Play all audios:

ABSTRACT CoCrMo-based metal-on-metal hip implants experienced unexpectedly high failure rates despite the high wear and corrosion resistance of the bulk material. Although they exhibit a

lower volumetric wear compared to other implant materials, CoCrMo-based implants produced a significantly larger 'number' of smaller wear particles. CoCrMo is nominally an

extremely stable material with high Cr content providing passivity. However, despite the Co:Cr ratio in the original alloy being 2:1; chemical analyses of wear particles from periprosthetic

tissue have found the particles to be composed predominately of Cr species, with only trace amounts of Co remaining. Here a correlative spectroscopy and microscopy approach has shown that

these particles dissolve via a non-stoichiometric, and geometrically inhomogeneous, mechanism similar to de-alloying. This mechanism is previously unreported for this material and was not

apparent in any of the regulatory required tests, suggesting that such tests are insufficiently discriminating. SIMILAR CONTENT BEING VIEWED BY OTHERS DRIVING ELECTROCHEMICAL CORROSION OF

IMPLANTED COCRMO METAL VIA OSCILLATORY ELECTRIC FIELDS WITHOUT MECHANICAL WEAR Article Open access 16 November 2021 TRIBO-CORROSION RESPONSE OF ADDITIVELY MANUFACTURED HIGH-ENTROPY ALLOY

Article Open access 11 June 2021 EFFECT OF PROCESSING ON MICROSTRUCTURE, MECHANICAL PROPERTIES, CORROSION AND BIOCOMPATIBILITY OF ADDITIVE MANUFACTURING TI-6AL-4V ORTHOPAEDIC IMPLANTS

Article Open access 23 April 2025 INTRODUCTION CoCrMo alloys have been used as a biomaterial for metal-on-metal (MOM) hip implants because of their high corrosion resistance and

significantly lower volumetric wear compared to metal-on-polyethylene (MOP)implants.1 This made them less likely to fail due to osteolysis (bone resorption due to an inflammatory response2,3

induced mainly by polyethylene and Ti particles and leading to the aseptic loosening of the implant), the most common hip implant failure mechanism.4 However, CoCrMo-based hip implants

suffered an unexpectedly high failure rate, with many patients experiencing unexplained pain, leading to revision surgery. Simulation studies have since revealed that, despite the lower

'volumetric' wear, CoCrMo alloys produce a much higher number of smaller wear particles: up to 'one trillion' nanoscale particles per patient annually.5 These wear

particles trigger an inflammatory immune response thought to be linked to implant failure,6 although the mechanistic details remain poorly understood. Studies on periprosthetic tissue from

failed implants have shown that CoCrMo wear particles are found inside macrophage cells.1,7,8 Widespread dissemination of metal wear debris has also been established in post-mortem studies

with particles found within macrophages and extracellularly in the synovial membrane, lymph nodes and bone marrow,9 in addition to accumulating in macrophage cells in the liver and spleen.10

A number of studies have characterised the chemical composition of particles from periprosthetic tissue, in order to understand the state of wear debris in vivo. Huber et al.11 examined

tissue from 11 cases where inflammatory reactions characteristic of immune response was evident in all. Using scanning electron microscopy–energy dispersive X-ray (SEM-EDX) and Fourier

transform infrared (FTIR) spectroscopies they reported Cr phosphate-like corrosion products, as well as un-corroded metallic particles. However, Catelas et al.12, using EDX in the

transmission electron microscope (TEM), reported Cr oxide corrosion products among the metallic particles. Addressing this difference in the reported Cr species, Hart et al.13 used

microfocus X-ray absorption spectroscopy to provide additional speciation information complementing the data on elemental composition provided by EDX. They reported the most abundant species

to be Cr-phosphate residues. Most recently, Goode et al.8 used scanning transmission X-ray microscopy- X-ray absorption spectroscopy (STXM-XAS) and scanning transmission electron

microscopy- electron energy-loss spectroscopy (STEM-EELS) combining chemical analysis at both high energy and spatial resolution. Their results confirmed the presence of debris in two

phases, a minority metallic phase (often found as the ‘core’ of reacted particle) and a more abundant Cr(III) phase with only trace amounts of oxidised Co. The reported deficiency of Co in

wear particles would indicate rapid dissolution of Co, likely into aqueous Co(II), which could then reach the blood stream and be transported away. Co dissolution raises questions from two

different perspectives: clinical and material science. Clinically, it is known that Co(II) ions are cytotoxic and genotoxic,14,15 but a second major clinical concern which remains unresolved

is the mechanism of in vivo dissolution of CoCrMo, a nominally stable material, and the speciation of Cr during this process. Cr(VI) species are known to be carcinogenic; Gill et al.

provide a comprehensive review on the clinical risks posed by Co and Cr from implant wear.16 Furthermore, whilst much attention has been given to the release of Co and Cr ions, recently

Simoes et al.17 found, in the presence of bovine serum albumin (BSA), a much higher release of Mo ions relative to Co and Cr, using inductively coupled plasma mass spectrometry (ICP-MS). The

dissolved Mo ions were thought to form complexes with proteins, thus potentially inhibiting their function. From the material science perspective, the reactivity and release of ionic

species from CoCrMo alloys is unexpected. Electrochemically, the oxidation of Co to Co(II) is restricted by passivation in CoCr alloys, which exhibit a strong ‘Cr-like’ passive behaviour

primarily due to the formation of a Cr oxide-based passive film. This passive layer is stable until high potential regions where transpassive release of the Cr(VI) ions occurs (~0.5 V vs SCE

in 0.14 M NaCl solution).18 Therefore, for continued dissolution of Co, the in vivo conditions must either allow for transpassive corrosion, or there must be a different dissolution

mechanism operating for CoCrMo 'particles'. If Cr(VI) ions were released in vivo, they may not be observed ex situ due to their transient nature. On the other hand, it is possible

that the particles’ electrochemical behaviour is different from that of the bulk and Co dissolution occurs before, or without, the release of Cr(VI). High-resolution particle analysis, as

well as in situ studies are therefore essential to confirm the behaviour of CoCrMo particles during dissolution. Understanding the failure mechanism of MOM implants is vital in order to

identify the clinical risks faced by the tens of thousands of patients who currently have such an implant.19 In addition, the findings will be essential for building new design, testing and

regulatory criteria for future biomedical implants before they attain regulatory approval. In this work ex situ and in situ electrochemical experiments were conducted in order to understand

the behaviour of CoCrMo wear particles in a simulated macrophage environment. The effect of both bovine serum albumin and an applied electric potential on this behaviour was examined. Such

electrochemical experiments have been utilised for accelerated corrosion testing of bulk alloys used in hip implants.20 In particular it is known that a key part of the immune inflammatory

response is the generation of a local oxidising environment (occurring via the production of oxygen and hydroxyl radicals from activated macrophages), which in turn leads to accelerated

corrosion.21 Therefore, by controlling the potential independently, the in vivo environment could be mimicked. The studies involved potential scans to determine the onset of dissolution. In

selected cases, a single high potential was used as an accelerated test to provide insight on later-stage dissolution. RESULTS A complementary spectroscopy and microscopy approach was used

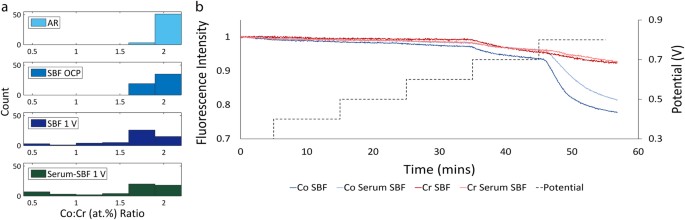

to develop an understanding of the dissolution of the particles based on chemical and morphological changes. EX SITU SPECTROSCOPY Firstly, to understand how Co:Cr ratio (at.%) varied as a

function of simulated environment, CoCrMo particles were analysed by ex situ spectroscopy using TEM-EDX. The conditions were: (i) as-received (AR); or 10 min immersion in either (ii)

simulated body fluid (SBF) at open circuit potential (OCP); (iii) SBF while being polarised at 1V; and (iv) serum-SBF while being polarised at 1V. The histograms in Fig. 1a show the

variation in Co:Cr atomic elemental ratio, across 54 particles, with each exposure condition. AR particles were composed of Co:Cr in ratios between 1.6 and 2.2. Samples exposed to SBF, at

OCP, displayed similar compositions, though a higher percentage of SBF OCP particles with ratios between 1.6–1.9 suggests the onset of limited cobalt dissolution. In clear contrast, Co:Cr

ratios of both polarised samples were spread over a large number of lower ratio bins (down to 0.4–0.7), demonstrating a greater loss of Co compared to Cr. IN SITU SPECTROSCOPY To study the

dynamics of Co and Cr dissolution from particles, in situ X-ray absorption spectroscopy (XAS) experiments were conducted at Beamline I20, Diamond Lightsource, UK. XAS was used to directly

monitor the Co and Cr elemental content of a layer of wear particles on a gold working electrode surface. The experiments were done in fluorescence geometry where the measurements were

sensitive to the wear particles and not the SBF solution. Single energy time scans were recorded above both the Co and Cr edges. Fig. 1b shows X-ray absorption data for both Co and Cr as a

function of time and potential, in SBF and serum-SBF. Each plot represents the average of three independent repeats. Changes in fluorescence intensity can be noticed at the 0.6V step but a

clear drop in the intensity (and hence the amount of each element 'remaining' in the particles) was observed for both Co and Cr at the 0.7 V and 0.8 V steps. Furthermore, the

fractional change in the amount of Co was larger compared to Cr, revealing a non-stoichiometric dissolution. In SBF, the amount of Co remaining was noticeably lower than Cr after both 0.7V

the 0.8V steps (see bar chart in ESI). In serum-SBF, the amount of Co remaining was also noticeably lower than Cr after the 0.8V step. XANES spectra acquired before and after potential

application were similar revealing no significant changes in speciation (see ESI Fig. 1). This validates the use of a single-energy scan to monitor the dissolution of Co and Cr from

particles. However, it is noted that speciation of wear particles in periprosthetic tissue showed solid Cr(III) deposits, while these results show no significant change in the oxidation

state of Cr. We hypothesise that this is a kinetic effect and the residual Cr observed would have transformed to Cr(III) species in the continued oxidising environment of the lysosome. IN

SITU MICROSCOPY The results presented above describe population-averaged measurements. To further elucidate dissolution mechanisms, these results were complemented with studies of

morphological changes in single CoCrMo particles. In situ transmission X-ray microscopy (TXM) was performed at Beamline 6–2, Stanford Synchrotron Radiation Lightsource (SSRL, USA). The TXM

images shown in Fig. 2e–g (see ESI video 1) have a spatial resolution of 30 nm and a time resolution of 3 s. An X-ray energy of 7810eV was used to provide contrast at the Co edge. No

morphological changes were observed at low potentials, however at 0.56V, changes in the particle shape can be noted, along with the rapid egress of dissolving material. To our knowledge,

this is the first time a TXM-based approach has been used to follow local dissolution behaviour. This sudden onset of morphological change is consistent with the onset of dissolution

detected during in situ spectroscopy, but provides further insights into the nature of the process. The observed “diffuse material” in these TXM images is analogous to the morphology of wear

debris observed by TEM in macrophage cells from periprosthetic tissue (Fig. 2a–d). EX SITU MICROSCOPY To obtain further insights into the morphological changes of particles under oxidising

conditions, spatially-resolved studies of the morphological changes in single CoCrMo particles were done ex situ using scanning and transmission electron microscopy (SEM and TEM). CoCrMo

particles drop-cast on to gold-coated glass slides were polarised at 0.8 V in SBF and serum-SBF. Fig. 3 shows SEM micrographs comparing an AR and SBF particles (both at OCP and also

polarised). The development of a porous surface on the polarised SBF particle can be observed in Fig. 3c. This porous surface is not as obviously visible in particles polarised in serum-SBF

(Fig. 3d) possibly due to masking of surface topography by the presence of strongly surface-adsorbed proteins.22 STEM tomography was used to reveal the sub-surface morphology of particles

polarised at 1V on a TEM grid. Fig. 3e shows a dark field STEM image of the particle after polarisation. Cross-sections through the 3D reconstruction reveal that the porosity was not only

present at the surface but also extended through the entire depth of the particle (see ESI video 2). DISCUSSION The drop of Co:Cr (at. %) ratio, observed by TEM-EDX, reveal the preferential

dissolution of Co from the alloy. However, a drop in the Co:Cr ratio only indicates the relative dissolution of the elements, while in this work the absolute loss of Co and Cr was also

directly measured independently using in situ XAS. The non-stoichiometric dissolution behaviour was particularly prominent at/above 0.7V polarisation. Additionally, the XAS results present

the Co:Cr drop averaged over a much larger population of particles (thousands compared to only 54 particles measured by TEM-EDX). They showed an approximately 22% drop in Co compared to 6%

drop in Cr at the end of the 0.8V step in SBF. This corresponds to Co:Cr ratio drop from 2 to 1.66. Although 0.7V is in the transpassive domain for this alloy, the kinetics for Cr

dissolution are slower than for Co at this potential; since there is a large effective overpotential for Co2+ dissolution. Hence the alloy dissolves non-stoichiometrically. The presence of

serum appeared to 'decrease' the amount of dissolution of Co (and to a much lesser extent, Cr) possibly due to the stabilising effects of protein adsorption on the surface.22

However, we note that this is in contrast to Mo where the presence of serum has been found to enhance dissolution.17 The evolution of the nanoporous structure is characteristic of a

dealloying-like process. Dealloying is the dissolution of the more active metal (in this case Co), leading to the aggregation of the noble component (Cr) into clusters by a process similar

to phase separation.23,24 Hence, instead of a uniform protection of the surface, aggregation of Cr atoms only passivates the surface locally. The process of dealloying is consistent with the

higher rate of Co loss compared to Cr observed in this work and in vivo. Whilst this finding suggests that ongoing Co dissolution alone is not 'necessarily' indicative of Cr(VI)

formation, we note that the onset of dissolution may require some local Cr dissolution, and so is facilitated by the onset of transpassivity. In conclusion, this work represents a

correlative approach between microscopy and spectroscopy together with a combination of ex situ and in situ studies: this multimodal approach has provided new insights into the dissolution

behaviour of CoCrMo particles. The data consistently show a significantly higher rate of dissolution of Co than Cr in oxidising conditions used here to mimic inflammatory response in vivo.

Furthermore, in situ TXM shows clear evidence of a rapid and inhomogeneous dissolution process, leading to the porous sponge-like structure observed via electron tomography. Taken together

these data suggest that the particles undergo a dealloying-like process which was not evident in studies required for the clinical approval of materials. This approach provides valuable

evidence on the likely behaviour of particles in vivo and suggests that current methods for material assessment and approval are insufficiently discriminating. METHODS CoCrMo particles were

produced by mechanical milling of the bulk standard alloy used in orthopaedic implants ASTM F75 (Co 60, Cr 30, Mo 7%). The particles were fully characterised and have been described in

detail by Simoes et al.25 Depending on the experiment, the particles were drop-cast on to one of: carbon-coated gold TEM grids, gold-coated Kapton films or gold-coated glass slides, which

acted as the working electrode. A platinum wire (Sigma-Aldrich, UK) was used as the counter electrode with an Ag/AgCl reference microelectrode, +199 mV vs SHE, (Microelectrodes Inc, USA,

against which all potentials are quoted). Simulated body fluid (SBF) at pH 5.2 was used to represent the lysosome environment in a macrophage cell, (25 mM MES buffer, 0.5 mM CaCl2.2H2O, 1 mM

MgCl2, and 200 mM KCl). In some experiments, to examine the effect of protein, 1 µg/ml of bovine serum albumin was added to the SBF (serum-SBF). In all experiments the SBF was maintained at

37 °C. IN SITU SPECTROSCOPY AT DIAMOND BEAMLINE I20 Based on a design by Kerkar et al.,26 particles on gold-coated Kapton film were attached to custom-made electrochemical cell such that

the substrate working electrode became the X-ray window in the cell. The beam size was 400 × 300 µm2 covering a population of ca.2000 particles. The cell was mounted 45° to the incident beam

and data collected in reflection geometry. In this arrangement the intensity of the fluorescence signal is directly proportional to the amount of material remaining in substrate-bound

particles; this presents a very sensitive method to measure in situ the dissolution process, as species which rapidly diffuse away from the X-ray window do not contribute to the signal.

Fluorescence intensity was monitored over time, at photon energies of 6009 and 7757 eV for Cr and Co respectively, as the potential was stepped from 0.4 to 0.8 V. Full XANES spectra were

collected at the beginning and end of the in situ experiments. IN SITU MICROSCOPY AT SSRL BEAMLINE 6-2 CoCrMo particles were imaged in situ using a 3D printed electrochemical cell (details

previously reported in ref. 27). To capture the onset of morphological changes, TXM images were collected as the potential was scanned from 0 to 0.7 V (at 0.5 mV/s). Agarose was added to the

SBF in this experiment to increase the electrolyte viscosity and hence the chance of capturing diffusing material (away from surface). DATA AVAILABILITY The data that support the findings

of this study are available from the corresponding author upon reasonable request. REFERENCES * Doorn, P. F. et al. Metal wear particle characterization from metal-on-metal total hip

replacements: transmission electron microscopy study of periprosthetic tissues and isolated particles. _J. Biomed. Mater. Res._ 42, 103–111 (1998). Article Google Scholar * Ingham, E.

& Fisher, J. The role of macrophages in osteolysis of total joint replacement. _Biomaterials_ 26, 1271–1286 (2005). Article Google Scholar * Veronesi, F., Tschon, M. & Fini, M.

Gene expression in osteolysis: review on the identification of altered molecular pathways in preclinical and clinical studies. _Int. J. Mol. Sci._ 18, 499 (2017). Article Google Scholar *

Ulrich, S. D. et al. Total hip arthroplasties: What are the reasons for revision? _Int. Orthop._ 32, 597–604 (2008). Article Google Scholar * Catelas, I. et al. Size, shape, and

composition of wear particles from metal-metal hip simulator testing: effects of alloy and number of loading cycles. _J. Biomed. Mater. Res. A_ 67, 312–327 (2003). Article Google Scholar *

Konttinen, Y. T. & Pajarinen, J. Surgery: Adverse reactions to metal-on-metal implants. _Nat. Rev. Rheumatol._ 9, 5–6 (2013). Article Google Scholar * Delaunay, C., Petit, I.,

Learmonth, I. D., Oger, P. & Vendittoli, P. A. Metal-on-metal bearings total hip arthroplasty: The cobalt and chromium ions release concern. _Orthop. Traumatol. Surg. Res._ 96, 894–904

(2010). Article Google Scholar * Goode, A. E. et al. Chemical speciation of nanoparticles surrounding metal-on-metal hips. _Chem. Commun._ 48, 8335 (2012). Article Google Scholar * Case,

C. P. et al. Widespread dissemination of metal debris from implants. _J. Bone Jt. Surg. Br._ 76, 701–712 (1994). Article Google Scholar * Urban, R. M., Tomlinson, M. J., Hall, D. J. &

Jacobs, J. J. Accumulation in liver and spleen of metal particles generated at nonbearing surfaces in hip arthroplasty. _J. Arthroplast._ 19, 94–101 (2004). Article Google Scholar *

Huber, M., Reinisch, G., Trettenhahn, G., Zweymüller, K. & Lintner, F. Presence of corrosion products and hypersensitivity-associated reactions in periprosthetic tissue after aseptic

loosening of total hip replacements with metal bearing surfaces. _Acta Biomater._ 5, 172–180 (2009). Article Google Scholar * Catelas, I., Campbell, P. A., Bobyn, J. D., Medley, J. B.

& Huk, O. L. Wear particles from metal-on-metal total hip replacements: effects of implant design and implantation time. _Proc. Inst. Mech. Eng. Part H. J. Eng. Med._ 220, 195–208

(2006). Article Google Scholar * Hart, A. J. et al. Microfocus study of metal distribution and speciation in tissue extracted from revised metal on metal hip implants. _J. Phys. Conf.

Ser._ 190, 12208 (2009). Article Google Scholar * Kwon, Y.-M. et al. Dose-dependent cytotoxicity of clinically relevant cobalt nanoparticles and ions on macrophages in vitro. _Biomed.

Mater._ 4, 25018 (2009). Article Google Scholar * Papageorgiou, I. et al. Genotoxic effects of particles of surgical cobalt chrome alloy on human cells of different age in vitro. _Mutat.

Res. - Fundam. Mol. Mech. Mutagen._ 619, 45–58 (2007). Article Google Scholar * Gill, H. S., Grammatopoulos, G., Adshead, S., Tsialogiannis, E. & Tsiridis, E. Molecular and immune

toxicity of CoCr nanoparticles in MoM hip arthroplasty. _Trends Mol. Med._ 18, 145–155 (2012). Article Google Scholar * Simoes, T. A. et al. Evidence for the dissolution of molybdenum

during tribocorrosion of CoCrMo hip implants in the presence of serum protein. _Acta Biomater._ 45, 410–418 (2016). Article Google Scholar * Hodgson, A. W. E. et al. Passive and

transpassive behaviour of CoCrMo in simulated biological solutions. _Electrochim. Acta_ 49, 2167–2178 (2004). Article Google Scholar * Bozic, K. J. et al. The Epidemiology of Revision

Total Hip Arthroplasty in the United States. _J. Bone Jt. Surg._ 91, 128–133 (2009). Article Google Scholar * Khan, M. A., Williams, R. L. & Williams, D. F. In-vitro corrosion and wear

of titanium alloys in the biological environment. _Biomaterials_ 17, 2117–2126 (1996). Article Google Scholar * Mabilleau, G. et al. Influence of fluoride, hydrogen peroxide and lactic

acid on the corrosion resistance of commercially pure titanium. _Acta Biomater._ 2, 121–129 (2006). Article Google Scholar * Valero Vidal, C. & Igual Muñoz, A. Electrochemical

characterisation of biomedical alloys for surgical implants in simulated body fluids. _Corros. Sci._ 50, 1954–1961 (2008). Article Google Scholar * Erlebacher, J., Aziz, M. J., Karma, A.,

Dimitrov, N. & Sieradzki, K. Evolution of nanoporosity in dealloying. _Nature_ 410, 450–453 (2001). Article Google Scholar * Schofield, E. J., Ingham, B., Turnbull, A., Toney, M. F.

& Ryan, M. P. Strain development in nanoporous metallic foils formed by dealloying. _Appl. Phys. Lett._ 92, 1–4 (2008). Article Google Scholar * Simoes, T. A. et al. Microstructural

characterization of low and high carbon CoCrMo alloy nanoparticles produced by mechanical milling. _J. Phys. Conf. Ser._ 522, 12059 (2014). Article Google Scholar * Kerkar, M., Robinson,

J. & Forty, aJ. In situ structural studies of the passive film on iron and iron/chromium alloys using X-ray absorption spectroscopy. _Faraday Discuss. Chem. Soc._ 89, 31–40 (1990).

Article Google Scholar * Tay, S. E. R. et al. Direct in situ observation of ZnO nucleation and growth via transmission X-ray microscopy. _Nanoscale_ 8, 1849–1853 (2016). Article Google

Scholar Download references ACKNOWLEDGEMENTS M.A.K. was supported by the EPSRC Centre for Doctoral Training in Advanced Characterisation of Materials (grant number EP/L015277/1). M.P.R.

acknowledges funding from the Royal Academy of Engineering and Shell Global Solutions via the Research Chair Scheme. We thank Diamond Light Source for access to beamline I20 (SP4843, SP9797)

that contributed to the results presented here. Use of the Stanford Synchrotron Radiation Lightsource, SLAC National Accelerator Laboratory, is supported by the U.S. Department of Energy,

Office of Science, Office of Basic Energy Sciences under Contract No. DE-AC02-76SF00515. AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * Department of Materials, Imperial College London,

London, UK Mohamed A. Koronfel, Angela E. Goode, Stephen E. R. Tay, Camilla A. Stitt, Alexandra E. Porter & Mary P. Ryan * Stanford Synchrotron Radiation Lightsource, SLAC National

Accelerator Laboratory, Menlo Park, USA Johanna Nelson Weker & Michael F. Toney * School of Chemical and Process Engineering, University of Leeds, Leeds, UK Thiago A. Simoes & Rik

Brydson * Diamond Light Source, Didcot, UK J. Frederick. W. Mosselmans & Paul Quinn * Institute of Orthopaedics and Musculoskeletal Science, Royal National Orthopaedic Hospital, London,

UK Alister Hart Authors * Mohamed A. Koronfel View author publications You can also search for this author inPubMed Google Scholar * Angela E. Goode View author publications You can also

search for this author inPubMed Google Scholar * Johanna Nelson Weker View author publications You can also search for this author inPubMed Google Scholar * Stephen E. R. Tay View author

publications You can also search for this author inPubMed Google Scholar * Camilla A. Stitt View author publications You can also search for this author inPubMed Google Scholar * Thiago A.

Simoes View author publications You can also search for this author inPubMed Google Scholar * J. Frederick. W. Mosselmans View author publications You can also search for this author

inPubMed Google Scholar * Paul Quinn View author publications You can also search for this author inPubMed Google Scholar * Rik Brydson View author publications You can also search for this

author inPubMed Google Scholar * Alister Hart View author publications You can also search for this author inPubMed Google Scholar * Michael F. Toney View author publications You can also

search for this author inPubMed Google Scholar * Alexandra E. Porter View author publications You can also search for this author inPubMed Google Scholar * Mary P. Ryan View author

publications You can also search for this author inPubMed Google Scholar CONTRIBUTIONS The work described in this paper forms part of M.A.K.’s PhD thesis; all experiments were carried out by

M.A.K. and A.E.G. The project was conceived and designed by M.P.R., A.E.P. and A.E.G. who also supervised M. A. K. during the project. Simulated wear particles were prepared and

characterised by T.S. and R.B.A.H. provided clinical insights and access to biological samples. J.N.-W. and M.F.T. co-designed the TXM (SSRL) experiments and contributed to TXM data

analysis; S. E. R. T. contributed to TXM experimental-cell design and data collection. J.F.W.M., P.Q. and C.A.S. assisted in the XAS experiments and analysis (Diamond). All authors

contributed to interpretation of the data and preparation of the manuscript. CORRESPONDING AUTHOR Correspondence to Mary P. Ryan. ETHICS DECLARATIONS COMPETING INTERESTS A.H. had research

contracts with nine orthopaedic manufacturers regarding metal on metal hip implants: Zimmer, Stryker, Depuy, Corin, Biomet, JRI, Mathys, Finsbury, Smith and Nephew. All other authors declare

no competing financial interests. ADDITIONAL INFORMATION PUBLISHER'S NOTE: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional

affiliations. ELECTRONIC SUPPLEMENTARY MATERIAL ESI FIGURE 1 ESI VIDEO 2 - STEM TOMOGRAPHY ESI VIDEO 1 - TXM IMAGES RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a

Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit

to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are

included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and

your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this

license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Koronfel, M.A., Goode, A.E., Weker, J.N. _et al._ Understanding the

reactivity of CoCrMo-implant wear particles. _npj Mater Degrad_ 2, 8 (2018). https://doi.org/10.1038/s41529-018-0029-2 Download citation * Received: 26 November 2017 * Revised: 04 January

2018 * Accepted: 18 January 2018 * Published: 12 March 2018 * DOI: https://doi.org/10.1038/s41529-018-0029-2 SHARE THIS ARTICLE Anyone you share the following link with will be able to read

this content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative