

threshold of the laser, reducing the reflection sensitivity of the laser by using quantum dot gain regions with low linewidth enhancement factor94, monolithic integration of magneto-optical

materials (e.g., Ce:YIG)95, spatiotemporal modulators96, or active reflection cancellation circuits97. A generalized, low-cost, scalable, on-chip, low-loss, low-power, and compact solution

robust to near- (coherent) and far-end (incoherent) modulated multi-wavelength reflections remains a research problem. A pragmatic solution for laser integration is hybrid integration, where

multiple chips from different material technologies are co-packaged together. For example, (sub)-mm DFB lasers, manufactured by the millions for datacom applications at low cost and high

yield and pre-tested, can be co-packaged with a silicon photonic chip or even with a wafer. A 2.5D integration technology that has been commercially successful involves packaging known-good

lasers with the silicon photonic die using epoxy, ball-lens, and isolator (Fig. 3b)43. Other 2.5D techniques include using butt coupling98 or photonic wire bonding99 to enable relaxed

alignment tolerances (Fig. 3c). These 2.5D techniques are adequate for several bespoke silicon photonic applications today. Hybrid 3D integration technologies (flip-chip or micro

transfer-printing) promise to further shrink the assembly size at the cost of using the PIC area (Fig. 3d)71,100,101,102, but require high-accuracy placement and bonding. Table 3 summarizes

the PPA and other metrics for various integration schemes. The wall-plug efficiency (WPE) of most of the C/L/O band lasers is only about 10%, a metric that needs more focussed research for

improvement. With similar WPE, the coupling loss between the laser into the PIC can be instead taken as a proxy for power consumption. In the 2.5D hybrid integration, a separate laser

provides the flexibility of choosing the one with the needed optical power, and thermal management is easy. For higher power handling, SiN can be used on the PIC. There are means to improve

the linewidth of the laser from the typical linewidth of a DFB and also cancel the reflections to improve isolation97. 3D techniques with high-Q Si or SiN external cavity support linewidth

reduction down to 1 Hz and lower98,103,104, more than sufficient for applications such as coherent communication101 and automotive LIDAR. Hybrid integration also allows multiple

wavelengths71. Still, the benefits of hybrid integration vis-a-vis scaling towards > 8_λ_ WDM LSI PICs needing multiple lasers, gain elements, etc., remain to be thoroughly demonstrated.

Another commercially successful technique in HVM (>million/year)14 has been heterogeneous integration, where multiple materials or epitaxial stacks are processed together into one silicon

chip at wafer scale. Again, various strategies have been adopted105,106. They include bonding III-V chips to Si with coarse alignment followed by post-processing the Si wafer to make

quantum-well (QW) lasers (Fig. 3e)14,18,19,22. Thermal isolation of the gain medium by the buried oxide (BOX) and the mismatched CTE must be carefully addressed for high-temperature

operation, efficiency, and reliability. Placing redundant lasers helps improve the failure-in-time (FIT) rates22. Benefits of the heterogeneous approach include sub-dB coupling loss and a

mechanism to leverage the low-loss external cavity in silicon to significantly reduce the laser linewidth using self-injection locking107. Another longer term approach, desirable for

quantum-dot (QD) lasers, is to directly grow epitaxial gain material on the Si wafer108. Due to its lower linewidth enhancement factor, _α_H, QD lasers enable lower linewidth and reduced

sensitivity to reflections94,109. They also have lower threshold current density. Monolithic integration using hetero-epitaxial growth (Fig. 3f), where the III-V substrate is not even

needed, remains the end goal, with several recent progress and more to come1. Multiple silicon photonic foundries are developing hybrid or heterogeneous laser solutions. For scalability

purposes, the foundries will likely favor a technology that lends itself to multi-wavelength support, which is crucial for several LSI applications. It is likely that scale-out will be

supported first by bonding multiple single-wavelength lasers22. Comb lasers110 such as passive semiconductor mode-locked lasers (SMLLs)111 are being actively pursued by various research

groups. DFB arrays ensure large output optical power in each wavelength, whereas, in the SMLLs, the power is split between the wavelengths. The presence of the saturable absorber further

lowers the total (and hence per wavelength) output power of SMLLs. However, an SMLL is significantly smaller than a DFB array. The linewidth of passive SMLLs111 is usually lower than DFB

arrays22. More R&D is expected for SMLLs to demonstrate higher power, reliability, and lifetime in the next decade. Such requirements for DWDM applications are even more stringent, and

any temperature drift creates inter-channel crosstalk112,113. AVALANCHE PHOTODETECTORS Most of the silicon photonic applications are constrained by limited output power and WPE of the laser,

and the high IL in the circuits. An alternative is to improve the SNR at the detection stage (Fig. 2). Low-voltage APDs which have large −3 dB O/E BW, high overall responsivity114, and

simultaneously low noise will be beneficial for receiver signal-to-noise ratio (SNR) improvement115,116. It is important to note that the overall responsivity (in A/W) and low noise is

crucial. A large multiplication gain for an APD which has a poor intrinsic responsivity does not lead to a superior performance. Although relatively easier to achieve in Si APDs at 850

nm117, simultaneous (at the same bias voltage) optimization of gain-BW-noise has remained challenging for low-voltage Si/Ge APDs118 or Si resonant APDs119,120 in C/L/O bands. In comparison

to Ge PDs, APDs generally have inferior BW, linearity and power handling, which limits their use in various applications. APDs also need to be biased optimally and stabilized for temperature

and voltage drift, but that is less challenging117 than what has already been demonstrated for microring circuits50. DELAY Several silicon photonic applications require hundreds of

picoseconds to nanoseconds of delay. Examples include microwave photonics, optical phase-locked loops (OPLLs), frequency discriminators (Fig. 2), laser linewidth reduction circuits, OPAs,

optical coherence tomography (OCT), and gyroscopes. Many of these applications also require tunability in 10 s of picoseconds and broadband operation121. Realizing such a delay in silicon

photonics with low-loss and low-area has been very challenging122. Resonant devices provide a narrowband delay. Si or SiN delay lines are difficult to tune and require narrow bends leading

to significant scattering and radiation losses. Shallow etched ridge waveguides or ultrathin waveguides break compatibility with the 220-nm processes. Modifying the fabrication process

without sacrificing the performance of other photonic components remains challenging123. SILICON PHOTONICS: SYSTEMS PERSPECTIVE PHOTONICS & ELECTRONICS INTERPLAY Silicon PICs almost

always exist in conjunction with electronic ICs (EICs). When we look at systems based on photonic chips, the landscape today is almost 100% dominated by data communication, and we expect

this to continue for the near future. In this context, EICs serve two purposes (Fig. 2): (1) Enable E/O and O/E conversions of the end-to-end data. (2) Bias, control and compensate for

temperature and fabrication variations. Thus, photonics serve electronics by providing the data links, and electronics serve photonics by providing control and readout and digital signal

processing (DSP). A major difference between photonics and electronics is that photons don’t interact and thus are excellent for transmission of information, whereas electrons interact and

repel each other and thus make good switches and computing elements. Each silicon photonic switch therefore requires a corresponding electronic switch. On the whole, the number of

transistors in the EIC that must accompany an LSI PIC are orders of magnitude larger than the number of components in the PIC. Here lies a natural interplay, since transistors consume much

lower power in (1) switching, (2) providing gain (both linear and limiting), and (3) offering high precision, while being orders of magnitude smaller than the photonic components124. On the

other hand, the photonic components (1) enable lower frequency-dependent loss when moving data over a longer distance compared to copper, (2) may provide lower latency through asynchronous

and repeaterless data movement, and (3) ease parallelism of very high-speed data on an optical waveguide (through WDM). When the data is already in the optical domain, photonic signal

switching or processing can become attractive. The former is a widely deployed technology, while the latter has yet to make the leap from research to product to replace DSP functionality.

Thus, it is good to be cognizant of the respective virtues of the PIC and EIC technologies. For example, the E/O and O/E overhead of processing electronic data in the photonic domain must be

carefully analyzed. Conversely, silicon photonics provides opportunities to shrink large optical systems, and bring new applications (such as in sensing and imaging) to reality, which

electronics cannot enable by itself. Finally, silicon photonics operates on a carrier wave of hundreds of THz, while silicon electronics is limited to sub-THz. Such differing attributes open

attractive co-design opportunities, such as designing electronic clocks with ultra-low phase noise125. PHOTONICS & ELECTRONICS ECOSYSTEM It is insightful to look at the electronics

industry ecosystem briefly. Moore’s law demonstrates that the cost per component goes down with every generation of CMOS technology reducing the critical dimensions of the transistors. This

scaling is enabled by an exponential increase over time in the economic scale of the semiconductor industry, which allows the industry to pay for ever more expensive foundries and process

development. Foundries enable many users to access these advanced processes, without each needing to pay to develop the process on their own. At the most extreme, the MPW (multi-project

wafer) runs that the foundries host allow multiple users to share the costs of a single wafer run to develop products cost-efficiently. As processes mature, yields go up, and costs come

down. The foundries and third-party intellectual property (IP) providers enable a process design kit (PDK) and design IP libraries, allowing the customers to build incredibly complex

electronic circuits and get them right the first time. By relying on both proven devices and proven circuit-level IP, the designers can focus on system-on-chip (SoC) integration without ever

touching the transistor level in several cases. Once the chips are fabricated, there is a rich ecosystem of test houses, packaging service providers, and so forth. Electrical wire-bonding

(Fig. 4a) and flip-chip bonding (with C4 bumps and microbumps, Fig. 4b) are reliable and popular means of packaging, with the latter providing more bumps instead of just peripheral

connections. More advanced packaging techniques (see Fig. 4) such as through-silicon via (TSV), TSV-less interposers, and heterogeneous integration are used to improve signal integrity,

power and thermal distribution, and die yield by breaking complex and large SoCs into smaller chiplets126. Because the FPGAs, GPUs, and CPUs are produced in HVM, the overall cost still goes

down despite the complex packaging techniques. Nevertheless, judicious packaging decisions are made to avoid unnecessary complexity; generally, the simplest package is best, and advanced

packaging techniques (chip on wafer, chip stacking, etc.) tend to be introduced only when no other alternative is feasible. The photonics industry has several similarities but also many

stark differences. Just like in the electronics industry, increasing the number of photonic components is not always about reducing cost, but is often about providing new functionality,

improved performance, or reduced area per component. MPW runs are now available at many foundries, although mature PDKs, and abstraction languages are still in very early stages. Third-party

IP support is mostly non-existent thus far. Companies wall off the most advanced PIC processes to protect their investment and IP (reminiscent of the early decades of the CMOS industry,

acting as virtual integrated device manufacturers (IDMs), maintaining differentiation at the process and PDK level. Meanwhile, academic research mainly focuses on improving the devices.

Photonic foundries face a significant dilemma: Their customers often demand that they customize their processes, which involves a great deal of R&D expense, and endangers the reliability

and yield of the final wafers. Driving customers into a standard process is the solution for this, but in order to do that, the customers need to see significant value in stability and in a

settled PDK and IP ecosystem; only a few designers see the world this way, because so many of the members of the design community today were trained as device people, rather than SoC

designers. Changing process parameters often seems to such designers to be the easiest way to generate performance differentiation, but the downstream costs for such changes can be very high

from a reliability and process maintenance perspective. As more designers who are used to the idea of settled PDKs graduate and come into the field, disruptive process changes will slowly

become less and less common; the foundries will also likely grow ever more resistant to process changes from customers that are not justified by substantial purchase commitments. The overall

yield for silicon photonics products is still lower than their CMOS electronic counterparts. Additional factors at the process, design, and packaging level account for the difference:

fabrication127,128 and thermal sensitivity, lack of robust PDK components and variation-and-mismatch aware models127,128, design flow methodologies still missing hierarchical simulations,

schematic driven layout and layout-versus-schematic verification127, custom process modifications for specific components, challenges with epitaxial growth, Ge integration for

photodetection, integration of laser (whether at the die or package level), laser FIT, and fiber connectivity. Only a handful of HVM silicon photonics products are shipping today, requiring

the fab to timeshare the production with other processes, and adding another source of yield impact. PHOTONICS & ELECTRONICS CO-INTEGRATION The option to integrate the PIC with the EIC

has been around since the first commercially successful silicon photonic product1,127,129. Developing a monolithic EPIC process (Fig. 4e), starting with a CMOS (or BiCMOS) SOI process and

optimizing it for photonic applications, has been demonstrated several times130,131,132 successfully. From the perspective of commercialization and time-to-market, a monolithic EPIC often

‘seems to’ be the superior technology of choice (Table 4). High-speed circuits such as drivers and TIAs can be colocated next to modulators and PDs, reducing parasitics and power

consumption133. Controllers (thermal, wavelength) can be designed and placed next to the photonic components without needing dedicated pads. For LSI applications, a monolithic EPIC can

simplify packaging complexity significantly. However, when the die area is dominated by photonics, photonic components being orders of magnitude larger than their electronic counterparts124,

the overall die cost can increase significantly without arguably making full use of CMOS devices. This analysis has to be done case-by-case for individual products. In principle,

microring-based circuits appear to be very appealing for monolithic EPIC processes until the next-generation modulator with a superior FoMefficiency is developed (see the “High-speed

modulators” section). But to conclude whether they make sense in a given, specific application, a complete systems analysis is necessary; microrings come with considerable control overhead

and performance tradeoffs, especially at very high speeds. If the application requires high-speed ADC/DAC and especially DSP (Fig. 2), another finFET EIC must also be added to save power

consumption, as the fastest monolithic EPIC process today in 45-nm CMOS SOI is still several generations slower (in fanout delay) than finFET processes. Integrating photonics directly onto

CMOS wafers below the 45 nm node is unlikely to occur in the next few years; doing so does not make economic or technical sense in a world where chip-on-wafer bonding between PICs and scaled

microelectronics is comparatively straightforward. Other possibilities for EPICs have also been explored. Adding photonics to an older generation CMOS process leads to high-power and slower

drivers and TIAs, leading to worse transceiver designs and rendering them unattractive to the biggest customers of silicon photonics—datacom and telecom. Nevertheless, such a process is

appealing to university researchers as it opens up opportunities to co-design and innovate new EPIC circuits134,135 at low cost and packaging effort. On the other hand, multiple efforts are

underway to integrate transistors onto the same wafers as silicon photonic devices136. However, doing so has thus far involved unacceptable compromises to the performance of the bipolar

electronics. Most of the silicon photonic transceivers in HVM today are based on a 2.5D integration approach, where the PIC and EIC(s) are designed, sized, optimized, tested in their best

respective processes, and then flip-chipped to an interposer substrate17,19,24,25,137 (Fig. 4b, Table 4). The EIC process can be chosen from one of the many CMOS/SiGe foundries. Multiple EIC

chips can also be flip-chipped, such as (1) a SiGe chip or scaled-CMOS chip with a reasonably large breakdown voltage to permit high-swing drivers and a reasonable switching speed to

support the RF speed requirements, and (2) an advanced FinFET chip for DSP/ADC/DAC138. An EIC process with faster transistors may even compensate for the parasitic capacitance due to

additional pad, ESD, and routing (compared to a monolithic EPIC solution). For LSI applications where most PIC components require electronics at a relatively low speed (such as LIDAR),

flip-chip solutions seem reasonable32. However, for LSI applications that need many high-speed drive/readout lines, a flip-chip solution means many RF traces on the interposer, leading to

complexity and crosstalk considerations. In either case, the size of the PIC is increased due to the necessity of many I/O bumps, though with microbumping and copper pillar technologies to

realize a stacked flip-chipped 2.5D package139,140 (Fig. 4b, bottom), these increases are often commercially negligible. The parasitics and interconnects are also reduced compared to their

side-by-side counterparts. A hybrid 3D integration can be considered in some cases, where the EIC is flip-chipped on the (larger) PIC chip and uses advanced techniques such as TSVs or

through-oxide vias (TOVs) (Fig. 4c, Table 4). The RF lines still need to be routed from the small EIC to several places on the PIC, which remains challenging. A WoW heterogeneous 3D

integration is also being researched where the photonics wafer is flipped and vertically attached with the CMOS wafer through oxide-bonding, the silicon handle on the photonics wafer is

removed, and TOVs are formed at the wafers’ interface141,142; further improvements are expected for the performance of photonic components in such an integration technology (Fig. 4d, Table

4). One possibility is to use multiple EICs 3D integrated on the PIC. Overall, the application, performance specifications and the volume of shipments (affecting the cost) will decide

whether a more expensive monolithic EPIC with simpler packaging, a multi-chip 2.5D integration with more complex packaging, or a 3D integration with more complex processing/packaging is the

right choice (Table 4). We expect that all of these scenarios will co-exist, just like in the electronics ecosystem. SILICON PHOTONICS: APPLICATIONS PERSPECTIVE In this section, we describe

the top technical impediments to the success of various silicon photonics applications (Table 5), connecting them to some of the challenges and opportunities discussed in previous sections.

We limit the impediments to PIC/EIC technology only, excluding economic, regulatory, market, and other factors such as chemistry, biomarkers, quantum advantage, etc. We also do not delve

into the benefits of silicon photonics for these applications since most of the previous works describe them in detail. For IMDD transceivers (XVRs) to further improve their energy

efficiency (pJ/b) and scale to higher data rates, the modulator FoMefficiency needs further reduction, and the −3 dB E/O BW needs to be improved towards 100 GHz. Improving the WPE of lasers

is essential for most applications but especially crucial for communication and computing applications. Efficient multi-wavelength light sources are also needed with adequately large power

in each wavelength. Low-noise, large gain-bandwidth APDs in O/L/C bands could provide an SNR improvement without significant power consumption penalty, but historically their bandwidth,

linearity, noise, and power handling characteristics have prevented their use at the highest bandwidths. Finally, amplifying PD signals using high-gain, low-noise TIAs remains a crucial

challenge. Several equalization-based techniques have been recently demonstrated to limit the noise using low-BW TIAs143, but most operate on the assumption that the receiver clock is

available. For coherent transceivers to be competitive inside data centers, additional challenges (vs. IMDD) must be solved. Linearity requirements for the TIAs and drivers are more

stringent137,144, and the reliance on power-hungry DSP needs to be reduced as much as possible. One strategy being explored by researchers is moving some signal processing tasks into the

optical domain145,146 leveraging integrated photonics and analog electronic circuits. The latter requires significant electronic-photonic co-design effort, opening up several opportunities

for CMOS designers to leverage the expertise from mixed-signal and RF ICs. High throughput network switches for short-reach to long-haul markets require the phase shifters to have excellent

FoMefficiency to enable large fabrics. The switching must incur low power consumption, low loss and demonstrate a large extinction ratio. For applications that permit slower switching

speeds, insulated metal heaters in interferometric switches are currently the popular implementation choice147, but technologies such as MEMS/NOEMS look promising34. Long-term reliability

and demonstration in large-scale fabrics co-integrated with electronics and packaged with optical I/Os are needed. Polarization diversity and wavelength considerations further complicate the

scaling and packaging considerations. Applications requiring fast switching are even more challenging since high-speed modulators with comparatively inferior FoMefficiency further

deteriorate IL and extinction ratio. Regardless of the switching speed requirements, the inherent losses in large switch fabrics require optical amplification, necessitating the integration

of SOAs, ideally uncooled, for energy efficiency considerations. Practical quantum communication and computing applications require LSI-VLSI photonic components with advanced CMOS

controllers. For chip-scale discrete-variable quantum key distribution (QKD), the foremost requirements are the cryo-compatible photonic/electronic readout and control of superconducting

nanowire single-photon detector (SPD) arrays; developing low-loss, low-power cryo-modulators and cryo-compatible WDM mux/demux; and integrating single-photon source (SPS) arrays at the

transmitter in a low-noise, low-crosstalk chip-scale photonic-electronic solution. Superconducting nanowire SPDs operate at telecom wavelengths, facilitating the use of existing optical

fibers as a quantum channel. Besides massive parallelization, reducing the loss in the receiver and improving the SPD performance will help increase the transmission rate148. For quantum

computing applications, the challenges are similar, but require much larger scalability of qubit control/readout, including the photonics and low-latency control electronics149. The quality

of qubits is, of course, paramount. Scalability of control/readout degrades with IL—every photon lost degrades the capability of the quantum system in an exponential way. Ultra-low-loss

couplers are therefore needed to connect to the PIC. Photonic computing involves analog computation and processing of information within the photonic domain37,38. This requires handling

multi-level signaling150 and increasing the precision of weight control151 to ensure a high SNR. Such improvements are crucial to achieve accuracy comparable to the incumbent CMOS EIC

compute engines76. Another challenge is access to high-speed memory to prevent a memory bottleneck, especially for activations and tasks that are not weight-stationary. Photonic computing

uses high parallelism, so it is essential to reduce the IL of passive and active devices (modulators, phase shifters) and boost the output power of multi-wavelength lasers to accommodate

larger network sizes. In addition, for neural networks, efficiently implementing programmable nonlinearities stands out as a significant hurdle37. For automobile driving, silicon photonics

LIDARs are positioning themselves as a solid-state challenger to Time-of-Flight (ToF) LIDARs utilizing mechanical or MEMS-based scanning. LIDARs consist of two subsystems—ranging and beam

steering, both of which can use silicon photonics. ToF and frequency-modulated CW (FMCW) are ranging techniques. FMCW provides the benefits of (1) coherently detecting signals down to a few

photons, (2) robustness to interference from ambient sources, and (3) simultaneous distance and velocity measurement. All of the necessary components for coherent detection can be integrated

on a single chip. For beam steering, two integrated possibilities exist: (1) Optical phase arrays (OPAs), based on continuous tunable phase shifters and gratings32. Bulk optics solutions,

such as spinning mirrors and oscillating mirrors, have the advantage of being cheap, mature, and simple; displacing such solutions with an on-chip OPA will be a significant challenge. For an

OPA to emit a single beam, the grating antennas need to be spaced less than half a wavelength (in free space)—a challenging proposition for 2D beam steering on a silicon chip. Therefore,

silicon photonic OPAs typically have gratings arranged for beam steering in 1D and the wavelength of the laser is swept to steer the beam in the other direction. (2) Focal plane arrays

(FPAs) based on on-chip switch networks and grating couplers31. These include 2D FPAs, utilizing MEMS switches29,30, or 1D FPA with wavelength steering. Regardless of the solution, low-power

(10 s of nW) and improved FoMefficiency phase shifters are important, and necessary for beam steering. Improved lasers are the next challenge. For 1D OPAs or FPAs, multi-wavelength lasers

can relax wavelength tuning28. For FMCW demodulation, narrow linewidth (< 100 kHz) continuously tunable lasers (preferably without mode hopping) are crucial. Scaling and packaging

comprise the third challenge. Scaling the photonics and electronics for many emitters and phase shifters, and integrating a considerable delay121,122,123 (Fig. 2) for the laser and a complex

DSP, are both necessary. Applications in microwave photonics, such as filters and low-phase noise oscillators, have different challenges than most other applications discussed so far. The

spurious-free dynamic range (SFDR) specification for microwave filtering is quite challenging to realize in the current generation of silicon photonics. Strict linearity of the modulator and

PD is needed, and at the same time, several sources of noise (laser, PD, TIA) have to be minimized152. The goal to get an RF net gain further complicates the design. Implementing

laser-assisted microwave oscillators through silicon photonics with phase noise superior to CMOS-only counterparts also requires minimizing the laser noise, PD, and TIA noise123. Excellent

short-term and long-term stability is also needed. Silicon photonics promises low-cost and compact gyroscopes153. But to compete with their fiber-optic-based counterparts in performance,

gyroscopes in silicon photonics leveraging the Sagnac effect must demonstrate ultra-low loss in waveguides (mimicking an optical fiber), reduction in bias drift due to reflections under

extreme conditions of vibration and changing temperature (to not mask the Sagnac phase shift), and low noise for high sensitivity. Engineering of SiN waveguides has reduced the loss to 0.5

dB/m123, and further improvements are needed. Back reflections must be eliminated both on-chip and off-chip, for which on-chip isolators, reflection cancellation circuits, or self-injection

locking107 must be reliably implemented. Since a gyroscope neither requires an LSI implementation nor high-speed modulators, it is a promising bespoke application that can be successfully

realized if the challenges mentioned above are solved. Robustness to vibration also mandates a heterogenous implementation whose challenges must be solved for HVM. Silicon photonic

spectrometers for biosensing applications often require an operational wavelength incompatible with the C/L/O bands154. This becomes the most significant bottleneck, since new waveguides

(vs. the standard 220 nm) and other photonic components have to be designed, tested, and characterized155. The lasers are also challenging, and the need for broad wavelength tuning or

multi-wavelength lasers at these non-standard wavelengths poses severe difficulty. Finally, the stability and replicability of the measurements are crucial for biosensing applications, and

the performance of the PIC and laser has to be maintained despite the environmental drift. The stability and replicability requirements for evanescent-field biosensors are even more

stringent, since an invasive measurement of blood or other bodily fluid increases the user’s expectation for trust. The system limit of detection not only depends on the resonator’s response

to temperature, laser noise, PD and TIA noise, but also on the noise induced by the fluidic flow, mechanical vibration and the biological noise. After the oxide-open step, functionalization

of the resonator surface significantly depends on waveguide design and affinity156. The packaging and integration of the biosensor lead to the next set of challenges. Benchtop machines use

an expensive tunable laser and nanopositioners but a simple passive PIC for biosensing26. On the other hand, point-of-care devices must be compact, inexpensive, and require operation with a

low-cost tunable laser or a fixed-wavelength laser integrated with the rest of the PIC, EIC, and fluidics157,158. Current silicon photonics swept-source OCT prototypes for retinal imaging

suffer from poor sensitivity159. First, they operate at either O or C band, while ophthalmology OCT is preferred at 1050 nm for deeper penetration in the tissue. Moving to 1050 nm would

require SiN-based PICs and a tunable laser source at that wavelength. Minimizing internal reflections and improving the isolation would enhance the sensitivity. The next impediment is the

limited tuning range and sweep rate of the laser source, degrading the image acquisition rate. Finally, the laser power cannot be too high because of laser safety limitations. This, in turn,

requires a nearly lossless connection between the PIC and the imaging optics. SUMMARY AND CONCLUSION We have made big leaps in silicon photonics—from building the first high-confinement

waveguides and the very first modulators only a couple of decades ago—to a technology that has strategically leveraged materials, integration and packaging techniques from the CMOS industry

to become the dominant technology in the transceiver space. At the same time, silicon photonics is still very much a technology in development, and a gamut of possibilities, only some of

which are described in this article, signify the prospects that lie ahead. Some clear winners will emerge in the next decade and consolidation will happen. Still, the diversity of

applications will ensure ample opportunities for the technology to both scale up and spread wide. We believe that, in the next decade, we will see the likely realization of the following

milestones: * Hybrid, heterogeneous, and monolithic integration will provide the lasers, phase shifters, modulators, and electronics for LSI and even VLSI implementations with the requisite

density, configurability and programmability. Each of these integration techniques has its merits, and will likely co-exist for the foreseeable future. * Integrated lasers and SOAs on

silicon photonics will really take off. Most foundries will provide integrated lasers, with the WPE exceeding 20%. Both multi-wavelength lasers and tunable lasers will be supported. *

Silicon photonics will finally diversify beyond pluggable transceivers to other successful commercial products, finding wide adoption for CPO and xPU applications. Complex systems built

using interposers and chiplet architectures will adopt photonics for interconnects. Coherent photonics will flourish further—inside communication (even inside data centers) and sensing (FMCW

LIDAR, biosensing). * The design, modeling, simulation, fabless manufacturing, packaging, and test ecosystem will start to mature, bringing a new cohort of engineers and increased access. A

shorter fabrication turnaround will further expedite the R&D. * Plasma-dispersion-based modulators will continue to serve adequately for many WDM communication applications, but at the

same time, Pockels modulators and phase shifters will be commercialized in the SOI CMOS processes. LNOI will be integrated with silicon photonics processes for applications that require very

high-speed modulation and low _V__π_, despite their longer dimensions that prohibit LSI/VLSI integration. * Likewise, high-efficiency thermo-optical heaters will not be pushed out

overnight. But the quest for the ideal low-power phase shifter will come up with a solution that will really enable LSI/VLSI applications. Many technologies are competing, and a clear winner

is yet to emerge. * Multiple layers of SiN and Si will be commonly supported in commercial foundries, and high-performance passive components (filters, delay lines) will be optimized for

these SiN layers. * We expect the trend for inverse design to start yielding more compact, high-performance, and robust waveguide blocks that become an integral part of PDKs. The same

techniques will also fuel the performance of metamaterials and metasurfaces. * The IL, bandwidth, and on-chip area for fiber-to-PIC coupling will keep improving, with the typical IL dropping

to <0.5 dB. We also expect increased activities that open silicon photonics to a broader audience. Integrating photonic circuit design flows with (or into) electronic design automation

(EDA) environments has already started, and as circuits become more complex, the co-design of photonics and electronics will become more critical. The scaling of photonic circuits and the

convergence with electronics will also lead to greater configurability and programmability of photonic circuits, lowering the threshold for building new systems that harness the physics of

light for new applications. The space age launched the CMOS industry, the internet age launched the photonic industry, and the data age will fuel them both. DATA AVAILABILITY Data is

available on reasonable request. REFERENCES * Margalit, N. et al. Perspective on the future of silicon photonics and electronics. _Appl. Phys. Lett._ 118, 220501 (2021). Article ADS CAS

Google Scholar * Khanna, A. et al. Complexity scaling in silicon photonics. In _Optical Fiber Communication Conference and Exhibition (OFC)_, 1–3 (2017). * Soref, R. A. & Lorenzo, J. P.

Single-crystal silicon: a new material for 1.3 and 1.6 μm integrated-optical components. _Electron. Lett._ 21, 953–954 (1985). Article ADS CAS Google Scholar * Schmidtchen, J., Splett,

A., Schuppert, B., Petermann, K. & Burbach, G. Low loss singlemode optical waveguides with large cross-section in silicon-on-insulator. _Electron. Lett._ 27, 1486–1488 (1991). Article

ADS Google Scholar * Weiss, B. L., Reed, G. T., Toh, S. K., Soref, R. A. & Namavar, F. Optical waveguides in SIMOX structures. _IEEE Photonics Technol. Lett._ 3, 19–21 (1991). Article

ADS Google Scholar * Bestwick, T. ASOC—a silicon-based integrated optical manufacturing technology. In _1998 Proceedings. 48th Electronic Components and Technology Conference_, 566–571

(1998). * Liu, A. et al. A high-speed silicon optical modulator based on a metal–oxide–semiconductor capacitor. _Nature_ 427, 615–618 (2004). Article ADS CAS PubMed Google Scholar *

Liao, L. et al. High speed silicon mach-zehnder modulator. _Opt. Express_ 13, 3129–3135 (2005). Article ADS CAS PubMed Google Scholar * Liao, L. et al. 40 Gbit/s silicon optical

modulator for high-speed applications. _Electron. Lett._ 43, 1196–1197 (2007). Article ADS CAS Google Scholar * Dehlinger, G. et al. High-speed Germanium-on-SOI lateral PIN photodiodes.

_IEEE Photonics Technol. Lett._ 16, 2547–2549 (2004). Article ADS CAS Google Scholar * Ahn, D. et al. High performance, waveguide integrated Ge photodetectors. _Opt. Express_ 15,

3916–3921 (2007). Article ADS CAS PubMed Google Scholar * Vivien, L. et al. High speed and high responsivity germanium photodetector integrated in a silicon-on-insulator microwaveguide.

_Opt. Express_ 15, 9843–9848 (2007). Article ADS CAS PubMed Google Scholar * Yin, T. et al. 31 GHz Ge n-i-p waveguide photodetectors on Silicon-on-Insulator substrate. _Opt. Express_

15, 13965–13971 (2007). Article ADS CAS PubMed Google Scholar * Fang, A. W. et al. Electrically pumped hybrid AlGaInAs-silicon evanescent laser. _Opt. Express_ 14, 9203–9210 (2006).

Article ADS CAS PubMed Google Scholar * Huang, A. et al. A 10Gb/s photonic modulator and WDM MUX/DEMUX integrated with electronics in 0.13 μm SOI CMOS. In _2006 IEEE International Solid

State Circuits Conference - Digest of Technical Papers_, 922–929 (2006). * Narasimha, A., Analui, B., Liang, Y., Sleboda, T. J., Gunn, C. A fully integrated 4 × 10 Gb/s DWDM optoelectronic

transceiver in a standard 0.13 μm CMOS SOI. In _2007 IEEE International Solid-State Circuits Conference_. _Digest of Technical Paper_s, 42–586 (2007). * Dobbelaere, P. D. Silicon photonics

transceivers for hyperscale datacenters: deployment and roadmap. In _2016 European Conference on Optical Communication_ (2016). * Alduino, A. et al. Demonstration of a high speed 4-channel

integrated silicon photonics WDM link with hybrid silicon lasers. In _Integrated Photonics Research, Silicon and Nanophotonics and Photonics in Switching_, 5 (Optica Publishing Group, 2010).

* Jones, R. et al. Heterogeneously integrated InP/silicon photonics: fabricating fully functional transceivers. _IEEE Nanotechnol. Mag._ 13, 17–26 (2019). Article Google Scholar * Akhter,

M. S. et al. Wavelight: a monolithic low latency silicon-photonics communication platform for the next-generation disaggregated cloud data centers. In _2017 IEEE 25th Annual Symposium on

High-Performance Interconnects (HOTI)_, 25–28 (2017). * Wade, M. et al. An error-free 1 Tbps WDM optical I/O chiplet and multi-wavelength multi-port laser. In _Optical Fiber Communication

Conference (OFC) 2021_, 3–6 (Optica Publishing Group, 2021). * Fathololoumi, S. et al. Highly integrated 4 Tbps silicon photonic IC for compute fabric connectivity. In _2022 IEEE Symposium

on High-Performance Interconnects (HOTI)_, 1–4 (2022). * Milivojevic, B. et al. 112Gb/s DP-QPSK transmission over 2427km SSMF using small-size silicon photonic IQ modulator and low-power

CMOS driver. In _Optical Fiber Communication Conference/National Fiber Optic Engineers Conference 2013_, 1–1 (Optica Publishing Group, 2013). * Doerr, C. et al. Single-chip silicon photonics

100-Gb/s coherent transceiver. In _Optical Fiber Communication Conference: Postdeadline Papers_, 5–1 (Optica Publishing Group, 2014). * Ahmed, A. H. et al. A 6 V swing 3.6% THD > 40 GHz

driver with 4.5 × bandwidth extension for a 272 Gb/s dual-polarization 16-QAM silicon photonic transmitter. In _2019 IEEE International Solid-State Circuits Conference - (ISSCC)_, 484–486

(2019). * Iqbal, M. et al. Label-free biosensor arrays based on silicon ring resonators and high-speed optical scanning instrumentation. _IEEE J. Sel. Top. Quantum Electron._ 16, 654–661

(2010). Article ADS CAS Google Scholar * Poulton, C. V. et al. 8192-element optical phased array with 100∘ steering range and flip-chip CMOS. In _Conference on Lasers and

Electro-Optics_, 4–3 (Optica Publishing Group, 2020). * Riemensberger, J. et al. Massively parallel coherent laser ranging using a soliton microcomb. _Nature_ 581, 164–170 (2020). Article

ADS CAS PubMed Google Scholar * Zhang, X., Kwon, K., Henriksson, J., Luo, J. & Wu, M. C. Large-scale silicon photonics focal plane switch array for optical beam steering. In _Optical

Fiber Communication Conference (OFC) 2021_, 4–2 (Optica Publishing Group, 2021). * Zhang, X., Kwon, K., Henriksson, J., Luo, J. & Wu, M. C. A large-scale

microelectromechanical-systems-based silicon photonics lidar. _Nature_ 603, 253–258 (2022). Article ADS CAS PubMed PubMed Central Google Scholar * Rogers, C. et al. A universal 3D

imaging sensor on a silicon photonics platform. _Nature_ 590, 256–261 (2021). Article ADS CAS PubMed Google Scholar * Poulton, C. V. et al. Coherent lidar with an 8,192-element optical

phased array and driving laser. _IEEE J. Sel. Top. quantum Electron._ 28, 1–8 (2022). Article Google Scholar * Raval, M., Yaacobi, A. & Watts, M. R. Integrated visible light phased

array system for autostereoscopic image projection. _Opt. Lett._ 43 15, 3678–3681 (2018). Article Google Scholar * Seok, T. J., Kwon, K., Henriksson, J., Luo, J. & Wu, M. C.

Wafer-scale silicon photonic switches beyond die size limit. _Optica_ 6, 490–494 (2019). Article ADS CAS Google Scholar * Ramey, C. Silicon photonics for artificial intelligence

acceleration: Hotchips 32. In _2020 IEEE Hot Chips 32 Symposium (HCS)_, 1–26 (2020). * Huang, C. et al. A silicon photonic–electronic neural network for fibre nonlinearity compensation.

_Nat. Electron._ 4, 837–844 (2021). Article CAS Google Scholar * Shastri, B. J. et al. Photonics for artificial intelligence and neuromorphic computing. _Nat. Photonics_ 15, 102–114

(2021). Article ADS CAS Google Scholar * Bandyopadhyay, S. et al. Single chip photonic deep neural network with accelerated training. Preprint at https://arxiv.org/abs/2208.01623 (2022).

* Ashtiani, F., Geers, A. J. & Aflatouni, F. An on-chip photonic deep neural network for image classification. _Nature_ 606, 501–506 (2022). Article ADS CAS PubMed Google Scholar *

Bogaerts, W. et al. Programmable photonic circuits. _Nature_ 586, 207–216 (2020). Article ADS CAS PubMed Google Scholar * Reed, B. D. et al. Real-time dynamic single-molecule protein

sequencing on an integrated semiconductor device. _Science_ 378, 186–192 (2022). Article ADS CAS PubMed Google Scholar * Michelogiannakis, G. et al. Efficient intra-rack resource

disaggregation for HPC using co-packaged DWDM photonics. In _IEEE International Conference on Cluster Computing (CLUSTER)_, 158–172 (2023). * Pinguet, T. et al. High-volume manufacturing

platform for silicon photonics. _Proc. IEEE_ 106, 2281–2290 (2018). Article CAS Google Scholar * Bauters, J. F. et al. Silicon on ultra-low-loss waveguide photonic integration platform.

_Opt. Express_ 14, 544–555 (2013). Article ADS Google Scholar * Lindenmann, N. et al. Connecting silicon photonic circuits to multicore fibers by photonic wire bonding. _J. Light.

Technol._ 33, 755–760 (2015). Article ADS CAS Google Scholar * Cheng, L., Mao, S., Li, Z., Han, Y. & Fu, H. Y. Grating couplers on silicon photonics: design principles, emerging

trends and practical issues. _Micromachines_ 11, 666 (2020). Article PubMed PubMed Central Google Scholar * Blaicher, M. et al. Hybrid multi-chip assembly of optical communication

engines by in situ 3D nano-lithography. _Light Sci. Appl._ 9, 71 (2020). Article ADS CAS PubMed PubMed Central Google Scholar * Israel, A. et al. Photonic plug for scalable silicon

photonics packaging. in _Optical Interconnects XX,_ Vol. 11286 (eds. Schröder, H. & Chen, R. T.) 1128607 (SPIE, 2020). * Taghavi, I. et al. Polymer modulators in silicon photonics:

review and projections. _Nanophotonics_ 11, 3855–3871 (2022). Article CAS Google Scholar * Sun, J. et al. A 128 Gb/s PAM4 silicon microring modulator with integrated thermo-optic

resonance tuning. _J. Light. Technol._ 37, 110–115 (2019). Article ADS CAS Google Scholar * Yu, H. et al. Trade-off between optical modulation amplitude and modulation bandwidth of

silicon micro-ring modulators. _Opt. Express_ 22, 15178–15189 (2014). Article ADS PubMed Google Scholar * Murray, B., Antony, C., Talli, G. & Townsend, P. D. Predistortion for

high-speed lumped silicon photonic mach-zehnder modulators. _IEEE Photonics J._ 14, 1–11 (2022). Article Google Scholar * Wu, X. et al. A 20Gb/s NRZ/PAM-4 1V transmitter in 40 nm CMOS

driving a Si-photonic modulator in 0.13 μm CMOS. In _IEEE International Solid-State Circuits Conference Digest of Technical Papers_. 128–129 (2013). * Talkhooncheh, A. H. et al. A 2.4 pJ/b

100 Gb/s 3D-integrated PAM-4 optical transmitter with segmented SiP MOSCAP modulators and a 2-channel 28 nm CMOS driver. In _IEEE International Solid-State Circuits Conference (ISSCC)_, Vol.

65, 284–286 (2022). * Srinivasan, S. A. et al. 60Gb/s waveguide-coupled O-band GeSi quantum-confined Stark effect electro-absorption modulator. In _Optical Fiber Communication Conference

(OFC) 2021_, 1–3 (Optica Publishing Group, 2021). * Liang, D., Roelkens, G., Baets, R. & Bowers, J. E. Hybrid integrated platforms for silicon photonics. _Materials_ 3, 1782–1802 (2010).

Article ADS CAS PubMed Central Google Scholar * Weigel, P. O. et al. Bonded thin film lithium niobate modulator on a silicon photonics platform exceeding 100 GHz 3-dB electrical

modulation bandwidth. _Opt. Express_ 26, 23728–23739 (2018). Article ADS CAS PubMed Google Scholar * Wang, Z. et al. Silicon–lithium niobate hybrid intensity and coherent modulators

using a periodic capacitively loaded traveling-wave electrode. _ACS Photonics_ 9, 2668–2675 (2022). Article MathSciNet CAS Google Scholar * Roelkens, G. et al. Adhesive bonding of

InP/InGaAsP dies to processed silicon-on-insulator wafers using DVS-bis-Benzocyclobutene. _J. Electrochem. Soc._ 153, 1015 (2006). Article Google Scholar * Mookherjea, S., Mere, V. &

Valdez, F. Thin-film lithium niobate electro-optic modulators: to etch or not to etch. _Appl. Phys. Lett._ 122, 120501 (2023). Article ADS CAS Google Scholar * Royter, Y. et al. Dense

heterogeneous integration for InP Bi-CMOS technology. In _2009 IEEE International Conference on Indium Phosphide & Related Materials_, 105–110 (2009). * Tang, Y., Peters, J. D. &

Bowers, J. E. Over 67 GHz bandwidth hybrid silicon electroabsorption modulator with asymmetric segmented electrode for 1.3 μm transmission. _Opt. Express_ 20, 11529–11535 (2012). Article

ADS CAS PubMed Google Scholar * Han, J.-H. et al. Efficient low-loss InGaAsP/Si hybrid MOS optical modulator. _Nat. Photonics_ 11, 486–490 (2017). Article CAS Google Scholar * Hiraki,

T. et al. Integration of a high-efficiency Mach-Zehnder modulator with a DFB laser using membrane InP-based devices on a Si photonics platform. _Opt. Express_ 29, 2431–2441 (2021). Article

ADS CAS PubMed Google Scholar * Eltes, F. et al. A BaTiO3-based electro-optic pockels modulator monolithically integrated on an advanced silicon photonics platform. _J. Light.

Technol._ 37, 1456–1462 (2019). Article ADS CAS Google Scholar * Doerr, C. et al. Silicon photonics coherent transceiver in a ball-grid array package. In _2017 Optical Fiber

Communications Conference and Exhibition (OFC)_, 1–3 (2017). * Alloatti, L. et al. 100 GHz silicon–organic hybrid modulator. _Light Sci. Appl._ 3, 173–173 (2014). Article Google Scholar *

Wang, C. et al. Integrated lithium niobate electro-optic modulators operating at CMOS-compatible voltages. _Nature_ 562, 101–104 (2018). Article ADS CAS PubMed Google Scholar * Burla,

M. et al. 500 GHz plasmonic Mach-Zehnder modulator enabling sub-THz microwave photonics. _APL Photonics_ 4, 056106 (2019). Article ADS Google Scholar * Li, M. et al. Integrated pockels

laser. _Nat. Commun._ 13, 5344 (2022). Article ADS CAS PubMed PubMed Central Google Scholar * Wang, M. et al. Eight-channel laser array with 100 GHz channel spacing based on

surface-slotted structures fabricated by standard lithography. _Opt. Lett._ 43, 4867–4870 (2018). Article ADS CAS PubMed Google Scholar * Eschenbaum, C. et al. Thermally stable

Silicon-Organic Hybrid (SOH) Mach-Zehnder Modulator for 140 GBd PAM4 transmission with sub-1 V drive signals. In _2022 European Conference on Optical Communication (ECOC)_, 1–4 (2022). *

Czornomaz, L. & Abel, S. BTO-enhanced silicon photonics—a scalable PIC platform with ultra-efficient electro-optical modulation. In _2022 Optical Fiber Communications Conference and

Exhibition (FC)_, 1–3 (2022). * Xu, H. et al. Design and synthesis of chromophores with enhanced electro-optic activities in both bulk and plasmonic-organic hybrid devices. _Mater. Horiz._

9, 261–270 (2022). Article CAS PubMed Google Scholar * Eltes, F. et al. Thin-film BTO-based modulators enabling 200 Gb/s data rates with sub 1 Vpp drive signal. In _Optical Fiber

Communication Conference (OFC) 2023,_ 4–2 (Optica Publishing Group, 2023). * Al-Qadasi, M. A., Chrostowski, L., Shastri, B. J. & Shekhar, S. Scaling up silicon photonic-based

accelerators: challenges and opportunities. _APL Photonics_ 7, 020902 (2022). Article ADS CAS Google Scholar * Lu, Z., Murray, K., Jayatilleka, H. & Chrostowski, L. Michelson

interferometer thermo-optic switch on SOI with a 50 μW power consumption. _IEEE Photonics Technol. Lett._ 27, 2319–2322 (2015). Article ADS CAS Google Scholar * Iseghem, L. V. et al. Low

power optical phase shifter using liquid crystal actuation on a silicon photonics platform. _Opt. Mater. Express_ 12, 2181–2198 (2022). Article ADS Google Scholar * Notaros, M. et al.

Integrated visible-light liquid-crystal-based phase modulators. _Opt. Express_ 30, 13790–13801 (2022). Article ADS CAS PubMed Google Scholar * Izraelevitz, J. et al. Basic performance

measurements of the Intel Optane DC persistent memory module. Preprint at https://arxiv.org/abs/1903.05714 (2019). * Mukherjee, A., Saurav, K., Nair, P., Shekhar, S. & Lis, M. A case for

emerging memories in DNN accelerators. In _2021 Design, Automation & Test in Europe Conference & Exhibition (DATE)_ 938–941 (2021). * Ríos, C. et al. Ultra-compact nonvolatile phase

shifter based on electrically reprogrammable transparent phase change materials. _PhotoniX_ 3, 26 (2022). Article Google Scholar * Yang, X. et al. Non-volatile optical switch element

enabled by low-loss phase change material. _Adv. Funct. Mater._ N/A, 2304601 (2023). Article Google Scholar * Feng, Y., Thomson, D. J., Mashanovich, G. Z. & Yan, J. Performance

analysis of a silicon NOEMS device applied as an optical modulator based on a slot waveguide. _Opt. Express_ 28, 38206–38222 (2020). Article ADS CAS PubMed Google Scholar * Pruessner,

M. W. et al. Foundry-processed optomechanical photonic integrated circuits. _OSA Contin._ 4, 1215–1222 (2021). Article CAS Google Scholar * Edinger, P. et al. Silicon photonic

microelectromechanical phase shifters for scalable programmable photonics. _Opt. Lett._ 46, 5671–5674 (2021). Article ADS CAS PubMed Google Scholar * Baghdadi, R. et al. Dual slot-mode

NOEM phase shifter. _Opt. Express_ 29, 19113–19119 (2021). Article ADS CAS PubMed Google Scholar * Midolo, L., Schliesser, A. & Fiore, A. Nano-opto-electro-mechanical systems. _Nat.

Nanotechnol._ 13, 11–18 (2018). Article ADS CAS PubMed Google Scholar * Jo, G. et al. Wafer-level hermetically sealed silicon photonic MEMS. _Photon. Res._ 10, 14–21 (2022). Article

Google Scholar * Ortmann, J. E. et al. Ultra-low-power tuning in hybrid Barium Titanate-Silicon Nitride electro-optic devices on silicon. _ACS Photonics_ 6, 2677–2684 (2019). Article CAS

Google Scholar * Sorianello, V., Contestabile, G. & Romagnoli, M. Graphene on silicon modulators. _J. Light. Technol._ 38, 2782–2789 (2020). Article ADS CAS Google Scholar * Gui, Y.

et al. Monolithic PIC integrated compact GHz ITO-modulators. In _CLEO 2023_, 1–6 (Optica Publishing Group, 2023). * Nezami, M. S. et al. Packaging and interconnect considerations in

neuromorphic photonic accelerators. _IEEE J. Sel. Top. Quantum Electron._ 29, 1–11 (2023). Article MathSciNet Google Scholar * Duan, J. et al. Dynamic and nonlinear properties of

epitaxial quantum dot lasers on silicon for isolator-free integration. _Photonics Res._ 7, 1222–1228 (2019). Article CAS Google Scholar * Zhang, Y. et al. Monolithic integration of

broadband optical isolators for polarization-diverse silicon photonics. _Optica_ 6, 473–478 (2019). Article ADS CAS Google Scholar * Doerr, C. R., Chen, L. & Vermeulen, D. Silicon

photonics broadband modulation-based isolator. _Opt. Express_ 22, 4493–4498 (2014). Article ADS CAS PubMed Google Scholar * Shoman, H. et al. Stable and reduced-linewidth laser through

active cancellation of reflections without a magneto-optic isolator. _J. Light. Technol._ 39, 6215–6230 (2021). Article ADS CAS Google Scholar * Jin, W. et al. Hertz-linewidth

semiconductor lasers using CMOS-ready ultra-high-Q microresonators. _Nat. Photonics_ 15, 346–353 (2021). Article ADS CAS Google Scholar * Billah, M. R. et al. Hybrid integration of

silicon photonics circuits and InP lasers by photonic wire bonding. _Optica_ 5, 876–883 (2018). Article ADS CAS Google Scholar * Song, B., Stagarescu, C., Ristic, S., Behfar, A. &