Play all audios:

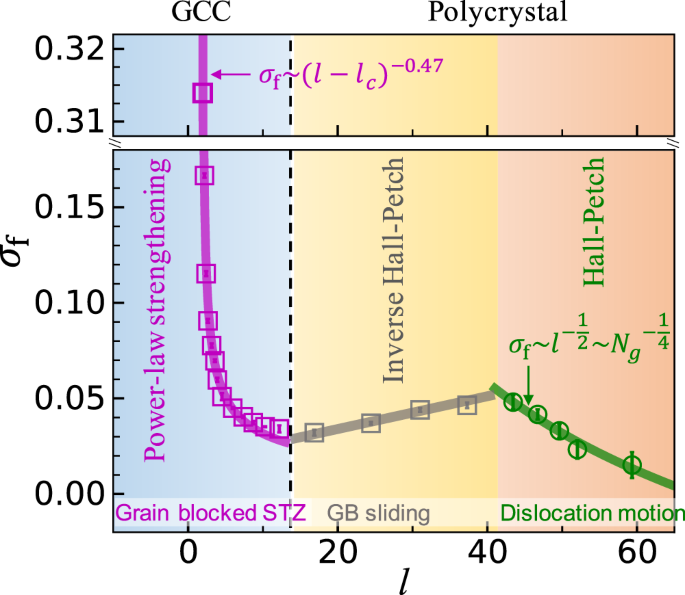

ABSTRACT The strength of polycrystal increases as the grain diameter _l_ decreases, i.e. the Hall–Petch behaviour. This trend reverses at about 3 < _l_ < 15 nm, i.e. the

inverse-Hall–Petch behaviour. How the grain size affects material’s strength at _l_ < 3 nm (~12 particles) remains unclear. Here our simulations use mixtures of soft and hard particles so

that compression can continuously reduce _l_ to merely a few particles, resulting in ultrafine-grained solids termed as glass-crystal composites. Beyond the conventional Hall–Petch

strengthening and inverse-Hall–Petch softening, we observe a power-law strengthening at _l_ < 14 particles as a result of the blockage of shear-banding by crystalline grains. Amorphous

and crystalline regions accommodate shear strains via bond-breaking and collective rotation, respectively. Moreover, a polycrystal–glass transition occurs at _l_ = 14 particles featured with

peaks of various quantities, which deepens the understanding on softening–strengthening transition. SIMILAR CONTENT BEING VIEWED BY OTHERS SUBSTANTIALLY ENHANCED HOMOGENEOUS PLASTIC FLOW IN

HIERARCHICALLY NANODOMAINED AMORPHOUS ALLOYS Article Open access 20 June 2023 HIGH-PRESSURE ANNEALING DRIVEN NANOCRYSTAL FORMATION IN ZR50CU40AL10 METALLIC GLASS AND STRENGTH INCREASE

Article Open access 07 August 2020 TOUGHENING OXIDE GLASSES THROUGH PARACRYSTALLIZATION Article 07 August 2023 INTRODUCTION Polycrystals are usually deformed via dislocation motion and grain

boundary (GB) sliding. The former dominates when GB density is low, and the latter dominates in fine-grained polycrystals. Consequently, the flow stress _σ_f increases as the mean grain

diameter _l_ decreases for large-grained polycrystals because GBs impede the dislocation-mediated plasticity. This Hall–Petch behaviour1,2,3 gives way to inverse Hall–Petch behaviour when

grain size is reduced to around 10–15 nm, where the GB sliding dominates the plasticity and softens the materials4,5. Recently, GBs are stabilised through relaxation and segregation6 or

through high pressure7 so that the inverse Hall–Petch softening effect is staved off, and the Hall–Petch behaviour can extend to 3 nm7. However, the effect of grain diameter on material

strength at _l_ < 3 nm has been rarely explored because ultrafine-grained polycrystals are usually unstable and undergo grain coarsening8. We expect that the inverse Hall–Petch

softening4,5,6,9 breaks down, and a Hall–Petch-like strengthening restores in the ultrafine-grained regime (Fig. 1) because polycrystals will become amorphous solids (i.e. glasses) when

grains are small enough9,10 and glasses usually exhibit higher strength than their polycrystalline counterparts11,12,13. In contrast to polycrystal whose plasticity is controlled by

dislocation motion (Hall–Petch) or GB sliding (inverse Hall–Petch)4, glass deforms and flows in the form of nanoscale shear band14,15,16, which is due to the propagation of localised shear

transformation zones (STZs)17,18,19. To search for the expected strengthening regime and investigate its mechanism, solids with ultrafine crystalline grains are needed. In recent years,

nanocrystallites embedded in an amorphous matrix have attracted considerable interest because these materials possess advantages of both polycrystal and glass. For example, such structure

can produce ultrahigh strength20 and world-record fatigue resistance21 and thereby shows promising applications21,22. These materials are known as the dual-phase glass-crystal structure20 or

nanocomposite21, and lack of a standard terminology. Here, we call them glass-crystal composites (GCCs). How the grain size affects the strength of such material and whether the inverse

Hall–Petch softening gives way to a strengthening behaviour in ultrafine-grained materials remain unclear. Polycrystals and GCCs with mean grain diameter _l_ < 3 nm are difficult to

fabricate. In the previous study, we found that the grain size of a polycrystal composed of hard and soft particles (Fig. 2a–c) can be continuously reduced to a few particles by compression

(Fig. 2d and Supplementary Figs. 1 and 2)10. This system provides an ideal platform to study whether the inverse Hall–Petch strengthening breaks down and a Hall–Petch-like strengthening

restores in the finer-grained regime. The microstructure change in solids is difficult to resolve in situ because of the fast dynamics and localised nature of STZs11,15,23, and thus it has

primarily been studied by simulations24,25. Here, we perform the event-driven molecular dynamics simulation26 on binary mixtures of hard and soft particles in two dimensions (see details in

“Methods”) for which the continuously tunable grain size has been achieved10. The system is compressed from a single crystal to polycrystals and to GCCs with continuously decreasing of _l_

(Supplementary Figs. 1, 2c), which enables us to study the strength of the ultrafine-grained regime and its microstructure change and mechanism. The grain diameter is usually in unit of

particle number in simulations and nanometer in experiments. The diameter of a typical metallic atom, e.g. Cu or Ni4,7, is about 0.25 nm. The measured stress–strain curves at different

packing fraction _ϕ_ and mixing ratio _x_, the flow stress _σ_f and shear modulus _K_ as a function of crystalline grain size all show not only the conventional Hall–Petch strengthening and

inverse-Hall–Petch softening, but also a power-law strengthening in the ultrafine-grained regime. The mechanisms of the mechanical behaviours are analysed from the microstructural

deformations upon shear. The observed softening–hardening transition in Fig. 1 coincides with the polycrystal–glass transition identified in the previous work10. RESULTS STRUCTURES OF THE

GCCS The area fraction _ϕ_ increases with pressure (see “Methods” and Supplementary Fig. 2a). At _ϕ_ = 0.62, a random mixture of soft and hard particles with the mixing ratio _x_: (1 − _x_)

forms a single crystal (Supplementary Fig. 1) because their sizes are the same. As pressure increases, more soft particles are compressed and more size mismatches are produced, which leads

to amorphisation (Fig. 2d, e) with the reduced crystallinity _X_ (Fig. 2f) and grain size _N_g (Fig. 2g, h). _X_ is the fraction of crystalline particles, and _N_g is the mean number of

particles per crystalline grain (see the definition in “Methods”). Figure 2e shows that hard particles are highly apt to participate in crystalline grains. For systems with large _x_, less

hard particles are available for grain formation, thereby decreasing the crystallinity (Fig. 2f). The crystalline order of particle _i_ is characterised by its bond-orientational order

parameter _ψ_6_i_ (see details in “Methods”). ∣_ψ_6_i_∣ = 1 for a perfect hexagonal lattice and is close to zero for a disordered structure. As _ϕ_ increases (i.e. the grain size decreases

in Fig. 2h), 〈∣_ψ_6∣〉 gradually decreases for hard particles but maintains constant for soft particles (Fig. 2i), demonstrating that the structure primarily changes near hard particles. For

binary systems, the chemical short-range order (SRO) is characterised by the Warren-Cowley parameter27,28 $${\alpha

}_{{{{{{{{\rm{AB}}}}}}}}}=1-\frac{{Z}_{{{{{{{{\rm{AB}}}}}}}}}}{{x}_{{{{{{{{\rm{B}}}}}}}}}{Z}_{{{{{{{{\rm{A}}}}}}}}}},$$ (1) where _Z_A is the coordination number of A-type particle; _Z_AB is

the number of B-type particles neighbouring surrounding A, and _x_B is the fraction of B-type particles. _α_AB = 0, >0 and <0 correspond to random mixture, favoured, and unflavoured

AB bonds, respectively. Δ_α_ of four types of bonds relative to the values at _ϕ_ = 0.79 (Fig. 2j) show that the same type particles have a higher affinity, which increases with _ϕ_. This

demixing in binary solid can enhance the local packing efficiency29 and result in a stable GCC. MECHANICAL BEHAVIOURS The stress-strain curves at different _ϕ_ in Fig. 3a exhibit a linear

increase (i.e. elastic regime) at strain _γ_ < 0.025 (Supplementary Fig. 3), a nonlinear increase (i.e. strain-hardening) at 0.025 < _γ_ < 0.2, and a plateau (i.e. steady flow) at

_γ_ > 0.2. The plateau height, which refers to the flow stress _σ_f, increases as the grain size decreases at _N_g < 170, i.e. \(l\simeq \sqrt{170}\simeq 14\) particles. This behaviour

is qualitatively different from the inverse Hall–Petch behaviour, and can neither be fitted by the Hall–Petch relationship1,2 (Fig. 3b). Instead, _σ_f(_N_g) satisfies a power law, $${\sigma

}_{{{{{{{{\rm{f}}}}}}}}}({N}_{{{{{{{{\rm{g}}}}}}}}})\propto {({N}_{{{{{{{{\rm{g}}}}}}}}}-{N}_{{{{{{{{\rm{g1}}}}}}}}})}^{-{\eta }_{1}}$$ (2) with the fitted _η_1 = 0.63 ± 0.09 and _N_g1 =

3.24 ± 0.17 (Fig. 3b). The shear modulus exhibits a similar power law $$K({N}_{{{{{{{{\rm{g}}}}}}}}})\propto {({N}_{{{{{{{{\rm{g}}}}}}}}}-{N}_{{{{{{{{\rm{g2}}}}}}}}})}^{-{\eta }_{2}},$$ (3)

with the fitted _η_2 = 0.72 ± 0.14 and _N_g2 = 3.07 ± 0.27 (Fig. 3c). The _σ_f and _K_ diverge at _N_g ≃ 3, indicating that the minimum grain size is at least 3 particles, which is

consistent with the extrapolated _N_g value at the random close-packing density in Fig. 2h where the stress diverges30. The divergence is caused by the hard-core interactions between

particles which render the system incompressible when the shells of soft particles collapse. Systems composed of soft-core particles can be infinitely compressed. In real systems, atoms

exhibit hard cores under high pressures. _σ_f(_N_g) and _K_(_N_g) derived from the plastic and elastic regimes are strikingly similar. Thus _σ_f(_K_) is linear (Fig. 3c inset). This

indicates that the solids with different grain sizes yield at the same strain, as confirmed in Supplementary Fig. 3 in which the slope of _σ_f(_γ_) always changes around _γ_ = 0.025. The

linear behaviour of _σ_f(_K_) is often observed in glasses28,31. The data for _x_ = 0.5 in Fig. 3b and d are from different trials of simulation, and both well fit Eq. (2). _σ_f(_N_g) at

other mixing ratios can also be well fitted by Eq. (2) (Fig. 3d) and can collapse well onto the master line after being rescaled by the fitting parameters (Fig. 3e). _K_(_N_g) at other

mixing ratios also exhibit similar results as Fig. 3c. The minimum grain sizes _N_g1,2 fitted from _σ_f(_N_g) and _K_(_N_g) are very close and can be reduced to three particles when the

fraction of soft particles _x_ ≥ 0.5 (Fig. 3f). This power-law strengthening holds at _N_g < 170 particles (Fig. 3b), i.e. _l_ < 3.5 nm for typical alloys. At _l_ > 3.5 nm, we

observe the conventional inverse Hall–Petch behaviour, see section “Polycrystal-glass transition” for details. A similar inverse pseudo Hall–Petch to pseudo Hall–Petch transition has been

recently reported at 3.1 nm in nanocrystalline graphene32, but there are only two data points at < 3.1 nm which can hardly provide a quantitative fitting. MICROSTRUCTURE CHANGES UNDER

SHEAR The structural deformation around particle _i_ is characterised by the mean squared nonaffine displacement17,33, $${D}_{i}^{2}=\frac{1}{{N}_{i}}\mathop{\sum }\limits_{j=1}^{{N}_{i}}|

{{{{{{{{\bf{d}}}}}}}}}_{ij}-{{{{{{{{\bf{F}}}}}}}}}_{i}{{{{{{{{\bf{d}}}}}}}}}_{ij}^{0}{| }^{2}$$ (4) which describes its neighbours’ average deviation from the linear strain field. D_i__j_ =

R_j_ − R_i_ is the distance vector between atom _i_ and its neighbour _j_ in the current state, \({{{{{{{{\bf{d}}}}}}}}}_{ij}^{0}\) is for the initial undeformed state, and F_i_ is the

transformation matrix for all distances between particle _i_ and its _N__i_ neighbours in a strain interval. Under shear (Fig. 4a–f), particles whose _D_2 > 0.6 usually signature local

plastic deformations33, i.e. STZs, which are labelled in yellow in Fig. 4h–k. These yellow particles are mainly found in amorphous regions and anti-correlate with crystalline regions (Fig.

4o). The Pearson correlation coefficients between quantities _A_ and _B_ is defined as \(C(A,B)=\frac{\mathop{\sum }\nolimits_{i}^{N}({A}_{i}-\langle A\rangle )({B}_{i}-\langle B\rangle

)}{\sqrt{\mathop{\sum }\nolimits_{i}^{N}{({A}_{i}-\langle A\rangle )}^{2}}\sqrt{\mathop{\sum }\nolimits_{i}^{N}{({B}_{i}-\langle B\rangle )}^{2}}}\), where 〈〉 averages over all the _N_

particles. In the elastic regime _γ_ < 0.025, plastic flows are absent (Fig. 4g). In the strain-hardening regime (0.025 ≤ _γ_ ≤ 0.2), the high-_D_2 yellow particles form small stripes

with a typical thickness of 2–4 particles. These localised plastic flows, i.e. STZs, homogeneously occur in space (Fig. 4h–j) because scattered crystallites interrupt their growth (Fig. 4a–f

and Supplementary Fig. 4b). By contrast, the plastic flows in normal glasses usually form extreme localised shear bands because no crystallite blocks the growth of STZs (Supplementary Fig.

4a). The extremely localised plastic flows in normal glasses often cause strain softening and even catastrophic failure, which limit their applications11,12. By contrast, the homogeneous

distribution of STZs in GCCs prevents the extreme localisation of plastic flow and leads to strain-hardening and associated strengthening effect (Fig. 3a, b)34. As _γ_ increases, the yellow

deformation zones grow and percolate the whole sample (Fig. 4k and Supplementary Fig. 4c) in the steady flow regime _γ_ > 0.25. Crystalline grains rotate (Fig. 4l), split (Fig. 4m), and

rebuild (Fig. 4n) during the deformation process (see Supplementary Movies 1–3), which continuously affect the plastic flow. Crystallites (high-∣_ϕ_6∣ regions) not only spatially

anticorrelate with strong-local-rearrangement (large _D_2) regions (Figs. 4o and 5a, b), but also tend to rotate clockwise, leading to more red clusters than blue clusters in Fig. 5c. This

rotation is consistent with the shear direction. The long-live neighbour particles can characterize the local structural rearrangement and reflect the macroscopic rheological response of

glasses from the microscopic structure35. Such analysis has been applied in colloidal gel36 and glass35, but rarely in GCCs or polycrystals. We find that plastic flows with high _D_2 (Fig.

5a) strongly correlate with particles having less long-lived neighbours (Fig. 5b). Crystalline particles have more long-lived neighbours than amorphous particles particularly at high _γ_

(Fig. 5d), indicating that more bond breakings occur in amorphous regions. Since the plastic deformations mainly occur in amorphous regions, the yield strain is a constant regardless of the

crystalline grain size (Fig. 3a and Supplementary Fig. 3). The shear-induced structure changes are shown in Fig. 6. The average crystalline order 〈∣_ψ_6∣〉 are nearly constant during plastic

deformation (Fig. 6a). The average 〈_D_2〉 of soft particles are greater than that of hard particles (Fig. 6b) and their ratio is constant in the plastic regime of _γ_ > 0.08 (Fig. 6c),

implying that a fixed large portion of deformation is obtained from the soft particles under shear. The deformation participation ratio

\({P}_{r}=\frac{1}{{N}_{{{{{{{{\rm{S,H}}}}}}}}}}\mathop{\sum }\nolimits_{i}^{{N}_{{{{{{{{\rm{S,H}}}}}}}}}}{{\Theta }}({D}_{i}^{2}-0.6)\), where _N_S,H is the numbers of soft or hard

particles and Θ is Heaviside function, i.e., the fraction of particles whose _D_2 > 0.6. Soft particles show larger _P__r_ than hard particles (Fig. 6d), which confirms their dominating

contribution to plastic flows. The spatially uniform distribution of soft particles (Supplementary Fig. 1) accounts for the homogeneity of STZs (Fig. 4e–k and Supplementary Fig. 4b, c) that

mitigate the extreme localisation of plastic flows (Supplementary Fig. 4a–c). The number of long-lived neighbouring particles _n_(_γ_) at different _ϕ_ or _N_g are almost the same for hard

particles, but different for soft particles (Fig. 6e). This finding is consistent with that shown in Fig. 5d, indicating that the plasticity mainly occurs on the soft particles distributed

in amorphous regions (Fig. 2e). _n_(_γ_) of soft particles decreases more rapidly in larger-grained GCCs (lower _ϕ_), implying that their local cages can be easily broken, and the stress can

be effectively released. Therefore, large-grained GCCs show weaker strain-hardening and strengthening effects (Fig. 3b, d). In contrast to strain softening in normal glasses, rejuvenated

glasses exhibit strain-hardening similar to our GCCs because they both exhibit uniform flow stresses. However, we find that their underlying mechanisms are different. For rejuvenated

glasses, the stored strain reduces the activation energy of STZ and causes uniform plastic flow with the decrease of energy34. For GCCs, however, the crystallites block the shear banding,

thereby producing a uniform plastic flow (Supplementary Fig. 4c) associated with a constant energy (Fig. 6f). POLYCRYSTAL-GLASS TRANSITION As grain size decreases small enough, a polycrystal

or a GCC will eventually become an amorphous glass. It is not clear whether an ultrafine grained polycrystal or GCC should be called as polycrystal or amorphous glass, or it is just a

matter of terminology without a clear distinction. This basic question has been rarely asked and poorly explored. Crystal-glass transition has been observed in colloidal37,38, granular39,40,

and atomic systems41,42, but these studies are neither about ultrafine-grained solids nor about the polycrystal-glass transition. Nanoindentation in Ni-W alloy shows that the deformation

morphology becomes similar to those in glasses when the grain size decreases to approximately 3 nm in the inverse Hall–Petch regimes9. However, whether this difference in deformation

morphology indicates a polycrystal-to-glass transition remains unclear9. For the hard–soft binary systems, surprisingly we find that polycrystal–glass transition occurs at a sharp point

rather than a gradual crossover10. Various quantities peak at _l_ ≃ 14 particles, i.e. _ϕ_ = 0.7 (Supplementary Fig. 5)10, which indicates a sharp polycrystal-glass transition. Therefore,

GCCs with _l_ < 14 particles can also be considered as dual-phase glasses (Fig. 1). The polycrystal–glass transition coincides with the transition between the inverse Hall–Petch softening

and the power-law strengthening regimes in Fig. 1. The maximum residual specific heat at _l_ = 14 particles (Supplementary Fig. 5a) implies the maximum fluctuation of compressed SS or SH

bonds, which is in accordance with the strongest fluctuations of structure and dynamics (Supplementary Fig. 5b, c). The maximum fluctuations of a structure parameter about crystallinity

(Supplementary Fig. 5b) and a dynamic parameter about vibration amplitude (Supplementary Fig. 5c) at _l_ = 14 particles imply the maximum compressibility as confirmed in Supplementary Fig.

5d, which is in accordance with the minimum strength at the boundary between the inverse Hall–Petch softening and power-law strengthening regimes (Fig. 1). Therefore, the features of the

polycrystal–glass transition10 can explain the transition between the inverse Hall–Petch softening and the power-law strengthening. In turn, the transition provides an additional signature

of the poorly explored polycrystal–glass transition. The system can be compressed into a glass when \((x-0.193)(0.786-\frac{1}{{\lambda }^{2}})\, > \,0.02\)10, i.e., the shoulder width

_λ_ and fraction of soft particles _x_ must be large enough to provide sufficient size mismatches for glass formation. The power-law strengthening regime (Fig. 1) can exists only in samples

whose _λ_ and _x_ satisfy the above inequality. For example, systems with small _λ_ or _x_ do not exhibit the strengthening regime because it is a polycrystal instead of a glass even under

the highest pressure (i.e. _ϕ_ = 0.83) in our simulation (see Supplementary Fig. 6). The classical Hall–Petch strengthening and inverse Hall–Petch softening indicate that the strongest

strength occurs at their boundary state. However, we observe the strength of GCCs can be six times higher than the boundary state between the Hall–Petch and inverse Hall–Petch regimes (Fig.

1). At _l_ ≃ 2, _σ_f = 0.3 in the reduced unit (Figs. 3b and 1) corresponds to _σ_f = 125 GPa for graphene, whose energy and distance units are _U_0 = 525 kJ mol−1 and _σ_ = 0.128 nm43,

respectively. Such _σ_f is higher than the strength of polycrystal graphene32,44,45,46. Therefore, the ultrafine-grained GCCs have the potential to achieve extremely high strength.

DISCUSSION Our simple system can model binary experimental systems whose components have different softness, such as alloys, granular and colloidal particles with different stiffness. For

instance in Al–Ce alloy, the 4f-electrons of Ce atom are localised and thus Ce atoms interact via shoulder potentials47, and their diameters can be reduced by 20% using cutting edge

high-pressure technologies48. Such large deformation is sufficient to induce the polycrystal–glass transition. In such binary systems, the grain size can be continuously decreased to a few

particles because the size-mismatched particles, i.e. the compressed soft particles, are gradually ‘added’ through the interior of the bulk by compression10. It is well known that adding

size-mismatched particles, i.e. solute particles, can reduce polycrystalline grain size8, but adding excessive solutes will produce glasses instead of ultrafine-grained polycrystal49. By

contrast, the solutes in our system are not added to the solution all at once, but incrementally added to the interior of the polycrystal, which hinders the glass formation. Thus, the

soft–hard binary system provides a full spectrum of grain size, which bridges the polycrystal and glass and enables to explore how the strength changes with grain size beyond the Hall–Petch

and inverse Hall–Petch regimes. We find that the inverse Hall–Petch softening terminates at _l_ ≃ 14 particles, i.e. 3.5 nm in typical alloys, and a strengthening regime develops at _l_ <

14 particles. The power-law strengthening regime in GCCs complements to the Hall–Petch and inverse Hall–Petch regimes for the grain size effect on solid strength (Fig. 1). We observe that

the strain-hardening and power-law strengthening arises from grain-mediated STZ, which is qualitatively different from the dislocation-mediated strengthening in the Hall–Petch relationship

(Fig. 1). The uniformly distributed crystalline grains in the amorphous matrix impede the growth of STZs, which suppress the formation of extreme localised shear band. Therefore, GCCs avoid

sudden stress drop that usually exists in normal glasses, and exhibit dramatic strengthening and strain-hardening which are absent in normal glasses. Moreover, we find that plastic

deformation arises from bond-breaking in the amorphous regions and collective cluster rotation in the crystalline regions. Crystalline grain rotations often lead to good ductility, which

explains the observed high ductility in dual-phase aluminium alloy22. This hardening mechanism avoids the inverse Hall–Petch softening in nanocrystal and the shear-band softening in glass,

thereby providing a route to improve the strength of materials. Low-dimensional systems are much softer because there are more long-wavelength fluctuations50 and particles have fewer

neighbour-provided constraints51. Consequently, the space dimension could affect the nature of phase transition such as crystal melting50,51 and glass dynamics52. For example, the transient

localization of particles on approaching the glass transition is absent in 2D, but very pronounced 3D52. Analysis based on local coordinates can avoid long-wavelength fluctuations so that

the glassy behaviours are similar in 2D and 3D53,54,55. We expect the strengthening beyond the inverse Hall–Petch (Fig. 1) remains valid in 3D because a completely disordered solid has a

higher strength than the polycrystals in the inverse Hall–Petch regime in 3D. This expectation is independent of the dimensionality. Various quantities of this binary system simultaneously

peak at the same _ϕ_ (Supplementary Fig. 5), which indicates a sharp polycrystal-to-glass transition point. In addition, we find that this polycrystal-glass transition point coincides with

the transition between the inverse Hall–Petch softening and power-law hardening. The features at the polycrystal-glass transition can qualitatively explains the softening–hardening

transition, and in turn, the softening-hardening transition provides an additional feature for the polycrystal-glass transition. The thermally induced transition and the nonequilibrium

shear-induced transition are qualitatively different and the shear could shift the transition point. However, the polycrystal-glass transition without shear coincides with the

softening–hardening transition with shear, which suggests deep connections between the material properties with and without shear. These results provide insights into the poorly explored

polycrystal-glass transition and the discovered softening–hardening transition. METHODS MODEL AND SIMULATION DETAILS The soft particle is described by square-shoulder potential

$$U(r)=\left\{\begin{array}{ll}\infty ,\quad &r\le \sigma \\ {U}_{0},\quad &\sigma\, < \,r\le \lambda \sigma \\ 0,\quad &\lambda \sigma\, < \,r\end{array}\right.$$ (5)

where _σ_ and _λ__σ_ are the diameters of the inner hard core and outer shoulder, respectively. In this work, _λ_ = 1.3. The energy unit _U_0 is the height of the shoulder. The pair

potential for hard particles is characterised as follows: $$\begin{array}{r}U(r)=\left\{\begin{array}{ll}\infty ,\quad &r\le \lambda \sigma \\ 0,\quad &\lambda \sigma\, <

\,r.\end{array}\right.\end{array}$$ (6) The square-shoulder potential has been used to describe cerium and cesium atoms, water and silica molecules, micelle and granular particles, and to

study self-assembly, glasses, quasicrystals, and photonic crystals47,56,57,58,59,60. We simulate _N_ = 12,800 particles under periodic boundary conditions with the fraction of soft particles

_x_ ranging from 0.35 to 0.6. The packing fraction _ϕ_ is defined as the area fraction of hard particles and the hard cores of soft particles: $$\phi =\frac{N\pi {\sigma

}^{2}}{4A}[(1-x){\lambda }^{2}+x],$$ (7) where _A_ is the area of the simulation box. Particles are randomly distributed in a low-density fluid (_ϕ_ = 0.5) state and then relaxed at

temperature _T_ = 2.0_U_0/_k_B. The relaxed systems are then compressed into polycrystal and glass (Supplementary Fig. 1) by using the Lubachevsky-Stillinger algorithm61. The resultant

systems are sufficiently equilibrated at _T_ = 0.13_U_0/_k_B for a time period of 105_t_0, where _k_B is the Boltzmann constant, \({t}_{0}=\sqrt{m{\sigma }^{2}/{U}_{0}}\) is the mean time

for a particle moving a distance _σ_, and _m_ is the unit of mass for hard and soft particles. All the results are measured at _T_ = 0.13_U_0/_k_B. After the system is compressed to the

desired _ϕ_ and its corresponding _N_g, a shear is applied along the _x_ direction by using the Lees-Edwards periodic condition in _y_ direction with a strain rate of 10−5. All figure and

movies are about samples with 50:50 soft–hard mixing ratio. Samples with other mixing ratios range from 35:65 to 60:40 exhibit similar results. Each simulation is repeated ten times for

sufficient statistics. IDENTIFICATION OF CRYSTALLINE GRAINS The local hexagonal order of particle _j_ is characterised by the weighted bond-orientational order parameter62 $${\psi

}_{6j}=\frac{1}{{l}_{{{{{{{{\rm{tot}}}}}}}}}}\mathop{\sum }\limits_{k=1}^{{N}_{j}}{l}_{jk}{e}^{i6{\theta }_{jk}},$$ (8) where _θ__j__k_ is the orientational angle of the bond between

particle _j_ and its neighbour _k_. _i_2 = − 1. The Voronoi polygon has _N__j_ edges with perimeter _l_tot, and the length of the edge between _j_ and _k_ is _l__j__k_. A higher ∣_ψ_6_j_∣

represents a higher 6-fold crystalline order. A crystalline bond is defined as \(| {\psi }_{6j}\cdot {\psi }_{6k}^{* }|\, > \,0.6\). A particle with three or more crystalline bonds is

defined as a crystalline particle63,64. Two neighbouring crystalline particles belong to the same grain if the difference between their orientational angle is less than 6∘. Non-crystalline

particles and single isolated crystalline particles are defined as disordered. The weighted mean grain size10,65 $${N}_{{{{{{{{\rm{g}}}}}}}}}=\sum

\frac{{n}_{s}{s}^{2}}{{N}_{{{{{{{{\rm{x}}}}}}}}}},$$ (9) where _n__s_ is the number of grains with _s_ crystalline particles; _N_x is the total number of crystalline particles; and

\(\frac{{n}_{s}s}{{N}_{{{{{{{{\rm{x}}}}}}}}}}\) is the probability that a particle belongs to the _s_-sized grains. The grain diameter \(l=\sqrt{{N}_{{{{{{{{\rm{g}}}}}}}}}}\). DATA

AVAILABILITY All the data used in this work are available on reasonable request from the corresponding author. CODE AVAILABILITY Computer codes used to generate the plots in this work are

available upon reasonable request via email to H.Z. REFERENCES * Hall, E. O. The deformation and ageing of mild steel: III discussion of results. _Proc. Phys. Soc. London B_ 64, 747 (1951).

Article ADS Google Scholar * Petch, N. J. The cleavage strength of polycrystals. _J. Iron Steel Inst._ 174, 25–28 (1953). Google Scholar * Cordero, Z. C., Knight, B. E. & Schuh, C.

A. Six decades of the Hall–Petch effect–a survey of grain-size strengthening studies on pure metals. _Int. Mater. Rev._ 61, 495–512 (2016). Article Google Scholar * Schiøtz, J. &

Jacobsen, K. W. A maximum in the strength of nanocrystalline copper. _Science_ 301, 1357–1359 (2003). Article ADS Google Scholar * Wu, J. et al. Mechanical instability of monocrystalline

and polycrystalline methane hydrates. _Nat. Commun._ 6, 8743 (2015). Article ADS Google Scholar * Hu, J., Shi, Y. N., Sauvage, X., Sha, G. & Lu, K. Grain boundary stability governs

hardening and softening in extremely fine nanograined metals. _Science_ 355, 1292–1296 (2017). Article ADS Google Scholar * Zhou, X. et al. High-pressure strengthening in

ultrafine-grained metals. _Nature_ 579, 67–72 (2020). Article ADS Google Scholar * Chookajorn, T., Murdoch, H. A. & Schuh, C. A. Design of stable nanocrystalline alloys. _Science_

337, 951–954 (2012). Article ADS Google Scholar * Trelewicz, J. R. & Schuh, C. A. The Hall–Petch breakdown in nanocrystalline metals: a crossover to glass-like deformation. _Acta

Mater._ 55, 5948–5958 (2007). Article ADS Google Scholar * Zhang, H. & Han, Y. Compression-induced polycrystal-glass transition in binary crystals. _Phys. Rev. X_ 8, 041023 (2018).

Google Scholar * Schuh, C. A., Hufnagel, T. C. & Ramamurty, U. Mechanical behavior of amorphous alloys. _Acta Mater._ 55, 4067–4109 (2007). Article ADS Google Scholar * Sun, B. A.

& Wang, W. H. The fracture of bulk metallic glasses. _Prog. Mater. Sci._ 74, 211–307 (2015). Article Google Scholar * Sun, Y. H., Concustell, A. & Greer, A. L. Thermomechanical

processing of metallic glasses: extending the range of the glassy state. _Nat. Rev. Mater._ 1, 16039 (2016). Article ADS Google Scholar * Chen, H., He, Y., Shiflet, G. J. & Poon, S.

J. Deformation-induced nanocrystal formation in shear bands of amorphous alloys. _Nature_ 367, 541–543 (1994). Article ADS Google Scholar * Greer, A. L., Cheng, Y. Q. & Ma, E. Shear

bands in metallic glasses. _Mater. Sci. Eng. R Rep._ 74, 71–132 (2013). Article Google Scholar * Krisponeit, J.-O. et al. Crossover from random three-dimensional avalanches to correlated

nano shear bands in metallic glasses. _Nat. Commun._ 5, 3616 (2014). Article ADS Google Scholar * Falk, M. L. & Langer, J. S. Dynamics of viscoplastic deformation in amorphous solids.

_Phys. Rev. E_ 57, 7192 (1998). Article ADS Google Scholar * Schall, P., Weitz, D. A. & Spaepen, F. Structural rearrangements that govern flow in colloidal glasses. _Science_ 318,

1895–1899 (2007). Article ADS Google Scholar * Puosi, F., Rottler, J. & Barrat, J.-L. Time-dependent elastic response to a local shear transformation in amorphous solids. _Phys. Rev.

E_ 89, 042302 (2014). Article ADS Google Scholar * Wu, G., Chan, K.-C., Zhu, L., Sun, L. & Lu, J. Dual-phase nanostructuring as a route to high-strength magnesium alloys. _Nature_

545, 80–83 (2017). Article ADS Google Scholar * Hua, P., Xia, M., Onuki, Y. & Sun, Q. Nanocomposite NiTi shape memory alloy with high strength and fatigue resistance. _Nat.

Nanotechnol._ 16, 409–413 (2021). Article ADS Google Scholar * Wu, G. et al. Hierarchical nanostructured aluminum alloy with ultrahigh strength and large plasticity. _Nat. Commun._ 10,

5099 (2019). Article ADS Google Scholar * Wang, W. H. Dynamic relaxations and relaxation-property relationships in metallic glasses. _Prog. Mater. Sci._ 106, 100561 (2019). Article

Google Scholar * Şopu, D., Stukowski, A., Stoica, M. & Scudino, S. Atomic-level processes of shear band nucleation in metallic glasses. _Phys. Rev. Lett._ 119, 195503 (2017). Article

ADS Google Scholar * Parmar, A. D. S., Kumar, S. & Sastry, S. Strain localization above the yielding point in cyclically deformed glasses. _Phys. Rev. X_ 9, 021018 (2019). Google

Scholar * Bannerman, M. N., Sargant, R. & Lue, L. Dynamo: a free general event-driven molecular dynamics simulator. _J. Comput. Chem._ 32, 3329–3338 (2011). Article Google Scholar *

Warren, B. E. X-ray Diffraction (New York: Dover Publications Inc., 1990). * Cheng, Y. Q. & Ma, E. Atomic-level structure and structure–property relationship in metallic glasses. _Prog.

Mater. Sci._ 56, 379–473 (2011). Article Google Scholar * Nie, Y., Liu, J., Guo, J. & Xu, N. Connecting glass-forming ability of binary mixtures of soft particles to equilibrium

melting temperatures. _Nat. Commun._ 11, 3198 (2020). Article ADS Google Scholar * Jin, Y., Urbani, P., Zamponi, F. & Yoshino, H. A stability-reversibility map unifies elasticity,

plasticity, yielding, and jamming in hard sphere glasses. _Sci. Adv._ 4, eaat6387 (2018). Article ADS Google Scholar * Johnson, W. & Samwer, K. A universal criterion for plastic

yielding of metallic glasses with a (t/t g) 2/3 temperature dependence. _Phys. Rev. Lett._ 95, 195501 (2005). Article ADS Google Scholar * Han, J. The transition from an inverse pseudo

hall-petch to a pseudo hall-petch behavior in nanocrystalline graphene. _Carbon_ 161, 542–549 (2020). Article Google Scholar * Cao, P., Short, M. P. & Yip, S. Potential energy

landscape activations governing plastic flows in glass rheology. _Proc. Natl. Acad. Sci. U.S.A._ 116, 18790–18797 (2019). Article ADS Google Scholar * Pan, J., Ivanov, Y. P., Zhou, W. H.,

Li, Y. & Greer, A. L. Strain-hardening and suppression of shear-banding in rejuvenated bulk metallic glass. _Nature_ 578, 559–562 (2020). Article ADS Google Scholar * Laurati, M.,

Maßhoff, P., Mutch, K. J., Egelhaaf, S. U. & Zaccone, A. Long-lived neighbors determine the rheological response of glasses. _Phys. Rev. Lett._ 118, 018002 (2017). Article ADS Google

Scholar * Nabizadeh, M. & Jamali, S. Life and death of colloidal bonds control the rate-dependent rheology of gels. _Nat. Commun._ 12, 4274 (2021). Article ADS Google Scholar * Zhao,

K. & Mason, T. G. Frustrated rotator crystals and glasses of brownian pentagons. _Phys. Rev. Lett._ 103, 208302 (2009). Article ADS Google Scholar * Yunker, P., Zhang, Z. & Yodh,

A. G. Observation of the disorder-induced crystal-to-glass transition. _Phys. Rev. Lett._ 104, 015701 (2010). Article ADS Google Scholar * Shen, H., Tong, H., Tan, P. & Xu, L. A

universal state and its relaxation mechanisms of long-range interacting polygons. _Nat. Commun._ 10, 1–8 (2019). Article Google Scholar * Zhou, C.-C., Shen, H., Tong, H., Xu, N. & Tan,

P. Coupling between particle shape and long-range interaction in the high-density regime. _Chin. Phys. Lett._ 37, 086301 (2020). Article ADS Google Scholar * Deb, S. K., Wilding, M.,

Somayazulu, M. & McMillan, P. F. Pressure-induced amorphization and an amorphous–amorphous transition in densified porous silicon. _Nature_ 414, 528–530 (2001). Article ADS Google

Scholar * Wang, Y.-C. et al. In situ tem study of deformation-induced crystalline-to-amorphous transition in silicon. _NPG Asia Materials_ 8, e291–e291 (2016). Article Google Scholar *

Bourque, A. J. & Rutledge, G. C. Empirical potential for molecular simulation of graphene nanoplatelets. _J. Chem. Phys._ 148, 144709 (2018). Article ADS Google Scholar * Song, Z.,

Artyukhov, V. I., Yakobson, B. I. & Xu, Z. Pseudo Hall-Petch strength reduction in polycrystalline graphene. _Nano Lett._ 13, 1829–1833 (2013). Article ADS Google Scholar * Sha, Z. D.

et al. Inverse pseudo Hall-Petch relation in polycrystalline graphene. _Sci. Rep._ 4, 5991 (2014). Article Google Scholar * Chen, M. et al. Effects of grain size, temperature and strain

rate on the mechanical properties of polycrystalline graphene – a molecular dynamics study. _Carbon_ 85, 135–146 (2015). Article Google Scholar * Young, D. A. & Alder, B. J.

Melting-curve extrema from a repulsive “step" potential. _Phys. Rev. Lett._ 38, 1213–1216 (1977). Article ADS Google Scholar * Zeng, Q. S. et al. Long-range topological order in

metallic glass. _Science_ 332, 1404–1406 (2011). Article ADS Google Scholar * T. Egami, Y. W. Atomic size effect on the formability of metallic glasses. _J. Non-Cryst. Solids_ 64, 113–134

(1984). Article ADS Google Scholar * Strandburg, K. J. Two-dimensional melting. _Rev. Mod. Phys._ 60, 161 (1988). Article ADS Google Scholar * Wang, F., Zhou, D. & Han, Y. Melting

of colloidal crystals. _Adv. Funct. Mater._ 26, 8903–8919 (2016). Article Google Scholar * Flenner, E. & Szamel, G. Fundamental differences between glassy dynamics in two and three

dimensions. _Nat. Commun._ 6, 7392 (2015). Article ADS Google Scholar * Shiba, H., Yamada, Y., Kawasaki, T. & Kim, K. Unveiling dimensionality dependence of glassy dynamics: 2d

infinite fluctuation eclipses inherent structural relaxation. _Phys. Rev. Lett._ 117, 245701 (2016). Article ADS Google Scholar * Vivek, S., Kelleher, C. P., Chaikin, P. M. & Weeks,

E. R. Long-wavelength fluctuations and the glass transition in two dimensions and three dimensions. _Proc. Natl. Acad. Sci. U.S.A._ 114, 1850–1855 (2017). Article ADS Google Scholar *

Illing, B. et al. Mermin–wagner fluctuations in 2d amorphous solids. _Proc. Natl. Acad. Sci. U.S.A._ 114, 1856–1861 (2017). Article ADS Google Scholar * Malescio, G. & Pellicane, G.

Stripe phases from isotropic repulsive interactions. _Nat. Mater._ 2, 97–100 (2003). Article ADS Google Scholar * Osterman, N., Babič, D., Poberaj, I., Dobnikar, J. & Ziherl, P.

Observation of condensed phases of quasiplanar core-softened colloids. _Phys. Rev. Lett._ 99, 248301 (2007). Article ADS Google Scholar * Sperl, M., Zaccarelli, E., Sciortino, F., Kumar,

P. & Stanley, H. E. Disconnected glass-glass transitions and diffusion anomalies in a model with two repulsive length scales. _Phys. Rev. Lett._ 104, 145701 (2010). Article ADS Google

Scholar * Dotera, T., Oshiro, T. & Ziherl, P. Mosaic two-lengthscale quasicrystals. _Nature_ 506, 208–211 (2014). Article ADS Google Scholar * Pattabhiraman, H., Avvisati, G. &

Dijkstra, M. Novel pyrochlorelike crystal with a photonic band gap self-assembled using colloids with a simple interaction potential. _Phys. Rev. Lett._ 119, 157401 (2017). Article ADS

Google Scholar * Stillinger, F. H. & Lubachevsky, B. D. Crystalline-amorphous interface packings for disks and spheres. _J. Stat. Phys._ 73, 497–514 (1993). Article ADS MathSciNet

MATH Google Scholar * Mickel, W., Kapfer, S. C., Schröder-Turk, G. E. & Mecke, K. Shortcomings of the bond orientational order parameters for the analysis of disordered particulate

matter. _J. Chem. Phys._ 138, 044501 (2013). Article ADS Google Scholar * Rein ten Wolde, P., Ruiz-Montero, M. J. & Frenkel, D. Numerical calculation of the rate of crystal nucleation

in a lennard-jones system at moderate undercooling. _J. Chem. Phys._ 104, 9932–9947 (1996). Article ADS Google Scholar * Peng, Y. et al. Two-step nucleation mechanism in solid–solid

phase transitions. _Nat. Mater._ 14, 101–108 (2015). Article ADS Google Scholar * Stauffer, D. & Aharony, A. Introduction to Percolation Theory (CRC press, 1994). * Desmond, K. W.

& Weeks, E. R. Random close packing of disks and spheres in confined geometries. _Phys. Rev. E_ 80, 051305 (2009). Article ADS Google Scholar * Shi, Y. & Falk, M. L. Strain

localization and percolation of stable structure in amorphous solids. _Phys. Rev. Lett._ 95, 095502 (2005). Article ADS Google Scholar Download references ACKNOWLEDGEMENTS We thank Zhibin

Xu, Zhenwei Wu and Pengfei Guan for helpful discussions. This work was supported by the Fundamental Research Funds for the Central Universities (H.Z.: grant No. xxj032021001), the Key

R&D Project of Shaanxi Province (H.Z.: grant No. 2022GY-400), the National Natural Science Foundation of China (H.Z.: grant No. 12274336), 111 Project 2.0 (G.U.: grant No. BP2018008),

the Strategic Priority Research Program of the Chinese Academy of Sciences (Z.Z.: grant No. XDB22040301), the Guangdong Basic and Applied Basic Research Foundation (Y.H.: grant No.

2020B1515120067), and the Hong Kong Research Grants Council under the General Research Fund (Y.H.: grant No. CRF-C6016-20G, C6021-19EF). AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * State

Key Laboratory for Mechanical Behaviour of Materials, Shaanxi International Research Center for Soft Matter, School of Materials Science and Engineering, Xi’an Jiaotong University, Xi’an,

710049, China Huijun Zhang, Feng Liu & Goran Ungar * Department of Materials Science and Engineering, University of Sheffield, Sheffield, UK Goran Ungar * Institute of Mechanics, Chinese

Academy of Sciences, School of Engineering Science, University of Chinese Academy of Sciences, Beijing, China Zhongyu Zheng * Department of Mechanical and Aerospace Engineering, Hong Kong

University of Science and Technology, Clear Water Bay, Hong Kong, China Qingping Sun * Department of Physics, Hong Kong University of Science and Technology, Clear Water Bay, Hong Kong,

China Yilong Han * Hong Kong University of Science and Technology Shenzhen Research Institute, Shenzhen, 518057, China Yilong Han Authors * Huijun Zhang View author publications You can also

search for this author inPubMed Google Scholar * Feng Liu View author publications You can also search for this author inPubMed Google Scholar * Goran Ungar View author publications You can

also search for this author inPubMed Google Scholar * Zhongyu Zheng View author publications You can also search for this author inPubMed Google Scholar * Qingping Sun View author

publications You can also search for this author inPubMed Google Scholar * Yilong Han View author publications You can also search for this author inPubMed Google Scholar CONTRIBUTIONS H.Z.

and Y.H. conceived the project. H.Z. performed the simulation and the data analyses. H.Z., F.L., G.U., Z.Z., Q.S. and Y.H. discussed the results and contributed to the explanations. H.Z. and

Y.H. wrote the manuscript. CORRESPONDING AUTHORS Correspondence to Huijun Zhang or Yilong Han. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing interests. PEER

REVIEW PEER REVIEW INFORMATION _Communications Physics_ thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available. ADDITIONAL

INFORMATION PUBLISHER’S NOTE Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. SUPPLEMENTARY INFORMATION PEER REVIEW

FILE SUPPLEMENTARY INFORMATION DESCRIPTION OF ADDITIONAL SUPPLEMENTARY FILES SUPPLEMENTARY MOVIE 1 SUPPLEMENTARY MOVIE 2 SUPPLEMENTARY MOVIE 3 RIGHTS AND PERMISSIONS OPEN ACCESS This article

is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you

give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material

in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative

Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a

copy of this license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Zhang, H., Liu, F., Ungar, G. _et al._ A regime beyond

the Hall–Petch and inverse-Hall–Petch regimes in ultrafine-grained solids. _Commun Phys_ 5, 329 (2022). https://doi.org/10.1038/s42005-022-01107-7 Download citation * Received: 07 April 2022

* Accepted: 01 December 2022 * Published: 15 December 2022 * DOI: https://doi.org/10.1038/s42005-022-01107-7 SHARE THIS ARTICLE Anyone you share the following link with will be able to read

this content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative