Play all audios:

Access through your institution Buy or subscribe The researchers — who are based at various institutions in China and Germany — start with a CVD-grown diamond membrane on a silicon substrate

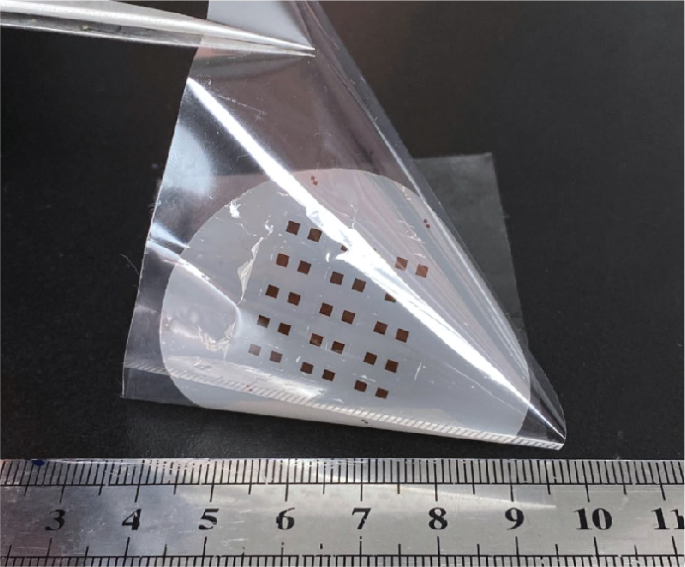

and crop the wafer edge. Using the exposed diamond–substrate edge, the membrane could then be exfoliated using Scotch tape and a peeling machine. The method can create diamond membranes up

to 2 inches wide and with an average roughness of the bottom surface under 1 nm. These were then transferred to polydimethylsiloxane substrates to make flexible diamond strain sensors, which

could withstand 10,000 cycles at 2% strain. ORIGINAL REFERENCE: _Nature_ 636, 627–634 (2024) This is a preview of subscription content, access via your institution ACCESS OPTIONS Access

through your institution Access Nature and 54 other Nature Portfolio journals Get Nature+, our best-value online-access subscription $29.99 / 30 days cancel any time Learn more Subscribe to

this journal Receive 12 digital issues and online access to articles $119.00 per year only $9.92 per issue Learn more Buy this article * Purchase on SpringerLink * Instant access to full

article PDF Buy now Prices may be subject to local taxes which are calculated during checkout ADDITIONAL ACCESS OPTIONS: * Log in * Learn about institutional subscriptions * Read our FAQs *

Contact customer support AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * Nature Electronics https://www.nature.com/natelectron/ Matthew Parker Authors * Matthew Parker View author publications

You can also search for this author inPubMed Google Scholar CORRESPONDING AUTHOR Correspondence to Matthew Parker. RIGHTS AND PERMISSIONS Reprints and permissions ABOUT THIS ARTICLE CITE

THIS ARTICLE Parker, M. Making diamonds with sticky tape. _Nat Electron_ 8, 9 (2025). https://doi.org/10.1038/s41928-025-01343-z Download citation * Published: 27 January 2025 * Issue Date:

January 2025 * DOI: https://doi.org/10.1038/s41928-025-01343-z SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a

shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative