Play all audios:

ABSTRACT The effect of bolt support in mining roadways with fractured or weak surrounding rock is poor, and the roof easily loses stability. Studying the support control technology of bolts

on fractured surrounding rock is necessary. Based on the theories of pressure arches and combined arch support, the bolt anchorage and anchorage effect angle are proposed a model is

established, and the optimal bolt anchorage is calculated. The influence of related factors on the bolt anchorage and the scope of bolt action are analysed via numerical simulation and

experimental methods. The pretightening force of the bolts and the spacing between the rows of bolts are positively correlated and negatively correlated with the bolt anchorage,

respectively. The compression zone conforms to the reinforced arch state when the bolt end is anchored. The experimental work shows that the maximum spacing a of the anchor rods and the

length L of the anchor rods in the surrounding rock satisfy 4.28a < 2L < 5a. The support of fractured surrounding rock is discussed, and the concept of roof fall prevention and control

with an increasing or constant pretightening force, high surface strength and reasonable support density as the core principles is proposed. A field test of the Youzhong Coal Mine shows

that the corresponding support effect is good and that this work provides a new method for roof support of fractured surrounding rock. SIMILAR CONTENT BEING VIEWED BY OTHERS QUANTITATIVE

ANALYSIS OF THE PERFORMANCE IMPROVEMENT OF THE SURROUNDING ROCK MASS BY APPLYING A PRESTRESSED BOLT SYSTEM Article Open access 28 February 2025 ANCHORAGE PERFORMANCE OF A NEW REBAR BOLT

UNDER DIFFERENT SURROUNDING ROCK STRENGTH AND BOREHOLE DEPTH Article Open access 26 April 2024 STUDY ON INSTABILITY MECHANISM OF SOFT ROCK ROADWAY AND PRESSURE-RELIEF BOLT-GROUTING SUPPORT

TECHNOLOGY Article Open access 24 November 2023 INTRODUCTION China’s coal mine roadways are generally supported by anchor net cables1. However, with the increasing complexity of coal mining

conditions, collapses and deformations of roadway roofs and roof fall accidents occur frequently, especially in fractured surrounding rock or weak surrounding rock2. In the repair of

roadways, the density of bolt support is often increased according to experience3,4, and the strength of bolt support is enhanced5,6,7. Alternatively, when passive support methods such as

sheds are used to reinforce roofs8,9,10, and multiple roadway repairs may be needed to meet requirements11,12,13. Therefore, for the safe and reasonable support of roadway roofs in fractured

or weak surrounding rock, revealing the anchoring range of bolts in fractured or weak roof strata and studying the relationship between the scope of bolt action and the row spacing between

supports are highly important. In terms of laboratory experiments, a series of famous gravel experiments have proven the effect of anchoring on fractured surrounding rock. Lang et al.14

performed bucket tests and showed that anchor bolts form anchor reinforcement areas for gravel, constrain gravelfall, and influence the anchorage effect angle. To explain the reinforcement

effect of anchors on fractured rock masses, Hoke et al.15 proposed that anchor reinforcement areas will overlap, thus forming a large range of interaction areas within the anchoring range.

Kang et al.16 also demonstrated the overlap phenomenon of the bolt reinforcement area through numerical simulation. Wang et al.17 verified the formation mechanism of pressure arches and the

role of bolts in anchored fractured rock masses by developing a numerical simulation method for gravel anchorage experiments. In summary, the gravel experiment and related numerical

simulation methods are used to explain and confirm the existence of pressure arch in the anchored broken rock mass. However, the formation mechanism of pressure arch is not clear, and the

influencing factors of pressure arch formed by anchorage support are lack of in-depth study. The relationship between bolt support and pressure arch is not clearly explained, and the

existence of pressure arch and anchorage angle is still lack of direct evidence. Many scholars have carried out fuzzy research on the ‘reinforcement force’ or ‘anchorage stress’ generated in

the reinforcement of anchor bolts, but relatively few studies have evaluated the scope of bolt action18,19,20. Based on the roof failure of a soft rock roadway in the 150202 working face of

the Youzhong Coal Mine as the research background, this paper analyses and summarizes the causes of failure. By means of theoretical analysis, numerical simulation and experimental methods,

the bolt anchorage and anchorage effect angle are investigated, the scope of bolt action and the condition of compression zone formation are studied, and the essential relationship between

the scope of bolt action and the row spacing between supports is explored, which provides the basis for designing the row spacing between bolt supports in roadway roofs. ENGINEERING

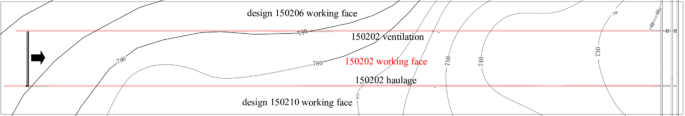

BACKGROUND ENGINEERING SITUATIONS The Youzhong Coal Mine is located in Shouyang County, Shanxi Province, China. The 150202 working face is located in the second mining area of the No. 15

coal seam. The strike length of the working face is 2110 m, the inclined length is 180 m, the thickness of the coal seam is 3.8–4.5 m, the average thickness is 4.0 m, and the burial depth is

approximately 400 m. The dip angle of the coal seam is 4–12° (the average dip angle is 8°), and the coal hardness coefficient is 0.6–1. The working face is located in the second mining

area. To the north is solid coal and the planned 150206 working face. To the south is solid coal, to the east is the ventilation downhill of the mining area, and to the west is solid coal.

The layout of the working face is shown in Fig. 1. The roof and floor rock parameters of the coal seam are shown in Fig. 2. The 150202 haulage and the ventilation were excavated along the

roof of the coal seam. The roadway sections are rectangular, 4.8 m wide and 3.8 m high. When the roadway was first supported, an anchor rod with a diameter of φ20 mm and a length of L2200 mm

was selected. The roof bolt spacing is 1000 mm, the row spacing is 1000 mm, the side bolt spacing is 1000 mm, and the row spacing is 1000 mm. The roof anchor cable adopts a φ17.8 × 6300 mm

steel strand, and the roadway roof is arranged in a 2-0-2 manner. The anchor cables are vertically arranged in the roof rock layer, with a spacing of 2.0 m and a row spacing of 2.0 m. The

roadway support schematic diagram is shown in Fig. 2. ROADWAY DEFORMATION CHARACTERISTICS The design length of the 150202 ventilation and haulage is approximately 2500 m. The roadway is

excavated along the roof. The direct roof is mudstone, the thickness is 3.6 m, and the length of the anchor rod is 2.4 m. Therefore, the anchor rod body is set in mudstone. Through field

investigation, it was found that the deformation of the surrounding rock in many roadways areas is severe and mainly manifests as large roof subsidence. The field measurements reveal that

the maximum value of roof subsidence is approximately 1.2 m and that the minimum value is approximately 0.3 m. The field deformation is shown in Fig. 3. According to the experimental tests

of the physical and mechanical parameters, the compressive strength of the roof mudstone is 20.3 MPa. The international rock mechanics community defines soft rock as rock with a uniaxial

compressive strength _σ_c between 0.5 and 25 MPa. Therefore, the mudstone above the coal seam is soft rock, and the soft rock will undergo creep deformation. Under the action of surrounding

rock extrusion, the bolt in the mudstone slips, and the bolt support fails. Moreover, under the action of tensile stress and shear force, the anchor cable slips or even deanchors, resulting

in severe overall subsidence of the roof. Second, This study revealed that when the row spacing between roof bolt supports is large, the range of bolt action has a poor control effect on the

surrounding rock, and the rock layer supported by adjacent bolts is not constrained by the bolt force. Under the action of horizontal stress and gravity, the roof mudstone seriously sinks,

and the anchor net experiences a large range of drum phenomena. DEFINITION AND THEORETICAL DERIVATION OF THE BOLT ANCHORAGE AND ANCHORAGE EFFECT ANGLE At present, among the many bolt support

design theories, reinforced arch theory and suspension theory can be used to design support parameters21,22. However, in practical applications, the thickness of the reinforced arch is

mainly judged by experience. On-site roof fall accidents occur occasionally. The determination of the range of anchoring action during bolt support and the relationship between the range of

reinforcement area formed between adjacent bolts and the spacing between rows of bolts still need to be further studied23,24,25. To further study the range of anchoring action of the bolt

and the formation of the reinforcement arch, the concept of bolt anchorage is proposed: a reinforcement arch is formed in the stress superposition area of the bolt. The angle between the

axis of the bolt and the upper and lower boundaries of the stress superposition area is called the anchorage effect angle (Fig. 4). The bolt anchorage can be used to explain the anchoring

principle of a single bolt. However, for two or more rows of bolts, the anchorage effect angle must be used to explain the anchoring principle of group anchoring. Figure 4 shows that the

anchorage effect angle _β_ is smaller than the bolt anchorage angle _α_, and its value range corresponds to the thickness _b_ of the compression zone. That is, the thicker the compression

zone, the larger the anchorage angle is, and the thinner the compression zone, the smaller the anchorage angle is. Therefore, when the distance between two adjacent bolts is large and the

superimposed area of the reinforcement zone cannot be formed, the compression zone is 0, and the anchorage effect angle _β_ is also 0. When the distance between adjacent bolts is smaller,

the formed compression zone is thicker, and the anchorage effect angle _β_ is larger. After calculation, the thickness of compression zone _b_, the length of the anchor rod _L_, the

anchorage angle of the bolt anchorage _α_ and the row distance between the anchor rods are known to have the following relationships: $$ L = \frac{b\tan \alpha + a}{{\tan \alpha }} $$ (1) $$

\alpha = arctan\frac{a}{L - b} $$ (2) where _L_ is the effective length of the bolt (m); _b_ is the thickness of the compression band (m); _α_ is the bolt anchorage (°); and _a_ is the row

spacing (m). After calculation, the thickness of compression zone b, the anchorage effect angle _β_ and the row spacing a between the anchors are known to have the following relationships:

$$ \beta = arctan\frac{2L\tan \alpha - 2a}{{2L - a\cot \alpha + a\tan \alpha }} $$ (3) In the formula, _β_ is the anchorage effect angle (°), _b_ is the thickness of the compression band

(m), _α_ is the bolt anchorage (°), and _a_ is the bolt row spacing (m). The design concepts and principles of the anchorage effect angle and the bolt anchorage. Because the formation of the

anchorage effect angle is strongly affected by the row spacing between the bolts and the thickness of the compression zone, the angle cannot be directly affected by the axial force of the

bolt in the mechanical calculation of the bolt, and the variation range of the anchorage angle is included in the variation range of the bolt anchorage. The two changes are similar.

Therefore, from the perspective of the influence of bolt anchorage on the anchoring force and the influence of bolt anchorage on the length of the bolt, the value of the optimal bolt

anchorage angle is analysed and discussed. * 1. The anchoring force _P_d of the anchor rod and the shear resistance _T_S provided by the anchor rod can be calculated according to the

Mohr–Coulomb strength criterion26 as follows: $$ T_{S} = P_{d} \cos \alpha \tan \varphi \pm P_{d} \sin \alpha $$ (4) In the formula, _P_d is the axial anchoring force of the bolt (kN); _T_S

is the antishear force provided by the bolt to the shear slip surface of the surrounding rock; _φ_ is the internal friction angle of the shear slip surface; and _α_ is the angle between the

axial force of the bolt and the transmitted stress, that is, the bolt anchorage. The change in the trigonometric function of formula (4) can be obtained: $$ T_{S} = P_{d} \frac{{\sin \left(

{\alpha \pm \varphi } \right)}}{\cos \varphi } $$ (5) In the analysis of the above formula (5), cos_φ_ is a fixed value. To obtain the maximum shear resistance, only sin (_α_ ± _φ_) can

achieve the maximum value, that is, \(\alpha = \frac{\pi }{2} \pm \varphi\). At this time, the shear resistance provided by a single bolt is the largest. * 2. Regarding the influence of bolt

anchorage on the length of the bolt. The total length of the bolt can be divided into the length of the anchorage section and the length of the free section. The length of the anchorage

Sect. 27 can be determined according to formulas (6). $$ L_{B} = \frac{{dr^{2} }}{{D^{2} - d^{2} }}L_{r} $$ (6) In the formula, _L_B anchor is the anchorage length (m); _d_r is the diameter

of the anchoring agent (mm); _L_r is the length of the anchoring agent (mm); _D_ is the borehole diameter (mm); and _d_ is the diameter of the anchor rod (mm). The length of the free section

plays a decisive role in the total length of the bolt. The minimum length of the free section is the length when the bolt is perpendicular to the shear slip surface. The relationship

between the minimum length of the bolt and the total length is: $$ L = \frac{{L_{min} }}{\cos \alpha } $$ (7) The symbols in formula (7) are consistent with those in formula (3–6). Equation

(7) shows that when \(\alpha = \frac{\pi }{2}\), the single bolt (cable) is the shortest. * 3. To obtain the best ratio of the shear resistance to the length of the bolt (cable), the bolt

anchorage can be determined by combining formulas (4) and (7), as follows: $$ \frac{{T_{S} }}{L} = \frac{{\left[ {P_{d} \cos \alpha \tan \varphi \pm P_{d} \sin \alpha } \right]\cos \alpha

}}{{L_{min} }} $$ (8) Let \(F_{\left( \alpha \right)} = \frac{{\left[ {P_{d} \cos \alpha \tan \varphi \pm P_{d} \sin \alpha } \right]\cos \alpha }}{{L_{min} }}\), and derive _F_(_α_): $$

F_{\left( \alpha \right)}^{\prime } = \frac{{P_{d} }}{{L_{min} }}\left( {\cos 2\alpha \pm \sin 2\alpha \tan \varphi } \right) $$ (9) With _α_ as the independent variable, let _F′__(α_) = 0;

then, $$ \cos 2\alpha \pm \sin 2\alpha \tan \varphi = 0 $$ (10) Then, the optimal bolt anchorage of the anchor rod is further solved as follows: $$ \alpha = \frac{\pi }{4} \pm \frac{\varphi

}{2} $$ (11) Therefore, it can be concluded that the best bolt anchorage is \(\frac{\pi }{4} \pm \frac{\varphi }{2}\). The bolt anchorage _β_ is related to the length _L_ of the bolt and the

row spacing _a_ between the bolts. It is also related to the physical and mechanical properties of the rock mass, such as the prestress _P_ of the bolt, the internal friction angle _φ_ of

the rock layer and the cohesion _C_. _L_ and a are the design parameters used to guide the design of the bolt scheme. _P_ is the applied prestress, which is an external load; however, _φ_

and _C_ are inherent properties of the strata, and these two parameters will not change with external influences. That is, the bolt anchorage is related to all the above parameters.

SIMULATION VERIFICATION OF BOLT ANCHORAGE This numerical simulation uses _FLAC__3D_ 6.0 simulation software to make corresponding numerical simulation analysis on the influencing factors of

bolt anchoring angle and anchoring angle. The size of the numerical model is designed to be 100 m × 30 m × 70 m. The rectangular mining roadway is excavated in the middle of the model. The

design width and height of the roadway are 4.5 m × 3.8 m, respectively. Considering that the in situ stress has a great influence on the stress of the bolt, the in situ stress is not applied

in the simulation process, and only the model boundary is limited28,29. In the simulation, the length of the roof bolt is 2400 mm, the bolt is divided into 12 sections; sections 9–12 are

anchorage sections, each anchorage section is 0.8 m long, sections 1– 8 are free sections, and each free section is 1.6 m long. The numerical model is shown in Fig. 5, and the mechanical

parameters of the rock materials are shown in Table 1. EVOLUTION OF BOLT ANCHORAGE UNDER SINGLE ANCHOR ACTION In this numerical simulation, a single bolt is used. The internal friction angle

of a stratum is taken as the variable, and the gradients of change are divided into 10°, 20°, 30°, 40° and 50°. As shown in Fig. 6. Figure 6 shows that as the internal friction angle

increases, the influence range of the bolt decreases continuously, and the effective carrying area also decreases accordingly. It is generally believed that the greater the internal friction

angle is, the greater the strength of the rock layer, and the smaller the influence range of the bolt action in the hard rock. Although the influence range of the bolt action in the softer

rock layer is wider than that in the harder rock layer, the effect of the bolt support increases only the influence range, does not change the thickness of the effective bearing area, and

does not improve the bearing capacity of the rock layer. Although the influence range of the bolt action in the rock layer with a larger friction angle is small, the rock mass strength is

high, the shear resistance is high, and the bearing capacity of the effective carrying area is strong. The effective carrying area here means that a single bolt can form a stress range with

bearing capacity. In the group anchor support, the reasonable anchor arrangement can make the effective carrying area of multiple anchors connected to form an effective range of action. The

stress value corresponding to the effective range of action is determined in detail in section “The interaction between the preload and compressive stress zone”. NUMERICAL SIMULATION OF THE

PRELOAD AND COMPRESSION BAND In the simulation scheme, the pretightening forces are set to 50 kN, 100 kN, 150 kN and 200 kN. The anchor bolts are arranged in a side-by-side equidistant

arrangement with a spacing of 1.0 m. Figure 7a shows that when the pretightening force is applied to the bolt, different stress distribution ranges will form in the free section and

anchoring section of the bolt, and as the pretightening force increases, the stress range increases so that the same stress range of the adjacent free section of the bolt is connected to

form an overall range with a load-bearing effect. According to the different stress values, this range can be divided into the radiation range of action, effective range and core scope of

action inward. The radiation action range refers to the maximum range of the stress of the anchor rod.The radiation action range refers to the maximum range of the stress of the anchor rod.

In this range have small stress magnitudes and cannot resist shear failure in the surrounding rock of the anchor rod. The effective range of action refers to the range of action formed by

the stress zone with a certain bearing capacity. This certain bearing capacity can prevent shear slip movement in the surrounding rock of the bolt and keep the surrounding rock stable. The

core action range refers to the area of stress concentration within the effective action range and is larger than the effective action range. This area is formed at both ends of the free

section, and the stress magnitude is greater than the that in the effective area by an order of magnitude. THE INTERACTION BETWEEN THE PRELOAD AND COMPRESSIVE STRESS ZONE In order to further

analyze the influence of preload on the stress range, when determining the boundary stress values of the three ranges, in order to obtain the accurate stress value corresponding to the

boundary, the author uses the IsoSurface command in FLAC3D 6.0 simulation to carry out the method of stress inverse boundary. By judging the boundary corresponding to multiple stress values,

it is found that when the stress value is 0.03 MPa, the displayed stress boundary can well include the radiation range. Therefore, the stress value corresponding to the boundary of the

radiation range is 0.03 MPa. Similarly, the boundary stress of the effective range and the core scope is determined to be 0.07 MPa and 0.13 MPa, respectively. As shown in Fig. 7b–e. Figure

7b–e shows that as the preload increases from 50 to 200 kN, an effective range of action is formed between the free sections of adjacent bolts, and the height and thickness of the effective

range increase so that the bearing capacity and range of the formed compression zone increase significantly. The volume of the compressive stress zone where the bolt force is greater than

0.07 MPa is calculated; that is, the volume of the effective action range is calculated. As shown in Fig. 8. According to Fig. 8, the change in volume of the effective range of action and

the prestress conform to a nonlinear relationship, the relative error is 0.9914, and the fitting effect is good. With the continuous increase in the pretightening force, the compressive

stress area also increases. These results, combined with Fig. 7, verify that with increasing pretightening force, the influence area of the bolt force increases, and the bearing capacity

within the effective range increases. The range and strength of the formed compression zone are obviously enhanced, but the pretightening force cannot be too low, nor can it increase

indefinitely. The pretightening force needs to be within a reasonable range. EVOLUTION OF THE RELATIONSHIP BETWEEN THE PRETIGHTENING FORCE AND BOLT ANCHORAGE To study the evolution of the

relationship between the pretightening force and the bolt anchorage, the above four cases are summarized. After sorting the data, a curve diagram of the change in the pretightening force and

the bolt anchorage is obtained, as shown in Fig. 9. According to Fig. 9, the relationship between the bolt anchorage and the pretightening force conforms to an exponential function, the

relative error is 0.9998, and the fitting effect is excellent. The thickness of the compression zone is related to not only the pretightening force of the bolt but also the anchorage angle

of the bolt. As the pretightening force continues to increase, the thickness of the compression zone continues to increase, and the bolt anchorage also increases. Because the internal

friction angle of the rock layer in the simulated anchoring range is 30°, the bolt anchorage always changes in the range of \(45^\circ \pm \frac{\varphi }{2}\) when the pretightening force

changes from 50 to 200 kN. RELATIONSHIPS BETWEEN ROW SPACING AND BOLT ANCHORAGE This simulation takes the row spacing between bolts as the independent variable, with bolt spacing × row

spacing configurations of 0.8 × 0.8 m, 1.0 × 1.0 m, 1.2 × 1.2 m, and 1.5 × 1.5 m. The simulation results are shown in Fig. 10. Figure 10 shows that when the row spacing is different, the

stress distribution around the bolt changes significantly. When the row spacing is 0.8 m and 1.0 m, there is some overlap of the anchoring ranges between adjacent bolts in the free section.

The overlapping part is the effective action area, which forms a compression zone and achieves the ‘group anchor’ support effect. When the row spacing between the anchors is 1.2 m and 1.5 m,

the stress range of the adjacent anchors is only in contact, and there is no compression zone between the adjacent four anchors. Each anchor alone plays a supporting role and cannot achieve

the 'group anchor' supporting effect well. INTERACTION CHARACTERISTICS BETWEEN THE BOLT SPACING AND COMPRESSIVE STRESS ZONE Figure 10b shows that the row spacing is 0.8 m, the

effective range is equal in the X–Z and Y–Z directions (approximately 220 cm), and the thickness is approximately 130 cm. The row spacing is 1.0 m, and the effective range is equal in the

X–Z and Y–Z directions; the length and thickness are approximately 240 cm and 86 cm, respectively. When the row spacing increases from 0.8 to 1.0 m, the effective area increases by 0.92 m2,

and the effective range thickness decreases by 44 cm, a decrease of approximately 34%. When the row spacing between the bolts is 1.2 m and 1.5 m, the thicknesses of the compression zone are

56 cm and 30 cm, respectively. The effective range of the adjacent bolts is only at the maximum boundary of the stress range, and no large-area overlapping of the anchoring ranges occurs.

There is no overlap of the anchoring ranges in the middle area of the four adjacent bolts. The effective range of action is the beam structure with the bolt as the node, not the overall

plate-like stress arch structure. Therefore, when the row spacing between the bolts is large, an effective range of action is formed. When the bearing capacity is limited, a complete

compression zone cannot be formed, and the support effect of the 'group anchor' is not well exerted. The volume of the compressive stress zone where the bolt force is greater than

0.15 MPa is calculated; that is, the volume of the effective action range is calculated. The calculated volume is shown in Fig. 11. Figure 11 shows that the trend of the scatter points is

strongly fitted to the polynomial curve, and the fitting effect is good. It can be seen that when the bolt spacing is greater than 1.0 m, as the bolt spacing increases, the volume of the

compressive stress zone greater than 0.15 MPa decreases sharply, indicating that when the bolt spacing is too large, the compressive stress zone that forms between the bolts arranged in

groups decreases, and the thickness of the compression zone also decreases accordingly or does not form a compression zone. INTERACTION BETWEEN BOLT SPACING AND BOLT ANCHORAGE To study the

evolution relationship between the bolt spacing and bolt anchorage angle, the above four different bolt spacing conditions are summarized, as shown in Fig. 12. According to Fig. 12, the

relationship between the bolt spacing and bolt anchorage conforms to the polynomial curve, the relative error is 0.9528, and the fitting effect is good. With increasing bolt spacing, the

thickness of the compression zone decreases, and the bolt anchorage shows a downwards trend. However, in the range of 1.3–1.5 m of bolt spacing, the anchorage angle tends to be gentle, and

the anchorage angle of the bolt is close to a constant, which is in the range of 35–36°. Because the internal friction angle of the stratum in the simulated anchoring range is 30°, the bolt

anchorage changes within the range of \(45^\circ \pm \frac{\varphi }{2}\) when the bolt spacing changes from 0.8 to 1.5 m. NUMERICAL SIMULATION OF THE BOLT ANCHORAGE MODE AND COMPRESSION

ZONE According to the ratio of anchorage length l to bolt length _L_, there are three kinds of anchorage methods: end anchorage (_l_ ≤ 1/3_L_), extended anchorage (l/3_L_ ≤ _l_ ≤ 90% _L_),

and full-length anchorage (_l_ ≥ 90% _L_). To study the influence of the three anchoring methods used on the effective range and anchorage effect angle, the anchoring method used for the

bolt is taken as the independent variable to simulate the stress range of the multirow bolt support. Three simulation schemes are determined according to the three anchoring methods, and the

schemes are shown in Table 2. The effective range of action is extracted during the simulation, and the simulation results are shown in Fig. 13. As shown in Fig. 13, when the bolt adopts

different anchoring methods, the stress distributions around the bolt exhibit obvious differences. From the end anchoring to the lengthening anchoring to the full-length anchoring, as the

length of the free section of the bolt becomes increasingly shorter, the effective range of action decreases. When the full-length anchoring is too short, the effective range of action is

insufficient. When the end of the bolt is anchored, the length of the free section is large. Combined with the top view of the effective action range, the effective stress area between the

bolts is a complete plate structure that conforms to the state of the compression zone and has a good bearing effect. When the anchor bolt is lengthened, the length of the free section

decreases. The effective range is not complete at this time. There is contact only between two adjacent anchors, and there is no overlap among the intermediate stress concentrations of the

four adjacent anchors. The effective range is a beam structure with anchors as nodes, which has a certain bearing capacity. The free section of the full-length anchoring bolt is the

shortest, accounting for 10% of the length of the bolt, and an effective range cannot be formed between adjacent bolts. It can be seen that the effective range does not form contact.

Therefore, when a full-length anchoring bolt is used, the ‘group anchor’ effect does not occur, and only the anchoring ability of the bolt itself can be exerted. Due to the short length of

the free section, the stress range formed by the bolt is limited, and the supporting effect is not as good as that of the end anchor or the lengthened anchor. When a coal mine roadway is

supported on site, end anchors are also mostly used. ANCHORAGE ANGLE EXPERIMENT OF THE BOLT Rand’s experiment14,15 shows that when the row spacing between bolts is less than three times the

average diameter of gravel, the bolt has an anchoring effect on the gravel, and has a higher bearing capacity when the anchor net is increased. This experiment is of great significance to

the study of bolt support. However, the experiment did not conduct an in-depth study on the range of anchoring effect of the bolt and its influencing factors, and did not explain the

relationship between the anchoring range of the bolt and the row spacing between the bolts. Therefore, in order to study the range of action of the bolt and its influencing factors, based on

the reference to the Rand experiment, the influence of pre-tightening force, tray size and row spacing on the range of action of the bolt is studied in depth, and the relationship between

the anchoring angle of the bolt and the row spacing is explored. EXPERIMENTAL PREPARATION Because it is difficult to measure the range of bolt action in a complete stratum, as the anchorage

angle and the range of bolt action cannot be well displayed. Therefore, the fracturing of the roadway is simulated by a group of stones in this experimental work, which can also be regarded

as a soft rock roof. In this experimental work, a fully threaded screw is used to simulate the bolt to support the gravel, a steel washer is used to simulate the bolt tray, and a hexagonal

nuts to simulate anchor nuts. By applying different pretightening forces to the full thread bolt or changing the size of the tray, the influence of the pretightening force and the size of

the tray on the action range of the bolt are studied. By changing the row spacing between bolts, the relationship between the anchorage effect angle and the row spacing is studied. The

experimental equipment is shown in Fig. 14. EFFECT OF PRETIGHTENING FORCE ON THE ANCHORING CAPACITY OF A BOLT EXPERIMENTAL SCHEME In these experiments, stones 0.5–2.0 cm in size are

selected, and the diameter of the acrylic tube and the average diameter of the stones meet the Rand experimental results. The diameter is φ6 mm, the length is 400 mm, the inner diameter of

the steel gasket is 6.2–6.4 mm, the outer diameter is 30 mm, and the thickness is 1.5 mm. Three experimental schemes are set up, and the tested preload torques are 5 N m, 7 N m and 9 N m.

EXPERIMENTAL PROCESS AND RESULTS Figure 15 shows that when the pretightening torque applied to the bolt is 5 N m and 7 N m, the stones all fall off, and the bolt does not play an anchoring

role in the gravel. When the pretightening torque is 9 N m, only a small amount of stones in the acrylic pipe falls near the lower steel washer, and most of the stones achieve a stable state

through the anchoring effect of the bolt. The experiment shows that the pretightening force affects the anchoring ability or anchoring range of the bolt. When the pretightening force is

low, the bolt cannot form an effective anchoring range and cannot restrain the stones. When the pretightening force is large, the bolt has an anchoring constraint effect on the stones so

that the stones and the bolt can form an overall supporting effect and jointly control the surrounding rock. Therefore, when the bolt support is carried out on site, it is necessary to

select an appropriate tray size, and apply a sufficient pretightening force to the bolt, so that the bolt can restrain and anchor the rock within the range of action and achieve safe and

efficient effective support. INFLUENCE OF THE TRAY SIZE ON THE ANCHORAGE CAPACITY OF THE BOLT EXPERIMENTAL SCHEME In this experimental work, stones 0.5–2.0 cm in size are selected, and the

diameter of the acrylic tube and the average diameter of the stones meet the Rand experimental results. The pretightening torque applied to the fully threaded screw with a diameter of φ6 mm

and a length of 400 mm is 9 N·m. The inner diameter of the selected steel washer is 6.4 mm, and the thickness is 1.5 mm. Four experimental schemes are set up in which the outer diameters of

the steel washers are 15 mm, 20 mm, 25 mm and 30 mm. EXPERIMENTAL PROCESS AND RESULTS Figure 16 shows that when the outer diameter of the steel washer is φ15 mm, φ20 mm and φ25 mm, all the

stones fall off, and the bolt does not play an anchoring role in the gravel. When the outer diameter of the steel washer was φ30 mm, only a small amount of stones in the acrylic pipe falls

near the lower steel washer, and most of the stones achieve a stable state through the anchoring effect of the bolt. In this experimental work, when the outer diameter of the steel washer is

30 mm, the spatial boundary formed by the falling stones near the lower steel washer is in the shape of a ‘V’. By measuring the angle of the formation of caving stones in the X–Z and Y–Z

directions, it is found that the anchoring angle of the formed anchor rod ranges from 30° to 34°. In summary, the size of the tray has an important influence on the anchoring range of the

bolt. A smaller tray can restrict the bolt’s anchoring force on the surrounding rock and thus limit the anchorage influence range. Therefore, the supporting tray should be selected when the

bolt is supported. An appropriately sized tray will form an axisymmetric V'-shaped anchoring boundary above the tray. The angle formed between the anchoring boundary and the tray is the

anchorage angle of the bolt. INFLUENCE OF THE ROW SPACING ON THE ANCHORAGE CAPACITY OF ANCHOR BOLTS EXPERIMENTAL SCHEME In this experimental work, an acrylic tube with an inner diameter of

20 cm and a height of 30 cm is selected, and stones with a size of 1.0–3.5 cm are selected. The diameter of the acrylic tube and the average diameter of the stones match the Rand

experimental results. The preload torque applied to the fully threaded screw is 9 N m, the inner diameter of the steel washer is 6.4 mm, the outer diameter is 30 cm, and the thickness is 1.5

mm. Three experimental schemes are set up with bolt spacings of 9 cm, 7 cm and 6 cm. EXPERIMENTAL PROCESS AND RESULTS Figure 17 shows that when the bolt spacing is 9 cm and 7 cm, the stones

eventually fall off. When the bolt spacing is 6 cm, only the stone near the lower washer falls under its own gravity, and the stone falls between the two washers. The bottom of the stone

has a serrated ‘W’ shape, and the remaining stones interact with each other under the action of the bolt to support the stone. The fully threaded screw is buried 30 cm in the stones, which

is equivalent to the length of the anchor rod in the surrounding rock, that is, _L_ = 30 cm. When the spacing of the fully threaded screws is 7 cm (i.e., the spacing _a_ = 7 cm), all the

stones fall, indicating that the anchoring ranges of the adjacent fully threaded screws do not overlap and that the 'group anchoring' effect is not realized. The maximum influence

range of a single fully threaded screw does not reach 7 cm. At this time, the bolt spacing a and the length _L_ of the bolt in the surrounding rock reach 4.28_a_ ≈_L_; when the spacing of

the fully threaded screws is 6 cm (i.e., the spacing _a_ = 6 cm), the stones do not fall completely, the bolt achieves the anchoring effect on the stones, and the maximum influence range of

the single bolt reaches 6 cm. In other words, when the length of the fully threaded screw in the stones is _L_ = 30 cm, the maximum lateral influence range of the single fully threaded screw

does not exceed 6 cm. At this time, the bolt spacing a and the length _L_ of the bolt in the surrounding rock satisfy _L_≈5_a_. In summary, when a bolt is used for support, an appropriate

spacing should be selected, and the maximum lateral influence range of a single bolt should not exceed the maximum spacing of the bolt. At this time, the maximum spacing _a_ of the bolt and

the length _L_ of the bolt in the surrounding rock satisfy 4.28_a_ < 2_L_ < 5_a_. When designing the bolt support spacing, the spacing should not be greater than the maximum spacing of

the bolt. DISCUSSION The above research shows that the formation of a compression zone within the anchoring range of bolts is related to the anchorage angle and the anchoring range. The

essence of fractured surrounding rock support is that the fractured rock can be anchored under the constraint of a bolt. The anchoring ranges of adjacent bolts in the anchorage structure can

overlap to realize the ‘group anchor’ effect, thus forming a compression zone with bearing capacity. Here, the author puts forward some thoughts on the stability control of fractured

surrounding rock from the perspective of the angle of anchorage effect and range of the anchoring effect of bolts and tries to determine the relationship between the angle of the anchorage

effect or range of the anchoring effect and the parameters of bolt support to clarify the concept of roof fall prevention and control of roadways by increasing or holding constant the

pretightening force, enhancing the strength of the protective surface and selecting a reasonable support density. BOLT PRETIGHTENING FORCE In the free section of the bolt, the bolt forms an

anchoring range under the action of the pretightening force. The longer the free section is, the larger the pressure arch range. However, the length of the free section cannot be increased

indefinitely, and a sufficient anchorage length should be left for the anchorage section. The above simulation and experimental research reveal that the pretightening force is an important

factor affecting the anchorage effect angle and anchoring range of the anchor rod. Therefore, in addition to improving the pretightening force, fractured surrounding rock should also adopt

measures such as anchor rod yielding to maintain a constant high pretightening force on the anchor rod and ensure that the anchorage effect angle and anchoring range of the anchor rod remain

unchanged; this ensures the bearing capacity and stability of the compression zone within the action range of the anchor rod. BOLT SUPPORT DENSITY The row spacing is one of the core

parameters of bolt support design. Many field support cases and studies have shown that30 a larger row spacing cannot form a compression zone with bearing capacity and thus cannot ensure a

better anchoring control in the fractured surrounding rock. Additionally, with a lower bolt support density prevents the anchoring ranges of adjacent bolts from overlapping, and the

'group anchor' effect cannot be realized; that is, fractured rock cannot be formed as a whole with sufficient bearing capacity. Therefore, when the surrounding rock is fractured

during the actual roadway support process, it is necessary to design a reasonable bolt support density and not use a large spacing between the rows of bolts to ensure that the anchoring

range of the bolts are in contact with each other to form a stable and load-bearing compression zone. SURFACE STRENGTH Due to the low cohesion and high degree of fragmentation, fractured

rock has more joints and fissures and greater instability31. Therefore, when supporting the surrounding rock, scientific and reasonable bolt support parameters can provide strong binding

forces in the surrounding rock, and attention should be given to enhancing the surface strength of the roadway. When supporting roadways in fractured surrounding rock or weak strata, to

prevent rock blocks outside the control range of bolts and pallets from falling and to avoid discontinuity of the transfer path of the anchoring force on the surface of roadways, it is

necessary to use high-stiffness welded steel mesh, very bending-resistant steel strips and shotcrete to enhance the constraint on the deformation of the surrounding rock, prevent the

formation of cracks in the surrounding rock at roadways, and avoid the discontinuity of key areas of anchoring stress transfer at the roadways. FIELD TEST OPTIMIZATION OF SUPPORT PARAMETERS

The roof of the 150202 haulage and ventilation in the Youzhong Coal Mine is 3.6 m thick mudstone, which is soft rock. The roadway support parameters are large, which leads to a large

deformation of the roadway. The roof separation of the roadway is large, the maximum separation is approximately 1.2 m, and the roof anchor net forms a 'net pocket'. To repair the

roadway, according to the above research, the bolt support parameters are reasonably optimized, including the row spacing between bolts, the supporting components of the protective surface

and the pretightening force of the bolts. According to the above research on the anchoring range of bolts in fractured surrounding rock or soft rock, it is concluded that the maximum spacing

a of bolts and the length _L_ of bolts in the surrounding rock need to follow 4.28a < 2_L_ < 5a. When the 150202 haulage and the ventilation are supported, the maximum row spacing

range of the bolt is calculated to be 0.8 m < _a_ < 0.93 m. Therefore, when the 150202 haulage and the ventilation are repaired, the row spacing between the roof bolts is designed to

be 0.8 m, the corresponding anchor cable spacing is designed to be 1.6 m, and the row spacing is designed to be 1.6 m. The anchor cable is arranged in a 3-0-3 manner, and the anchor mesh is

replaced by the original diamond metal mesh. The original design pretightening force of the bolt in the middle of the roadway is 70 kN, and the original design pretightening force of the

roof bolt is 90 kN. To enhance the anchoring range of the bolt and improve the strength of the bolt support, the pretightening force is increased to 100 kN. The roadway support is shown in

Fig. 18. ROADWAY DEFORMATION MONITORING Along the 150202 transport roadway and ventilation, a monitoring station for the cross-point measurement method of surrounding rock deformation is set

up every 100 m32. A roof separation instrument and pressure gauge are installed at each station. The monitoring data include the amount of separation in the deep and shallow parts of the

roof, the amount of roof subsidence, and the amount of convergence between the two sides. In the roadway, a pull-out meter is used to test the pull-out of the bolt in the roadway to

determine whether the pretightening force meets the requirements. The station layout is shown in Fig. 19. After optimizing the support of the 150202 haulage, the variation in the roof

separation instrument is measured and observed by the cross-point measurement method, and ten sets of roof separation instrument data are selected. The results are shown in Table 3. The

maximum displacement of the 7 m measuring point in the deep part of the roof is 7 mm, and the maximum displacement of the 2 m measuring point in the shallow part is 9 mm. The maximum

subsidence of the roadway roof is approximately 2–3 cm, and the overall subsidence is greatly reduced. The anchoring range is used to calculate the bolt support parameters, and the roof

support has achieved good results. The results of the on-site pull-out tests of the roof and side bolts reveal that the pretightening force applied to the bolts meets the design

requirements. CONCLUSIONS Based on pressure arch theory and combined arch support theory, this paper proposes the anchorage angle and the anchoring range of a bolt and determines the

relevant factors affecting the anchorage angle. Through numerical simulation and experimental methods, the influence of related factors on the anchorage angle, anchorage influence range or

anchorage capacity of bolts is analysed. The main conclusions are as follows: * 1. Anchorage angle and anchoring range are proposed. The best anchorage angle is \(\frac{\pi }{4} \pm

\frac{\varphi }{2}\). The range of action of the bolt is divided into the radiation range, effective range and core range. The effective range is the pressure arch area. * 2. The influences

of the pretightening force on the compressive stress zone and the anchorage angle of the bolt follow a positive nonlinear relationship and an exponential relationship. The influence of bolt

spacing on the compressive stress zone and the anchorage angle of the bolt conforms to the negative correlation of multiple curves. * 3. Different anchoring methods cause the stress

distribution around the bolt to significantly differ. There is a positive correlation between the length of the free section of the bolt and the effective range of the bolt. When the end

anchoring is used, the effective stress area formed between the bolts is a complete plate structure, which conforms to the reinforced arch state and the field situation. * 4. According to

the results of the gravel experiment, a smaller tray, a smaller pretightening force or a larger bolt spacing can prevent the bolt from forming an anchorage influence range. The maximum

transverse influence range of a single anchor rod does not exceed the maximum spacing of the anchor rod. The maximum spacing a of the anchor rods and the length L of the anchor rods in the

surrounding rock satisfy 4.28_a_ < 2_L_ < 5_a_. * 5. To address the problem of roadway support in fractured or weak strata, starting from the anchorage angle and anchoring range of

bolts, the concept of roadway roof fall prevention and control by increasing or maintaining a constant pretightening force, increasing the strength of surface protection and selecting a

reasonable supporting density as the core principles is proposed; this approach has been applied in the field, and good results have been obtained. The anchorage angle and anchoring range of

the bolt are proposed as metrics for the design of the support of fractured soft rock roadways. DATA AVAILABILITY The datasets used and/or analysed during the current study available from

the corresponding author on reasonable request. REFERENCES * Kang, H. P. Seventy years development and prospects of strata control technologies for coal mine roadways in China. _Chin. J.

Rock Mech. Eng._ 40(01), 1–30 (2021). Google Scholar * Pan, R. Study on bolt grouting mechanism and control technology of broken surrounding rock in deep roadway. _Chin. J. Rock Mech. Eng._

40(04), 864 (2021). Google Scholar * Guan, Z. C. _et al._ Reinforcement mechanics of passive bolts in conventional tunnelling. _Int. J. Rock Mech. Min. Sci._ 44(4), 625–636 (2007). Article

Google Scholar * Zhang, Y. D. _et al._ Bearing characteristic of composite rock-bolt bearing structure under different bolt support density. _J. Min. Saf. Eng._ 32(02), 305–316 (2015).

ADS Google Scholar * Wang, G. _et al._ Quasi-static laboratory testing of a new rock bolt for energy-absorbing applications. _Tunn. Undergr. Space Technol._ 38, 122–128 (2013). Article

Google Scholar * Jing, H. W. _et al._ Experimental study on the whole process of instability and failure of an chorage structure in surrounding rock of deep-buried roadway. _J. China Coal

Soc._ 45(3), 889–901 (2020). Google Scholar * Zhang, L. X. _et al._ Characteristics of surrounding rock damage and control technology of a facing-mining excavating roadway in north Shaanxi

mining area. _Sci. Rep._ 14, 5708 (2024). Article ADS CAS PubMed PubMed Central Google Scholar * Chen, D. D., Zou, J. & Chen, J. X. Research and application of the complementary

supporting technology of anchor-cable-metal-stents structure. _J. Min. Saf. Eng._ 34(03), 556–564 (2017). Google Scholar * Yao, W. _et al._ Research and development of fully enclosed

wire-shell support structure technology for deep soft rock roadway based on TRIZ theory. _Sci. Rep._ 14, 3279 (2024). Article ADS CAS PubMed PubMed Central Google Scholar * Zuo, J. P.

_et al._ Theory and technology of uniform strength support mechanics for deep coal roadway. _J. China Univ. Min. Technol._ 52(04), 625–647 (2023). Google Scholar * Yang, T. _et al._ Study

on instability mechanism of soft rock roadway and pressure-relief bolt-grouting support technology. _Sci. Rep._ 13, 20667 (2023). Article ADS CAS PubMed PubMed Central Google Scholar *

Jing, W., Zhou, J. & Yuan, L. Deformation and failure mechanism of surrounding rock in deep soft rock tunnels considering rock rheology and different strength criteria. _Rock Mech. Rock

Eng._ 57(1), 545–580 (2023). Article ADS Google Scholar * Du, X. H., Xue, J. H. & Shi, Y. Triaxial mechanical behaviour and energy conversion characteristics of deep coal bodies

under confining pressure. _Energy_ 266, 126443 (2023). Article Google Scholar * Lang, T. A. Theory and practice of rock bolting. _Trans. Am. Inst. Min. Eng._ 220, 333–348 (1960). Google

Scholar * Hoke, E. _et al._ _Underground Excavations in Rock_ (Institution of Mining and Metallurgy, 1980). Google Scholar * Kang, H. P., Jiang, T. M. & Gao, F. Q. Effect of

pretensioned stress to rock bolting. _J. China Coal Soc._ 32(7), 10–15 (2007). Google Scholar * Wang, X. _et al._ Analysis of pressure arch formation and rockbolt function in gravel

bolting. _Meitan Xuebao/J. China Coal Soc._ 46(10), 3139–3147 (2021). Google Scholar * Gu, S. C., Wang, P. & Yang, C. F. Mechanical characteristics and stability analysis of surrounding

rock reinforcement in rectangular roadway. _Sci. Rep._ 12, 22234 (2022). Article ADS PubMed PubMed Central Google Scholar * Singh, P. _et al._ Establishing the need to model the actual

state of stress along rock bolts. _Int. J. Min. Sci. Technol._ 30(3), 279–286 (2020). Article Google Scholar * Cheng, B. _et al_. Construction structure and mechanical response of

surrounding rock of composite stratum tunnel based on numerical simulation. In _2022 8th International Conference on Hydraulic and Civil Engineering: Deep Space Intelligent Development and

Utilization Forum (ICHCE), Xi’an, China_ 940–946 (2022). * Xiong, X. _et al._ Complex function solution for deformation and failure mechanism of inclined coal seam roadway. _Sci. Rep._ 12,

7147 (2022). Article ADS CAS PubMed PubMed Central Google Scholar * Hou, G. Y., Liang, J. P. & Li, X. R. Research on principles and methods of roadway support design under

conventional conditions. _Chin. J. Rock Mech. Eng._ 41(04), 691–711 (2022). Google Scholar * Yu, W. _et al._ Elastoplastic coupling analysis of surrounding rock-prestressed yielding anchor

bolts/cables based on unified strength theory. _Tunnel. Undergr. Space Technol._ 143, 105491 (2023). Article Google Scholar * Xu, Z. _et al._ A case study on new high-strength temporary

support technology of extremely soft coal seam roadway. _Sci. Rep._ 13, 21333 (2023). Article ADS CAS PubMed PubMed Central Google Scholar * Zhang, Q. _et al._ Assessment of rockburst

risk in deep mining: An improved comprehensive index method. _Nat. Resourc. Res._ 30, 1817–1834 (2021). Article ADS Google Scholar * Han, J. W. _et al._ The influence of sleeve stiffness

on anchoring force of left spiral bolt. _J. Min. Saf. Eng._ 37(05), 890–897 (2020). Google Scholar * Yao, Q. L. _et al._ Experimental study on mechanical characteristics of resin bolt

anchoring section with different anchorage lengths. _J. Min. Saf. Eng._ 36(04), 643–649 (2019). Google Scholar * Wang, J. Y. _et al._ The roof-fall mechanism and support-while-drilling

technology of the rectangular roadway with layered roofs and weak interlayers. _Processes_ 11(4), 1198 (2023). Article Google Scholar * Xie, Z. _et al._ Model experiment research on HPTL

anchoring technology for coal-rock composite roof in deep roadway. _Sci. Rep._ 13, 2381 (2023). Article ADS CAS PubMed PubMed Central Google Scholar * Shan, R. L. _et al_. Numerical

simulation study on support design of deep roadway. In _2020 5th International Conference on Materials Science, Energy Technology and Environmental Engineering_ 571 (2020). * Chen, X. _et

al._ Study on macro–micro mechanical behavior of broken rock mass using numerical tests with discrete element method. _Comp. Part. Mech._ 10, 691–705 (2023). Article Google Scholar * Hao,

J. _et al._ Analysis of mining roadway with large deformation of broken soft coal and research on supporting technology: A case study in Xin’an coal mine, China. _Eng. Fail. Anal._ 130,

105761 (2021). Article Google Scholar Download references ACKNOWLEDGEMENTS This study was funded by the Postgraduate Research & Practice Innovation Program of Jiangsu Province

(KYCX23_2803), Graduate Innovation Program of China University of Mining and Technology (2023WLKXJ041) and the Guizhou Provincial Education Department’s “Hundred Schools Thousands of

Enterprises Science and Technology Research List” Project ([2024]013). AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * State Key Laboratory for Fine Exploration and Intelligent Development of

Coal Resources, School of Mines, China University of Mining and Technology, Xuzhou, 221116, Jiangsu, China Jiyu Wang, Xigui Zheng, Xiaowei Guo, Wei Xin, Yonghui Wang, Tao Li & Longhe Liu

Authors * Jiyu Wang View author publications You can also search for this author inPubMed Google Scholar * Xigui Zheng View author publications You can also search for this author inPubMed

Google Scholar * Xiaowei Guo View author publications You can also search for this author inPubMed Google Scholar * Wei Xin View author publications You can also search for this author

inPubMed Google Scholar * Yonghui Wang View author publications You can also search for this author inPubMed Google Scholar * Tao Li View author publications You can also search for this

author inPubMed Google Scholar * Longhe Liu View author publications You can also search for this author inPubMed Google Scholar CONTRIBUTIONS J.W., and X.Z. conceived and designed the

study; J.W., W.G., W.X., and Y.W. were involved in the model experiment; J.W., T.L., and L.L. were involved in the data analysis; J.W., and X.Z. wrote the first draft of the manuscript. All

authors have read and agreed to the published version of the manuscript. CORRESPONDING AUTHOR Correspondence to Xigui Zheng. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no

competing interests. ADDITIONAL INFORMATION PUBLISHER'S NOTE Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use,

sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons

licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or

other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in

the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the

copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Wang, J., Zheng, X.,

Guo, X. _et al._ Study on the anchorage mechanism and roof stability control technology of bolts in fractured or weak surrounding rock. _Sci Rep_ 14, 22906 (2024).

https://doi.org/10.1038/s41598-024-67811-2 Download citation * Received: 28 April 2024 * Accepted: 16 July 2024 * Published: 02 October 2024 * DOI: https://doi.org/10.1038/s41598-024-67811-2

SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy

to clipboard Provided by the Springer Nature SharedIt content-sharing initiative KEYWORDS * Fractured surrounding rock * Roof abscission layer * Bolt anchorage * Anchorage effect angle *

Bolt spacing * Roof support