Play all audios:

ABSTRACT In the orthognathic surgery, dental splints are important and necessary to help the surgeon reposition the maxilla or mandible. However, the traditional methods of manual design of

dental splints are difficult and time-consuming. The research on computer-aided design software for dental splints is rarely reported. Our purpose is to develop a novel special software

named EasySplint to design the dental splints conveniently and efficiently. The design can be divided into two steps, which are the generation of initial splint base and the Boolean

operation between it and the maxilla-mandibular model. The initial splint base is formed by ruled surfaces reconstructed using the manually picked points. Then, a method to accomplish

Boolean operation based on the distance filed of two meshes is proposed. The interference elimination can be conducted on the basis of marching cubes algorithm and Boolean operation. The

accuracy of the dental splint can be guaranteed since the original mesh is utilized to form the result surface. Using EasySplint, the dental splints can be designed in about 10 minutes and

saved as a stereo lithography (STL) file for 3D printing in clinical applications. Three phantom experiments were conducted and the efficiency of our method was demonstrated. SIMILAR CONTENT

BEING VIEWED BY OTHERS ACCURACY OF A SURFACE-BASED FUSION METHOD WHEN INTEGRATING DIGITAL MODELS AND THE CONE BEAM COMPUTED TOMOGRAPHY SCANS WITH METAL ARTIFACTS Article Open access 16 May

2022 A DIGITAL WORKFLOW FOR PAIR MATCHING OF MAXILLARY ANTERIOR TEETH USING A 3D SEGMENTATION TECHNIQUE FOR ESTHETIC IMPLANT RESTORATIONS Article Open access 23 August 2022 IN-VITRO ACCURACY

OF THE VIRTUAL PATIENT MODEL WITH MAXILLOMANDIBULAR RELATIONSHIP AT CENTRIC OCCLUSION USING 3D-PRINTED CUSTOMIZED TRANSFER KEY Article Open access 31 January 2025 INTRODUCTION Orthognathic

surgery procedures are mainly adopted to correct skeletal angle class II and III deformities, dent maxillofacial deformities, mandibular laterognathia, and maxillofacial asymmetries1,2,3,4.

Computer-aided design has been gaining popularity in orthognathic surgery for enhancing the surgical treatment procedures and outcomes. Previous studies have demonstrated that computer-aided

design and manufacturing (CAD/CAM) technology can improve the treatment5,6,7,8. For example, Lin _et al_.9 proposed a method for producing customized positioning guides combined with the

single-splint technique for orthognathic surgery. Zinser and Zöller10 developed and patented a CAD/CAM technique for the fabrication of multiple surgical splints for orthognathic surgery.

Schouman _et al_.11 carried out a cadaveric study to evaluate the accuracy of the CAD/CAM generated splints in orthognathic surgery by comparing planned with post-operative 3D images. The

study demonstrated that maxillary repositioning can be accurately approximated and predicted by specific computational planning and CAD/CAM generated splints in orthognathic surgery.

Nimeskern presented a new web service based on software solution to obtain surgical splints for orthognathic surgery12. Obviously, the CAD softwares play a critical role in computer assisted

orthognathic surgery. Nowadays, the softwares utilized in some studies for the generation of the splint are listed as below13,14,15: * 1 Simplant OMS 10.1 (Materialise®, Leuven, Belgium). *

2 Unigraphics NX 7.5 (Siemens PLM Software, TX, USA). * 3 Maxilim 2.2.2 (Medicim NV, Mechelen, Belgium). However, the softwares mentioned above are commercial and the involved algorithms

are not reported. Especially, as some of them are general CAD softwares, the process for splint generation is always time consuming and complicated. Therefore, the development of robust

methods to support the design of the splints is of utmost importance. In this study, a novel software named EasySplint for the design of the splint has been developed. Compared with the

traditional softwares, an easier and more efficient approach to design the splint is adopted in EasySplint. The customized splint with specific shape can be achieved on the basis of the

Boolean operation between the initial splint and maxilla-mandibular model, and the interference elimination. METHODS OVERVIEW The architecture of the software is divided into the following

four modules: * 1 The module for preprocessing: The CT data of a patient can be imported into EasySplint to reconstruct the maxilla and mandibular models based on image segmentation, region

growing and marching cubes algorithm. These two models can be repositioned according to clinical requirement. * 2 The module for generation of the initial splint base: An array of points on

the maxilla and mandibular model are manually selected. The positions and normals of these points are then utilized to generate lines, whose nodes then can be used to reconstruct ruled

surfaces. The initial splint base is formed by appending the ruled surfaces. In addition, the positions and normals can be adjusted to better form the splint. * 3 The module for Boolean

operation: The type of Boolean operation here is the difference between initial splint model and maxilla-mandibular model. The algorithm of our Boolean operation is to split the intersected

mesh, then to assemble related mesh to form the final dental splint. * 4 The module for interference elimination: This module aims at removing the undercut that might exist in the splint.

The user can specify the position, direction and distance of the interference elimination. Specified planes are utilized to cut the model on the specific direction. Based on the contour of

the cutting, 3D images can be generated under the principle that the upper layer should contain the geometry information of the lower layer. A model then can be reconstructed from the image

data by applying the Marching Cube (MC) algorithm16. Finally, a Boolean operation between the splint with undercuts and the model is used to eliminate the interference. The core modules of

EasySplint are the generation of the splint base, Boolean Operation and interference elimination. THE GENERATION OF THE INITIAL SPLINT The design of the initial splint aims to construct a

model with customized shape and size. The generation approach is based on the ruled surface reconstruction. Ruled surface reconstruction is one of the most efficient methods to form a

surface for two non-collinear lines. The input of our algorithm is the user-chosen point data. There are two main steps in the generation of the initial splint. The first step is to use the

user-chosen point to generate a line with a certain length and direction. The line’s position, length and normal can be adjusted manually to ensure the initial splint’s shape and size. The

lines are shown in Fig. 1. The second step is to use the lines’ nodes to reconstruct the ruled surfaces. Two lists (up list and down list) are used to store the lines which are generated by

the points picked from maxilla model and mandibular model. The data structure can be shown as follow: Line Structure { double normal; double inner_point[3]; double outside_point[3];

double inner_length[3]; double outside_length[3]; } Every two points from the up list and every two points from the down list can form a ruled surface, which is shown in Fig. 2. By this

mean, a number of ruled surfaces are able to be reconstructed and appended as the initial splint. In order to make the shape of the splint smoother, we firstly interpolate the points into

parametric splines and then sample enough points to reconstruct the ruled surface. The general frame of the generation of initial splint can be show in Fig. 3. THE BOOLEAN OPERATION A

Boolean operation is used to define a third model C by computing model A and model B. There are three common Boolean operations, which are union, intersection and difference. The Boolean

operation used in the EasySplint is difference, between the initial splint and the maxilla-mandibular model. The algorithm of Boolean operation is based on some vtk classes, and can be

divided into three main steps, which is shown in Fig. 4 and can be described as follow: * 1 Split meshes: the main part of Boolean operation algorithm is to identify the intersection

surfaces between two surface meshes. * 2 Calculate the signed distance field: the distance from points in one surface to another surface is calculated. The distance is defined as the

distance between the point of one surface and the nearest point of the other surface. If the point is inside the space bounded by the mesh, then the distance is negative. In other words, if

the point is outside the mesh, then the distance is positive. * 3 Extract the specified surfaces: with the signed distance field, cells of the surface with certain value of the distance can

be extracted. The Boolean operation difference can be defined as the cells of model A whose points are non-negative distance from model B combined with the cells of model B whose points are

non-positive distances from A. THE INTERFERENCE ELIMINATION As the splint is generated based on the shape of the maxilla-mandibular model, undercut may exist in the splint when the teeth of

the patient are big-end-up. On that condition, the splint won’t fit the patient as the existence of the interference between the teeth and the splint. A novel method is proposed to eliminate

the interference. The main idea of the algorithm is based on 3D reconstruction and Boolean operation. A temporary model is reconstructed based on a 3D points volume firstly, which is

created according to the space information when the original model moving along the specified direction for interference elimination. Then Boolean operation between the temporary model and

the splint is applied to eliminate the part of the splint which causes the interference. As the Boolean operation has already been discussed above, this section will mainly focus on how to

reconstruct the temporary model. Marching Cubes algorithm (MC algorithm) is adopted to accomplish the reconstruction of the model. The main steps can be described as the generation of the

contour, the construction of the image data, the image data processing and the surface reconstruction. The typical structure which will cause interference is cone. A cone with big-end-up is

used as the original model to illustrate the method works, which is shown in Fig. 5. The standard model in Fig. 6(a) is a surface model designed using the software of SolidWorks with the

exact radius of the first contour cut by the plane. The comparison between the standard model and the reconstructed one was evaluated by computing the distance errors of these two models,

and the result of color map is shown in Fig. 6(b). The mean distance error is calculated to be 0.365 mm, which is precise enough in clinical application14. The details of the method for

measurements are described in the second step of the subsection of “Boolean operation”. The first step is to generate the contour of the model. The contour contains the information of the

space extend of the model moving along the direction of the undercut removal. A plane is used to cut the model to get the contour, and then enough points are sampled inside the contour. By

offsetting the cutting plane, an array of contours of the model can be acquired. Based on the principle that the upper layer should contain the geometry information of the lower layer, we

append the upper layer contour and lower lay contour to form a volume of points. The second step is to map the point volume into a 3D image data. The size of the point volume will be

calculated firstly in order to define a 3D image data. Based on the points from the volume, the correspondent position of the 3D image data will be assigned a non-zero scalar value, whereas

other positions’ scale value will be zero. Image dilation and image erosion are applied in the xyz direction to improve the quality of the 3D image data. Then the temporary model will be

reconstructed with the MC algorithm based on the 3D image data. RESULTS A general framework of the splint design was introduced and several algorithms including the ruled surface generation,

Boolean operation and interference elimination were presented. On the basis of these algorithms, a software named EasySplint was developed under the platform of Microsoft Visual Studio 2010

(Microsoft, Washington, USA). Some famous open source toolkits including VTK (Visualization Toolkit, an open-source, freely available software system for 3D computer graphics, image

processing and visualization, http://www.vtk.org/) and Qt (a cross-platform application and UI framework, http://qt-project.org/) were involved. Several cases of customized splint design for

the orthognathic surgery were conducted using EasySplint. With the manually drawn points indicating the lines with a specified direction and length, the splint can be generated

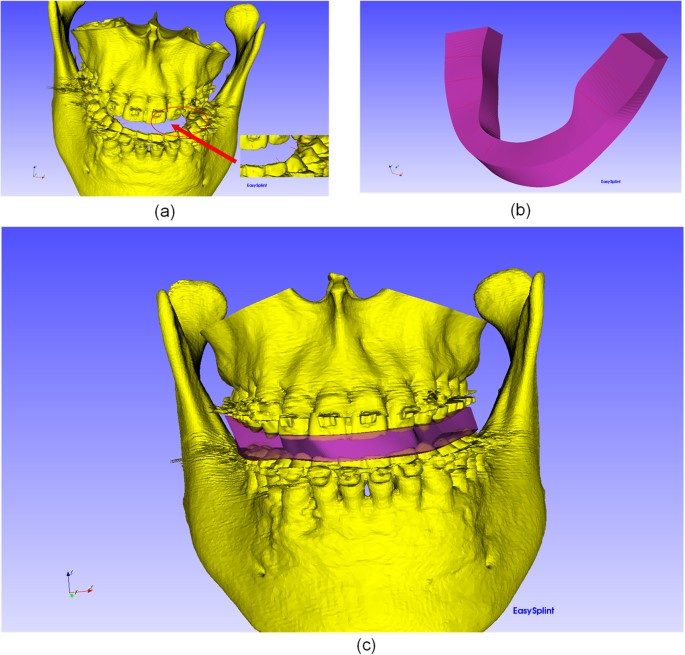

automatically and rapidly. If the maxilla-mandibular model has some big-end-up parts, the interference elimination can be conducted. Three phantom experiments were conducted, of which two

were for the orthognathic surgery and one is for the orthognathic postoperative opening-mouth training shown in Fig. 7. The fabricated splint of one case shown in Fig. 8 demonstrated the

designed splint can fit the maxilla-mandibular model well. All the phantom experiments were conducted on a PC with Intel Core i7-4710MQ with a 2.50 GHz CPU, 8 GB memory and a 64-bit Windows

8 operating system. Table 1 shows the property of the input maxilla and mandibular model and the corresponding computing time of each step during the design of the splint. In this table,

time of the generation of the splint is the sum of ‘Lines adjustment’, ‘Generation of the initial splint’, and ‘The Boolean operation’. For all examples, the overall time for the design of

the splint is about 10 minutes. In terms of accuracy, we made comparison study on the splint design between our method and commercial softwares. Previously, clinical experiments of the

dental splints designed with commercial softwares, such as ProPlan CMF, Unigraphics NX, VisCAM, etc., were conducted and reported by our research group17. It shows that the difference

between the planned and the actual bony surgical movement at the edge of the upper central incisor was 0.50 ± 0.22 mm in sagittal, 0.57 ± 0.35 mm in vertical, and 0.38 ± 0.35 mm in

horizontal direction (midlines) for 15 patients. Then, on the basis of the same data, the dental splints were designed using EasySplint, and the distance errors between these two kinds of

splints were computed and the color map is shown in Fig. 9. The results show that there was no difference between them in the occlusal area of the dentition, which means that the accuracy of

the splint designed using EasySplint can be guaranteed as same as that of using commercial softwares. Nevertheless, it will be further validated with clinical experiments in the future

study. DISCUSSION The commercial softwares are not specially developed for dental splint design, so the procedures for dental splint design tend to be complicated. Take 3-matic

(Materialise®, Leuven, Belgium), one of the most commonly adopted softwares for template design, as an example: the time-consuming workflow of dental splint design is shown in Fig. 10 and it

usually takes 0.5~1 hour to accomplish the whole design procedure. Other commercial softwares, such as Imageware, UG, Pro/E, ProPlan CMF etc. are even more complicated, and the data import

and export among them are inevitable due to that the functions of each software are limited and the whole design can only be accomplished through the combination of those softwares. It also

means it requires high level of the engineering background for the user to grasp all of those softwares and get very familiar with the interface among them. The rate limiting steps for the

design time in those softwares are complicated manual operations of geometry design including combining surfaces, repairing and de-featuring, remeshing, modifying and editing, etc. The

EasySplint software can provide an easy and efficient approach to design a customized splint for orthognathic surgery based on the 3D maxilla-mandibular model of the patient. The shape and

position of the initial splint is planned by user’s specified points. By applying the Boolean operation between the initial splint and the maxilla-mandibular model, the final splint is

produced automatically. The interference elimination has been taken consideration based on a novel method using the Marching Cubes algorithm. The conducted phantom experiments indicate that

the splints designed by the EasySplint software are suitable for the orthognathic surgery or the open-mouth exercising. As shown in the Table 1, the time of the splint design is about 10

minutes whereas it need 30~60 minutes using the traditional softwares. Currently, the Easy Splint software is just in a preliminary stage and some functions will be improved in the future

work. Firstly, if there are artifacts in the original CT images, the 3D-reconstructed maxilla- mandibular model will not be accurate enough for the splint design. Under this condition, we

will use laser scanning technology to obtain the precise dentition data of the cast model, and then register the CT data and the laser-scanned data using the method we described in the ref.

18. Secondly, the sharpness of edges of the splint hasn’t been taken consideration in EasySplint. Since the splint with shape edges may injure the soft tissue of the patient in orthognathic

surgery, or cause uncomfortable feeling for the patient in postoperative opening-mouth training, how to fillet the splint still need further study. Thirdly, if the size of the original model

for interference elimination is too large, the operating system will not be able to allocate enough memory. In this case, we will develop a novel 3D reconstruction and mesh decimation

algorithms to decrease the error and improve the quality of the temporary model for interference elimination. Furthermore, clinical applications will be conducted in the near future to

demonstrate its feasibility and reliability. ADDITIONAL INFORMATION HOW TO CITE THIS ARTICLE: Chen, X. _et al_. Development of a computer-aided design software for dental splint in

orthognathic surgery. _Sci. Rep._ 6, 38867; doi: 10.1038/srep38867 (2016). PUBLISHER'S NOTE: Springer Nature remains neutral with regard to jurisdictional claims in published maps and

institutional affiliations. REFERENCES * Ow, A. & Cheung, L. K. Skeletal stability and complications of bilateral sagittal split osteotomies and mandibular distraction osteogenesis: an

evidence-based review. J Oral Maxillofac Surg. 67, 2344–2353 (2009). Article Google Scholar * Ruiz, L. P. & Lara J. C. Facial nerve palsy following bilateral sagittal split ramus

osteotomy for setback of the mandible. Int J Oral Maxillofac Surg. 40, 884–886 (2011). Article Google Scholar * Chrcanovic, B. R. & Custódio, A. L. Optic, oculomotor, abducens, and

facial nerve palsies after combined maxillary and mandibular osteotomy: case report. J Oral Maxillofac Surg, 69, 234–241 (2011). Article Google Scholar * Rai, K. K., Shivakumar, H. R.

& Sonar, M. D. Transient facial nerve palsy following bilateral sagittal split ramus osteotomy for setback of the mandible: a review of incidence and management. J Oral Maxillofac Surg.

66, 373–378 (2008). Article Google Scholar * Choi, J. Y., Song, K. G. & Baek, S. H. Virtual model surgery and wafer fabrication for orthognathic surgery. Int J Oral Maxillofac Surg.

38, 1306–1310 (2009). Article Google Scholar * Xia, J. J., Gateno, J. & Teichgraeber, J. F. Three-dimensional computeraided surgical simulation formaxillofacial surgery. Atlas Oral

Maxillofac Surg Clin North Am. 13, 25–39 (2005). Article Google Scholar * Schendel, S. A. & Montgomery, K. A Web-based, integrated simulation system for craniofacial surgical planning.

Plast Reconstr Surg. 123, 1099–1106 (2009). Article CAS Google Scholar * Sun, Y. et al. Accuracy of upper jaw positioning with intermediate splint fabrication after virtual planning in

bimaxillary orthognathic surgery. J Craniofac Surg. 24, 1871–1876 (2013). Article Google Scholar * Lin, H. H., Chang, H. W. & Lo, L. J. Development of customized positioning guides

using computer-aided design and manufacturing technology for orthognathic surgery. International Journal of Computer Assisted Radiology and Surgery, 10, 2021–2033 (2015). Article Google

Scholar * Zinser, M. J. & Zöller, J. E. Method for production of at least one surgical splint, in particular for computer assisted maxillofacial operations and transposition

osteotomies. _European Journal of Patents_, Oct. 31 (2010). * Schouman, T. et al. Accuracy evaluation of CAD/CAM generated splints in orthognathic surgery: a cadaveric study. Head & Face

Medicine. 11, 1–9 (2015). Article Google Scholar * Nimeskern, N. Hybrid Mix - a new software solution and web service to get surgical splints in orthognathic surgery. Head and Face

Medicine. 10, O12 (2014). Article Google Scholar * Samir, A. H. C. & Federico, H. A. 3D planning in orthognathic surgery: CAD/CAM surgical splints and prediction of the soft and hard

tissues results - our experience in 16 cases. Journal of cranio-maxillo-facial surgery: official publication of the European Association for Cranio-Maxillo-Facial Surgery. 40, 162–168

(2012). Article Google Scholar * Li, B. et al. A novel method of computer aided orthognathic surgery using individual CAD/CAM templates: a combination of osteotomy and repositioning

guides. British Journal of Oral & Maxillofacial Surgery. 51, 239–244 (2013). Article Google Scholar * Swennen, G. R. J., Mollemans, W. & Schutyser, F. Three-dimensional treatment

planning of orthognathic surgery in the era of virtual imaging. J Oral Maxillofac Surg. 67, 2080–2092 (2009). Article Google Scholar * Lorensen, W. E. & Cline, H. E. Marching Cubes: A

High Resolution 3D Surface Construction Algorithm. Computer Graphics. 21, 163–169 (1987). Article Google Scholar * Sun, Y. et al. Accuracy of upper jaw positioning with intermediate splint

fabrication after virtual planning in bimaxillary orthognathic surgery. J Craniofac. Surg. 24, 1871–1876 (2013). Article Google Scholar * Chen, X. J., Yuan, J. B., Lin, Y. P., Wang, C. T.

& Huang, Y. L. Computer-aided preoperative planning and surgical templates in implant dentistry for the cases involving metal artifacts. _Proceedings of the 10th IEEE International

Conference on Information Technology and Applications in Biomedicine (ITAB 2010_). Nov. 2010. Download references ACKNOWLEDGEMENTS This work was supported by Natural Science Foundation of

China (Grant No.: 81511130089), Foundation of Science and Technology Commission of Shanghai Municipality (Grant No.: 14441901002, 15510722200, and 16441908400) and SJTU - KU Leuven Fund.

AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * Institute of Biomedical Manufacturing and Life Quality Engineering, State Key Laboratory of Mechanical System and Vibration, School of

Mechanical Engineering, Shanghai Jiao Tong University, Shanghai, China Xiaojun Chen, Xing Li & Lu Xu * Department of Imaging and Pathology, OMFS IMPATH Research Group, Faculty of

Medicine, KU Leuven, Leuven, Belgium Yi Sun & Constantinus Politis * Department of Oral and Maxillofacial Surgery, University Hospitals Leuven, Leuven, Belgium Yi Sun & Constantinus

Politis * Faculty of Computer Science and Biomedical Engineering, Institute for Computer Graphics and Vision, Graz University of Technology, Graz, Austria Jan Egger * BioTechMed-Graz, Graz,

Austria Jan Egger Authors * Xiaojun Chen View author publications You can also search for this author inPubMed Google Scholar * Xing Li View author publications You can also search for this

author inPubMed Google Scholar * Lu Xu View author publications You can also search for this author inPubMed Google Scholar * Yi Sun View author publications You can also search for this

author inPubMed Google Scholar * Constantinus Politis View author publications You can also search for this author inPubMed Google Scholar * Jan Egger View author publications You can also

search for this author inPubMed Google Scholar CONTRIBUTIONS X.C. and X.L. conceived of the project, and designed the framework of the software. X.C., X.L., and J.E. proposed the new

algorithms, developed the software and performed the experiments. X.C., X.L., L.X. Y.S., C.P., and J.E. wrote the paper. All authors discussed the results and commented on the manuscript.

ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing financial interests. RIGHTS AND PERMISSIONS This work is licensed under a Creative Commons Attribution 4.0

International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the

material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit

http://creativecommons.org/licenses/by/4.0/ Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Chen, X., Li, X., Xu, L. _et al._ Development of a computer-aided design software

for dental splint in orthognathic surgery. _Sci Rep_ 6, 38867 (2016). https://doi.org/10.1038/srep38867 Download citation * Received: 26 April 2016 * Accepted: 14 November 2016 * Published:

14 December 2016 * DOI: https://doi.org/10.1038/srep38867 SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a shareable

link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative