Play all audios:

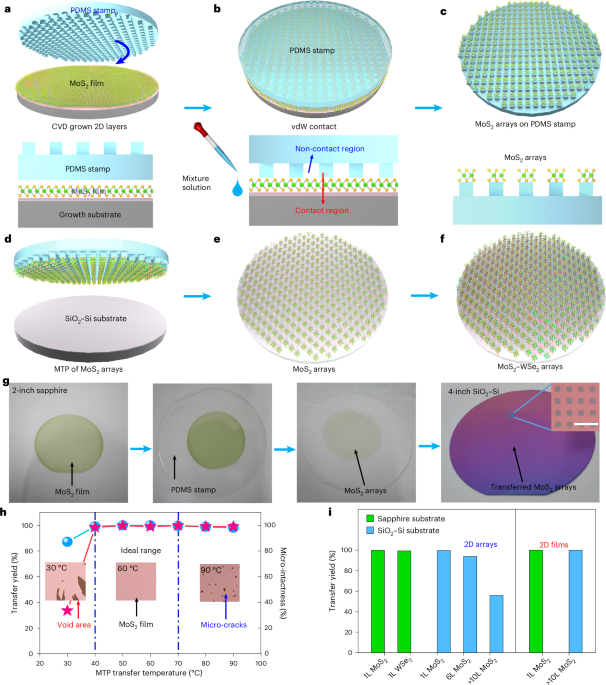

ABSTRACT The large-area transfer of two-dimensional (2D) materials from their growth substrate is crucial for electronic device integration. However, it is easy to damage sub-1-nm thick

materials, and existing transfer methods typically involve a trade-off in terms of lateral size, quality and accuracy. Here we report a mass transfer printing technology that uses a

polydimethylsiloxane stamp patterned with precisely arranged micro-posts to gently transfer wafer-level 2D arrays and to stack van der Waals heterostructure arrays. After the stamp is

brought into contact with the 2D material, an ethanol–water solution is added, which penetrates the 2D material–growth substrate interface between the non-contact regions of the stamp and

causes the film to delaminate. We use the approach to transfer a 2-inch (~5 cm) monolayer molybdenum disulfide film containing more than 1,000,000 arrays with lateral dimensions of 20 × 20

µm2, a density of 62,500 arrays per cm2 and a yield of 99% in a single operation. Integrated 2D transistors with different device architectures created with the technology show a device

yield of around 97.9% (back gate) and nearly damage-free electrical properties (top and bottom gate). We also develop a capillary force-assisted transfer model to explain the rapid transfer

mechanism. Access through your institution Buy or subscribe This is a preview of subscription content, access via your institution ACCESS OPTIONS Access through your institution Access

Nature and 54 other Nature Portfolio journals Get Nature+, our best-value online-access subscription $32.99 / 30 days cancel any time Learn more Subscribe to this journal Receive 12 digital

issues and online access to articles $119.00 per year only $9.92 per issue Learn more Buy this article * Purchase on SpringerLink * Instant access to full article PDF Buy now Prices may be

subject to local taxes which are calculated during checkout ADDITIONAL ACCESS OPTIONS: * Log in * Learn about institutional subscriptions * Read our FAQs * Contact customer support SIMILAR

CONTENT BEING VIEWED BY OTHERS WAFER-SCALE INTEGRATION OF TRANSITION METAL DICHALCOGENIDE FIELD-EFFECT TRANSISTORS USING ADHESION LITHOGRAPHY Article 21 December 2022 HIGHLY REPRODUCIBLE VAN

DER WAALS INTEGRATION OF TWO-DIMENSIONAL ELECTRONICS ON THE WAFER SCALE Article 20 March 2023 AUTOMATED PROCESSING AND TRANSFER OF TWO-DIMENSIONAL MATERIALS WITH ROBOTICS Article 23 May

2025 DATA AVAILABILITY Source data are provided with this paper. All other data that support the findings of this study are available from the corresponding authors upon reasonable request.

REFERENCES * Radisavljevic, B. et al. Single-layer MoS2 transistors. _Nat. Nanotechnol._ 6, 147–150 (2011). Google Scholar * Radisavljevic, B. & Kis, A. Mobility engineering and a

metal–insulator transition in monolayer MoS2. _Nat. Mater._ 12, 815–820 (2013). MATH Google Scholar * Ghatak, S., Pal, A. N. & Ghosh, A. Nature of electronic states in atomically thin

MoS2 field-effect transistors. _ACS Nano_ 5, 7707–7712 (2011). MATH Google Scholar * Liu, L. et al. Van der Waals bipolar junction transistor using vertically stacked two‐dimensional

atomic crystals. _Adv. Funct. Mater._ 29, 1807893 (2019). Google Scholar * Shen, P. C. et al. Ultralow contact resistance between semimetal and monolayer semiconductors. _Nature_ 593,

211–217 (2021). MATH Google Scholar * Wang, Y. et al. Van der Waals contacts between three-dimensional metals and two-dimensional semiconductors. _Nature_ 568, 70–74 (2019). MATH Google

Scholar * Liu, L. et al. Uniform nucleation and epitaxy of bilayer molybdenum disulfide on sapphire. _Nature_ 605, 69–75 (2022). MATH Google Scholar * Li, L. et al. Epitaxy of wafer-scale

single-crystal MoS2 monolayer via buffer layer control. _Nat. Commun._ 15, 1825 (2024). MATH Google Scholar * Liu, L. et al. Transferred van der Waals metal electrodes for sub-1-nm MoS2

vertical transistors. _Nat. Electron._ 4, 342–347 (2021). MATH Google Scholar * Wu, F. et al. Vertical MoS2 transistors with sub-1-nm gate lengths. _Nature_ 603, 259–264 (2022). MATH

Google Scholar * Chen, X. et al. Wafer-scale functional circuits based on two dimensional semiconductors with fabrication optimized by machine learning. _Nat. Commun._ 12, 5953 (2021). MATH

Google Scholar * Smets, Q. et al. Scaling of double-gated WS2 FETs to sub-5nm physical gate length fabricated in a 300 mm FAB. _IEEE IEDM_ 21, 725–728 (2021). Google Scholar * Li, N. et

al. Large-scale flexible and transparent electronics based on monolayer molybdenum disulfide field-effect transistors. _Nat. Electron._ 3, 711–717 (2020). MATH Google Scholar * Hong, S. et

al. Highly sensitive active pixel image sensor array driven by large-area bilayer MoS2 transistor circuitry. _Nat. Commun._ 12, 3559 (2021). MATH Google Scholar * Dodda, A. et al. Active

pixel sensor matrix based on monolayer MoS2 phototransistor array. _Nat. Mater._ 21, 1379–1387 (2022). MATH Google Scholar * Park, Y. J. et al. All MoS2-based large area, skin-attachable

active-matrix tactile sensor. _ACS Nano_ 13, 3023–3030 (2019). MATH Google Scholar * Jang, H. et al. An atomically thin optoelectronic machine vision processor. _Adv. Mater._ 32, 2002431

(2020). Google Scholar * Meng, W. et al. Three-dimensional monolithic micro-LED display driven by atomically thin transistor matrix. _Nat. Nanotechnol._ 16, 1231–1236 (2021). MATH Google

Scholar * Kwon, H. et al. Monolayer MoS2 field-effect transistors patterned by photolithography for active matrix pixels in organic light-emitting diodes. _npj 2D Mater. Appl._ 3, 9 (2019).

Google Scholar * Hwangbo, S. et al. Wafer-scale monolithic integration of full-colour micro-LED display using MoS2 transistor. _Nat. Nanotechnol._ 17, 500–506 (2022). MATH Google Scholar

* Yu, H. et al. Wafer-scale growth and transfer of highly-oriented monolayer MoS2 continuous films. _ACS Nano_ 11, 12001–12007 (2017). MATH Google Scholar * Yang, P. et al. Batch

production of 6-inch uniform monolayer molybdenum disulfide catalyzed by sodium in glass. _Nat. Commun._ 9, 979 (2018). MATH Google Scholar * Gong, Y., Zhang, X., Redwing, J. M. &

Jackson, T. N. Thin film transistors using wafer-scale low-temperature MOCVD WSe2. _J. Electron. Mater._ 45, 6280–6284 (2016). Google Scholar * Chen, T. A. et al. Wafer-scale single-crystal

hexagonal boron nitride monolayers on Cu (111). _Nature_ 579, 219–223 (2020). MATH Google Scholar * Asselberghs, I. et al. Wafer-scale integration of double gated WS2-transistors in 300

mm Si CMOS fab. In _Proc. 2020 IEEE International Electron Devices Meeting (IEDM)_ 40.2.1–40.2.4 (IEEE, 2020). * Fan, S. et al. Transfer assembly for two-dimensional van der Waals

heterostructures. _2D Mater._ 7, 022005 (2020). Google Scholar * Ma, X. et al. Capillary-force-assisted clean-stamp transfer of two-dimensional materials. _Nano Lett._ 17, 6961–6967 (2017).

MATH Google Scholar * Das, S. et al. Transistors based on two-dimensional materials for future integrated circuits. _Nat. Electron._ 4, 786–799 (2021). MATH Google Scholar * Quellmalz,

A. et al. Large-area integration of two-dimensional materials and their heterostructures by wafer bonding. _Nat. Commun._ 12, 917 (2021). MATH Google Scholar * Phommahaxay, A. et al. The

growing application field of laser debonding: from advanced packaging to future nanoelectronics. In _Proc. 2019 IEEE International Wafer Level Packaging Conference (IWLPC)_ 1–8 (IEEE, 2019).

* Xin, H. et al. A review on high throughput roll-to-roll manufacturing of chemical vapor deposition graphene. _Appl. Phys. Rev._ 5, 031105 (2018). Google Scholar * Carlson, A. et al.

Transfer printing techniques for materials assembly and micro/nanodevice fabrication. _Adv. Mater._ 24, 5284–5318 (2012). MATH Google Scholar * Bower, C. A. et al. Micro-transfer-printing:

heterogeneous integration of microscale semiconductor devices using elastomer stamps. In _Proc. 2014 IEEE SENSORS_ 2111–2113 (IEEE, 2014). * Cui, X. et al. Rolling up transition metal

dichalcogenide nanoscrolls via one drop of ethanol. _Nat. Commun._ 9, 1301 (2018). MATH Google Scholar * Kang, M. A. et al. Fabrication of flexible optoelectronic devices based on

MoS2/graphene hybrid patterns by a soft lithographic patterning method. _Carbon_ 116, 167–173 (2017). MATH Google Scholar * Mannix, A. J. et al. Robotic four-dimensional pixel assembly of

van der Waals solids. _Nat. Nanotechnol._ 17, 361–366 (2022). MATH Google Scholar * Reynolds, M. F. et al. MoS2 pixel arrays for real-time photoluminescence imaging of redox molecules.

_Sci. Adv._ 5, eaat9476 (2019). MATH Google Scholar * Li, H. et al. From bulk to monolayer MoS2: evolution of Raman scattering. _Adv. Funct. Mater._ 22, 1385–1390 (2012). MATH Google

Scholar * Wang, Y. et al. Electrochemical delamination of CVD-grown graphene film: toward the recyclable use of copper catalyst. _ACS Nano_ 5, 9927–9933 (2011). MATH Google Scholar *

Biscay, F., Ghoufi, A. & Malfreyt, P. Surface tension of water–alcohol mixtures from Monte Carlo simulations. _J. Chem. Phys_ 134, 044709 (2011). Google Scholar * Heim, L. O. et al.

Measurement of line tension on droplets in the submicrometer range. _Langmuir_ 29, 14147–14153 (2013). MATH Google Scholar * Behroozi, F. A fresh look at the Young-Laplace equation and its

many applications in hydrostatics. _Phys. Teach._ 60, 358–361 (2022). MATH Google Scholar * Vargaftik, N. B., Volkov, B. N. & Voljak, L. D. International tables of the surface tension

of water. _J. Phys. Chem. Ref. Data_ 12, 817–820 (1983). MATH Google Scholar * Vazquez, G., Alvarez, E. & Navaza, J. M. Surface tension of alcohol water + water from 20 to 50 °C. _J.

Chem. Eng. Data_ 40, 611–614 (1995). MATH Google Scholar * Nakatani, M. et al. Ready-to-transfer two-dimensional materials using tunable adhesive force tapes. _Nat. Electron._ 7, 119–130

(2024). Google Scholar * Shim, J. et al. Controlled crack propagation for atomic precision handling of wafer-scale two-dimensional materials. _Science_ 362, 665–670 (2018). MATH Google

Scholar * Satterthwaite, P. F. et al. Van der Waals device integration beyond the limits of van der Waals forces using adhesive matrix transfer. _Nat. Electron._ 7, 17–28 (2024). MATH

Google Scholar * Liu, H. et al. Controlled adhesion of ice—toward ultraclean 2D materials. _Adv. Mater._ 35, 2210503 (2023). Google Scholar * Gao, X. et al. Integrated wafer-scale

ultra-flat graphene by gradient surface energy modulation. _Nat. Commun._ 13, 5410 (2022). MATH Google Scholar * Yang, X. et al. Highly reproducible van der Waals integration of

two-dimensional electronics on the wafer scale. _Nat. Nanotechnol._ 18, 471–478 (2023). MATH Google Scholar * Vu, Q. A. et al. Near-zero hysteresis and near-ideal subthreshold swing in

h-BN encapsulated single-layer MoS2 field-effect transistors. _2D Mater._ 5, 031001 (2018). MATH Google Scholar * Huang, J. K. et al. High-κ perovskite membranes as insulators for

two-dimensional transistors. _Nature_ 605, 262–267 (2022). MATH Google Scholar * Illarionov, Y. Y. et al. Ultrathin calcium fluoride insulators for two-dimensional field-effect

transistors. _Nat. Electron._ 2, 230–235 (2019). MATH Google Scholar * Li, W. et al. Uniform and ultrathin high-κ gate dielectrics for two-dimensional electronic devices. _Nat. Electron._

2, 563–571 (2019). MATH Google Scholar * Li, T. et al. A native oxide high-κ gate dielectric for two-dimensional electronics. _Nat. Electron._ 3, 473–478 (2020). MATH Google Scholar *

Cho, K. et al. Electric stress-induced threshold voltage instability of multilayer MoS2 field effect transistors. _ACS Nano_ 7, 7751–7758 (2013). MATH Google Scholar Download references

ACKNOWLEDGEMENTS This work was supported by the State Key Research and Development Program of China (grant no. 2022YFB3603902) and National Natural Science Foundation of China (grant no.

62004042). We acknowledge N. Sheng Xu and S. Deng for the valuable advice on thesis writing. AUTHOR INFORMATION Author notes * These authors contributed equally: Liwei Liu, Zhenggang Cai.

AUTHORS AND AFFILIATIONS * Frontier Institute of Chip and System, Fudan University, Shanghai, China Liwei Liu * State Key Laboratory of ASIC and System, School of Microelectronics, Fudan

University, Shanghai, China Zhenggang Cai, Siwei Xue, Sifan Chen, Saifei Gou, Zhejia Zhang, Yiming Guo, Yusheng Yao, Wenzhong Bao & Peng Zhou * State Key Laboratory of Photovoltaic

Science and Technology, Shanghai Frontiers Science Research Base of Intelligent Optoelectronic and Perception, Institute of Optoelectronic and Department of Material Science, Fudan

University, Shanghai, China Hai Huang Authors * Liwei Liu View author publications You can also search for this author inPubMed Google Scholar * Zhenggang Cai View author publications You

can also search for this author inPubMed Google Scholar * Siwei Xue View author publications You can also search for this author inPubMed Google Scholar * Hai Huang View author publications

You can also search for this author inPubMed Google Scholar * Sifan Chen View author publications You can also search for this author inPubMed Google Scholar * Saifei Gou View author

publications You can also search for this author inPubMed Google Scholar * Zhejia Zhang View author publications You can also search for this author inPubMed Google Scholar * Yiming Guo View

author publications You can also search for this author inPubMed Google Scholar * Yusheng Yao View author publications You can also search for this author inPubMed Google Scholar * Wenzhong

Bao View author publications You can also search for this author inPubMed Google Scholar * Peng Zhou View author publications You can also search for this author inPubMed Google Scholar

CONTRIBUTIONS L.L. and P.Z. conceived the idea and initiated the present study. L.L., Z.C. and S.X. carried out the experiments and analysed the data. S.C., H.H., S.G., Y.G. and Z.Z. helped

fabricate the MoS2-FETs arrays. Y.Y. assisted in performing the Raman spectroscopy tests. L.L. wrote the paper. W.B. and P. Z. contributed to discussions and paper revision. CORRESPONDING

AUTHORS Correspondence to Liwei Liu, Wenzhong Bao or Peng Zhou. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing interests. PEER REVIEW PEER REVIEW INFORMATION

_Nature Electronics_ thanks Jiayang Wu, Cheng-Yan Xu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. ADDITIONAL INFORMATION PUBLISHER’S NOTE

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. SUPPLEMENTARY INFORMATION SUPPLEMENTARY INFORMATION Supplementary Figs.

1–36 and Table 1. SUPPLEMENTARY VIDEO 1 Transferred MoS2 arrays. SUPPLEMENTARY VIDEO 2 Transfer of 2D film. SUPPLEMENTARY VIDEO 3 Mixture solution penetrates along the non-contact regions

rapidly. SOURCE DATA SOURCE DATA FIG. 1 Statistical source data from Fig. 1h,i. SOURCE DATA FIG. 2 Statistical source data from Fig. 2q–s. SOURCE DATA FIG. 4 Statistical source data from

Fig. 4b,c,e,f,h,i. SOURCE DATA FIG. 5 Statistical source data from Fig. 5c,d. RIGHTS AND PERMISSIONS Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights

to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the

terms of such publishing agreement and applicable law. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Liu, L., Cai, Z., Xue, S. _et al._ A mass transfer technology for

high-density two-dimensional device integration. _Nat Electron_ 8, 135–146 (2025). https://doi.org/10.1038/s41928-024-01306-w Download citation * Received: 18 January 2024 * Accepted: 07

November 2024 * Published: 06 January 2025 * Issue Date: February 2025 * DOI: https://doi.org/10.1038/s41928-024-01306-w SHARE THIS ARTICLE Anyone you share the following link with will be

able to read this content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing

initiative